30 Years Experience Coating Line Turnkey System Integrator

Tel: +86 13580616025

Attractivechina activated carbon filter waste gas treatment equipment

Category:

Technology at home and abroad

Quality assurance

Tailored

Original purchase

Get quote

- Product Details

-

- Brand: Attractivechina

- Commodity name: Attractivechina activated carbon filter waste gas treatment equipment

- Commodity ID: 1049255430514892800

1. Low consumption, low greenhouse effect, stable and reliable operation, low failure rate, easy maintenance, low operating costs; 2. Treatment process for exhaust gases, suit for a variety of exhaust gases. Reduce pollution problems. 3. Outdoor or indoor type of equipment. It can effectively prevent wind, rain, frost and rust. 4. No neutralizer, covering flux and other chemicals are used during equipment operation. 5. Stainless steel material with the service life is long. The equipment is easy to move and almost no loss.

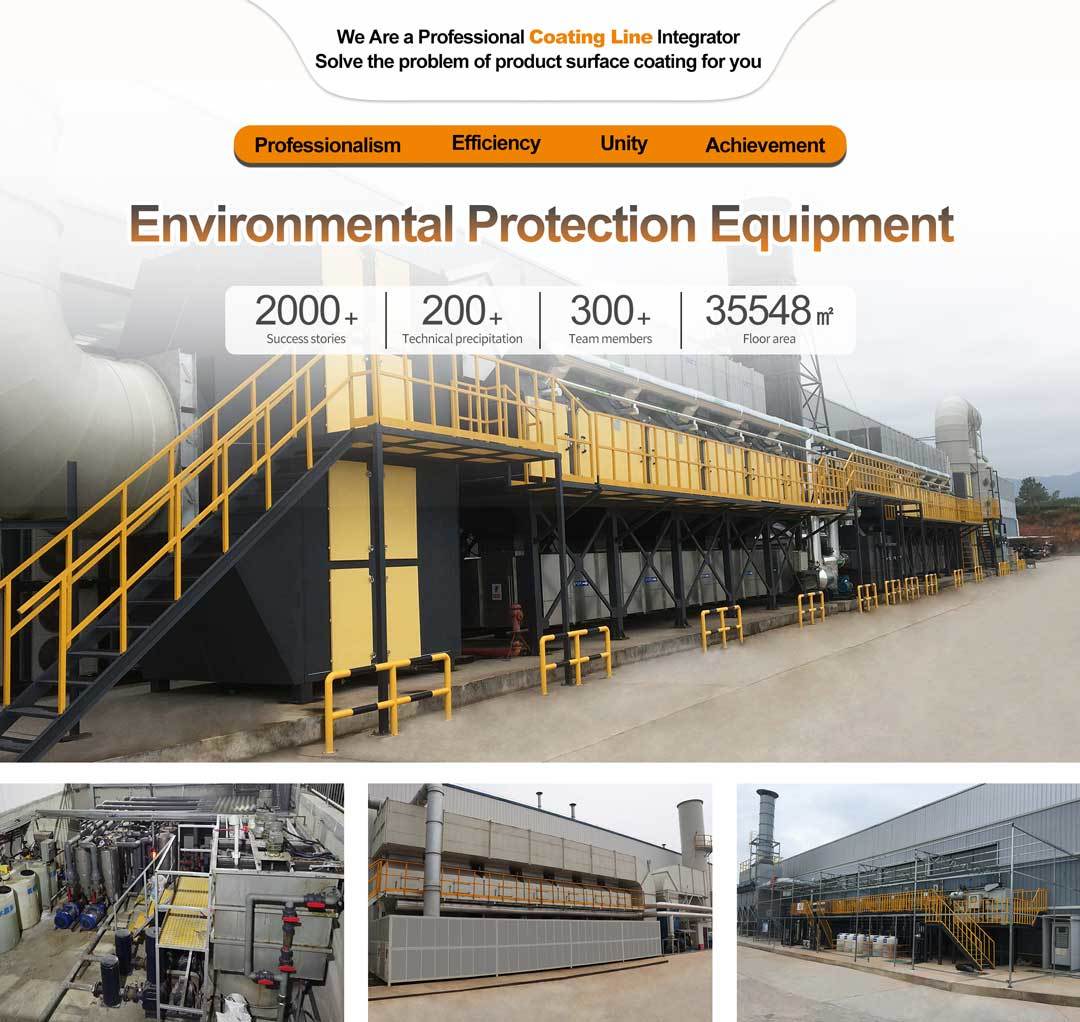

Environmental Protection Equipment

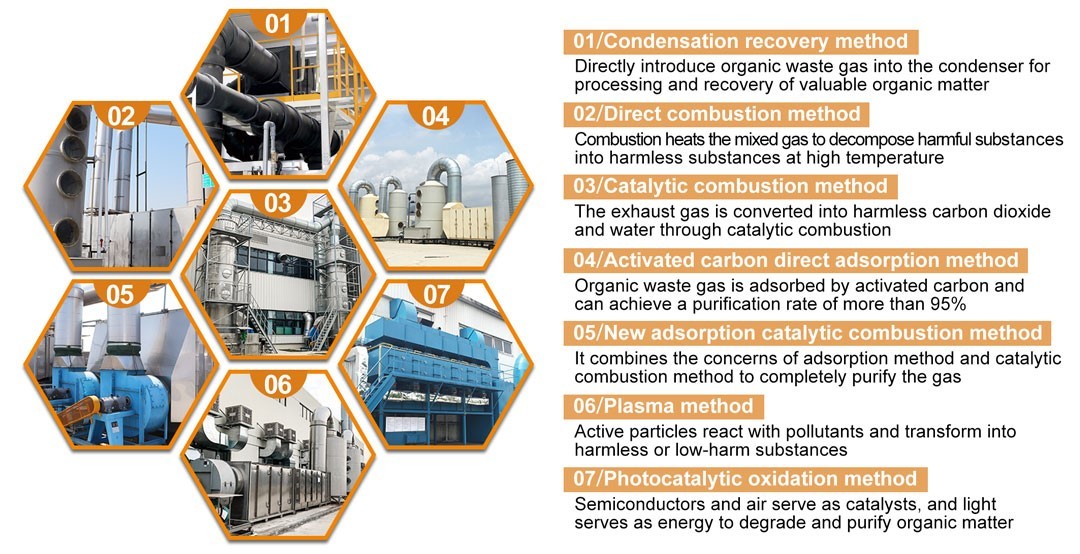

1. High purification rate: The purification rate exceeds 90%, and it meets environmental protection emission standards after chemical treatment.

2. Strong processing capacity: can handle benzene, toluene, dimethyl, ether, cyclopropanone and other pollutants

3. Low operating costs: operating costs are lower than 50% of similar organic waste gas treatment equipment on the market

4. Low consumption, low greenhouse effect, stable and reliable operation, low failure rate, easy maintenance, low operating costs;

5. Treatment process for exhaust gases, suit for a variety of exhaust gases. Reduce pollution problems.

6. Outdoor or indoor type of equipment. It can effectively prevent wind, rain, frost and rust.

7. No neutralizer, covering flux and other chemicals are used during equipment operation.

8. Stainless steel material with the service life is long. The equipment is easy to move and almost no loss.

Device Parameters

Equipment materials: Stainless steel Power supply: AC220V.50HZ/380V.50H

Water source: Tap water (1.5KG/npg) Net gas volume: 18000m³/H

Energy used: Electricity, natural gas Quality certification: ISO9001:2015

Size: W2400*L2500*H2500 Environmental certification: ISO14001:2015

Water pump flow: 660L/min Non-standard customization: Support

Note: Above data for reference only, the actual data will be calculated according to customer require

Our Team

Exhibition Site

Customer Photo

Our Partners

Attractivechina has been focusing on the painting industry since 1994 and has been doing so for 30 years. With its good reputation, it is highly favored in domestic and international markets, and its products are exported to countries and regions such as Thailand, Vietnam, India, Indonesia, Iran, Bangladesh, Singapore, Russia, Pakistan, the United States, Mexico, etc.

