30 Years Experience Coating Line Turnkey System Integrator

Tel: +86 13580616025

Attractivechina New Metal Coating Machinery Custom Automatic Coating Line Metal Electrostatic Powder Coating Line

Category:

Technology at home and abroad

Quality assurance

Tailored

Original purchase

Get quote

- Product Details

-

- Brand: Attractivechina

- Commodity name: Attractivechina New Metal Coating Machinery Custom Automatic Coating Line Metal Electrostatic Powder Coating Line

- Commodity ID: Attractivechina2024013004

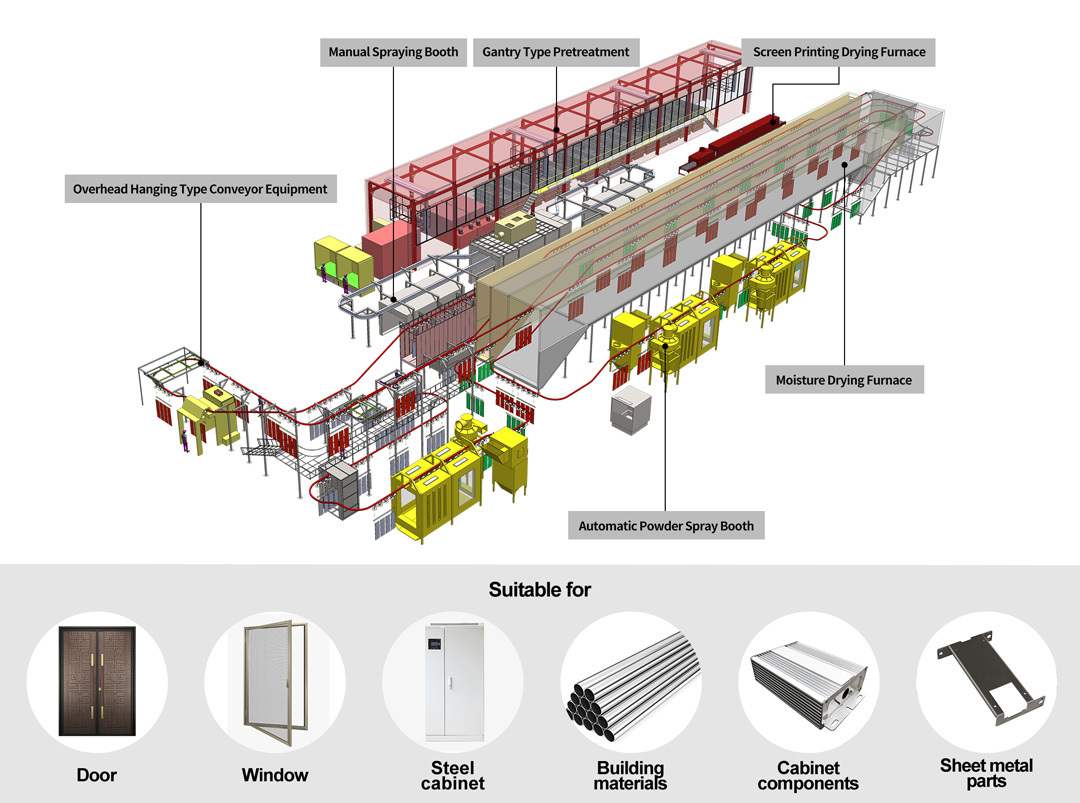

This metal coating line is not only suitable for various types of hardware products, such as doors and windows, furniture, lamps, cabinet shells, sheet metal parts, etc., but can also be adapted to a variety of coating materials, such as water-based paint, powder coating, baking paint, etc., to achieve Diverse painting needs.

Metal Coating Line

1. Automatic transmission, speed up to 8m/min, high production efficiency.

2. before spraying, dust removal process to ensure surface does not exist > 0.1mm dust.

3. The pre-heat treatment of dehumidification treatment, no oil and water marks on the surface, and increase the adsorption effect of the paint.