FAQ

1. Are you a trading company or a factory?

We are a coating line equipment manufacturer; we can provide turnkey solution service for your products.

2. If interested in your coating equipment, what should I provide?

A. Product’s material/size (standard and maximum)/weight (standard and maximum)?

B. What is the daily output (1 day=8 hours, 1 month=30 days)?

C. Which heating method do you prefer: electricity, gas, diesel or others?

D. What is the area of your factory (length, width, and height)?

3. Additional service

We will provide the overall design scheme for free before you place the order. After obtaining the approval by both parties, we will prepare the detail technical specification and quotation.

4. Price

The price on website is not the actual price, because it is a customized product, the product process flow is different and the price will be different. The final quotation is based on the confirmed technical specification.

5. Payment method

For stock products, small, medium and large size equipment, the whole coating system 40% of the total amount as deposit shall be paid in advance. After inspection and acceptance by customer, 50% of the total amount shall be paid before shipment. The balance shall be settled after installation and training. The actual payment terms can be negotiated according to different situations.

6. Lead time

We are a professional manufacturer of non-standard customized coating equipment. To ensure the provision of high-quality products and services, we have set the delivery cycle at 60-90 working days. The actual delivery cycle depends on the order and actual production plan.

7. Packing

The default packaging of domestic and oversea shipment is white protective film and drag reducing foam packaging. The packaging of export goods is customized package or fumigation free wooden pallet and wooden case. It meets the exporting standards, firm and safe.

8. Shipment

We usually adopt the trading mode as EXW or FOB (Guangdong port), customer can also specify a logistic company.

9. Installation and training

If possible, the customer can arrange employees to come to our company for training. We will assign the relevant technicians to your factory for installation supervision until the trial production is completed. In addition, we are very pleasure to share the maintenance skill.

10. After-sale Service

The main accessories of coating system are warranty for one year. The spare parts are free during the warranty period (except the vulnerable parts and human factors). After the warranty period, you can extend the maintenance period by maintenance contract. We will provide you with the lifelong free professional technical consulting services too.Key words:- UV photolysis

- activated carbon filter

- waste gas treatment equipment

Equipment

Related products

undefined