4. Wonderful and accurate surface coating, qualified rate is more than 95%.

5. Imported painting pump, imported spray gun and high precision flow ratio valve, save 30% paint material.

6. The air supply through 4 filters, ensure that the dustless spray room meets the dust free level standard.

7. Paint mist removal system: centrifugal mist exhaust fan, exhaust the mist in 2 seconds.

8. PLC central control system, automation control, one button operation, convenient and safe.

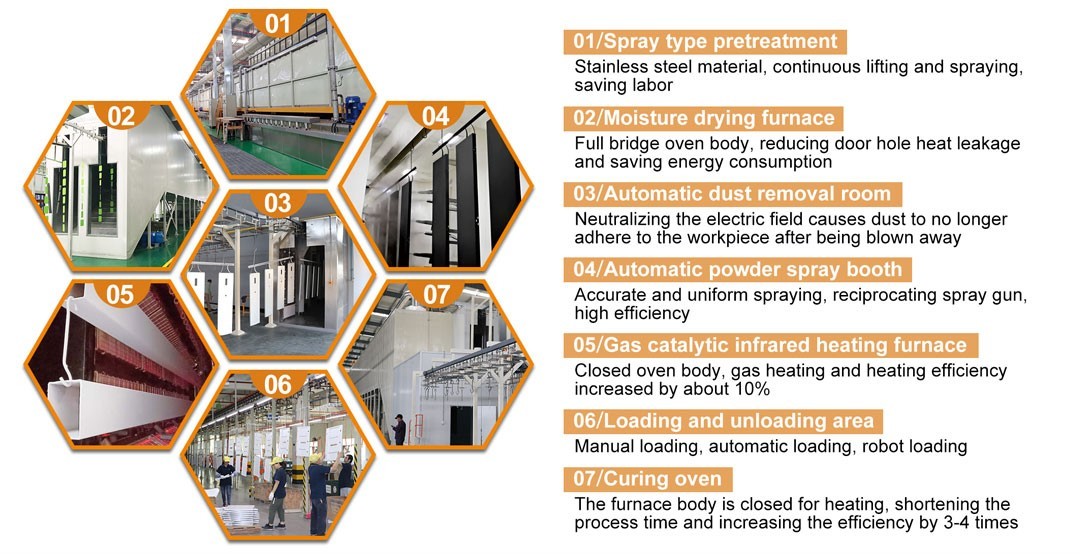

Technological Process

Metal Coating Line

Loading→Hot rinsing→Pre-degreasing→Degreasing→Spraying rinse→Pottery→Spraying rinse→Manual water blowing /dripping→Moisture drying→Natural cooling→Inspection area→Transfer /offline polishing→Dedusting→Primer powder spraying→Primer powder curing→Cooling→Electrostatic dust removal→Top powder spraying→Top powder curing→Natural cooling→Unloading

Device Parameters

Workpiece: Door, window, steel cabinet, building materials, cabinet components, sheet metal parts etc.

Workpiece material: Iron, galvanized

Work system: 300 days/year; 22H/day; equipment utilization rate: 85%

Spraying method: Robot + manual powder spraying + reciprocating machine

Maximum workpiece size of suspension line:3000mm(L)x1000mm(W)x1800mm(H) 1mm/Hang

Suspension line conveying method: 250 type double guide roller conveyor chain

Chain pitch of suspension line: 250mm

Hanging line workpiece pitch: 3500mm

Hanging wire hanging method: Double point hanging, single point lifting weight 50kg

Maximum workpiece production capacity : 68 pieces/H, 1496 pieces/day, 44.88 × 8500 pieces/year

Conveyor speed: 4000mm/min(2000-5000mm/min Adjustable)

Length of conveyor belt: About 363M

Net height of factory building: 13m(H)

Power: 380V 3φ 50 Hz

Compressed air: Pressure≥0.7MPa±5%、oil<0.01mg/m³、solid <1.00mg/m³、dew point 0.6Mpa -20℃

Natural gas: Standard pressure is medium pressure 80kPa

Tap water: Pressure≥1.5Kg/㎝2

Heating energy: Electricity, natural gasNote: Above data for reference only, the actual data will be calculated according to customer require

Our Team

Exhibition Site

Customer Photo

Our Partners

Attractivechina has been focusing on the painting industry since 1994 and has been doing so for 30 years. With its good reputation, it is highly favored in domestic and international markets, and its products are exported to countries and regions such as Thailand, Vietnam, India, Indonesia, Iran, Bangladesh, Singapore, Russia, Pakistan, the United States, Mexico, etc.

FAQ

1. Are you a trading company or a factory?

We are a coating line equipment manufacturer; we can provide turnkey solution service for your products.

2. If interested in your coating equipment, what should I provide?

A. Product’s material/size (standard and maximum)/weight (standard and maximum)?

B. What is the daily output (1 day=8 hours, 1 month=30 days)?

C. Which heating method do you prefer: electricity, gas, diesel or others?

D. What is the area of your factory (length, width, and height)?

3. Additional service

We will provide the overall design scheme for free before you place the order. After obtaining the approval by both parties, we will prepare the detail technical specification and quotation.

4. Price

The price on website is not the actual price, because it is a customized product, the product process flow is different and the price will be different. The final quotation is based on the confirmed technical specification.

5. Payment method

For stock products, small, medium and large size equipment, the whole coating system 40% of the total amount as deposit shall be paid in advance. After inspection and acceptance by customer, 50% of the total amount shall be paid before shipment. The balance shall be settled after installation and training. The actual payment terms can be negotiated according to different situations.

6. Lead time

We are a professional manufacturer of non-standard customized coating equipment. To ensure the provision of high-quality products and services, we have set the delivery cycle at 60-90 working days. The actual delivery cycle depends on the order and actual production plan.

7. Packing

The default packaging of domestic and oversea shipment is white protective film and drag reducing foam packaging. The packaging of export goods is customized package or fumigation free wooden pallet and wooden case. It meets the exporting standards, firm and safe.

8. Shipment

We usually adopt the trading mode as EXW or FOB (Guangdong port), customer can also specify a logistic company.

9. Installation and training

If possible, the customer can arrange employees to come to our company for training. We will assign the relevant technicians to your factory for installation supervision until the trial production is completed. In addition, we are very pleasure to share the maintenance skill.

10. After-sale Service

The main accessories of coating system are warranty for one year. The spare parts are free during the warranty period (except the vulnerable parts and human factors). After the warranty period, you can extend the maintenance period by maintenance contract. We will provide you with the lifelong free professional technical consulting services too.Key words:- hardware automatic coating line

- spray machine

- Metal coating equipment

Equipment

Related products

undefined