编号 :

Attractivechina2025081419

Painting Spray Equipment Non Stick Cookware Coating Machine Paint Coating Production Line

零售价

市场价

Technology at home and abroad

Quality assurance

Tailored

Original purchase

SEO:

全国客户服务热线 7*24小时:

+86 758-6626158-8063

重量

库存

隐藏域元素占位

- Product Details

- Product Parameters

- Product Properties

-

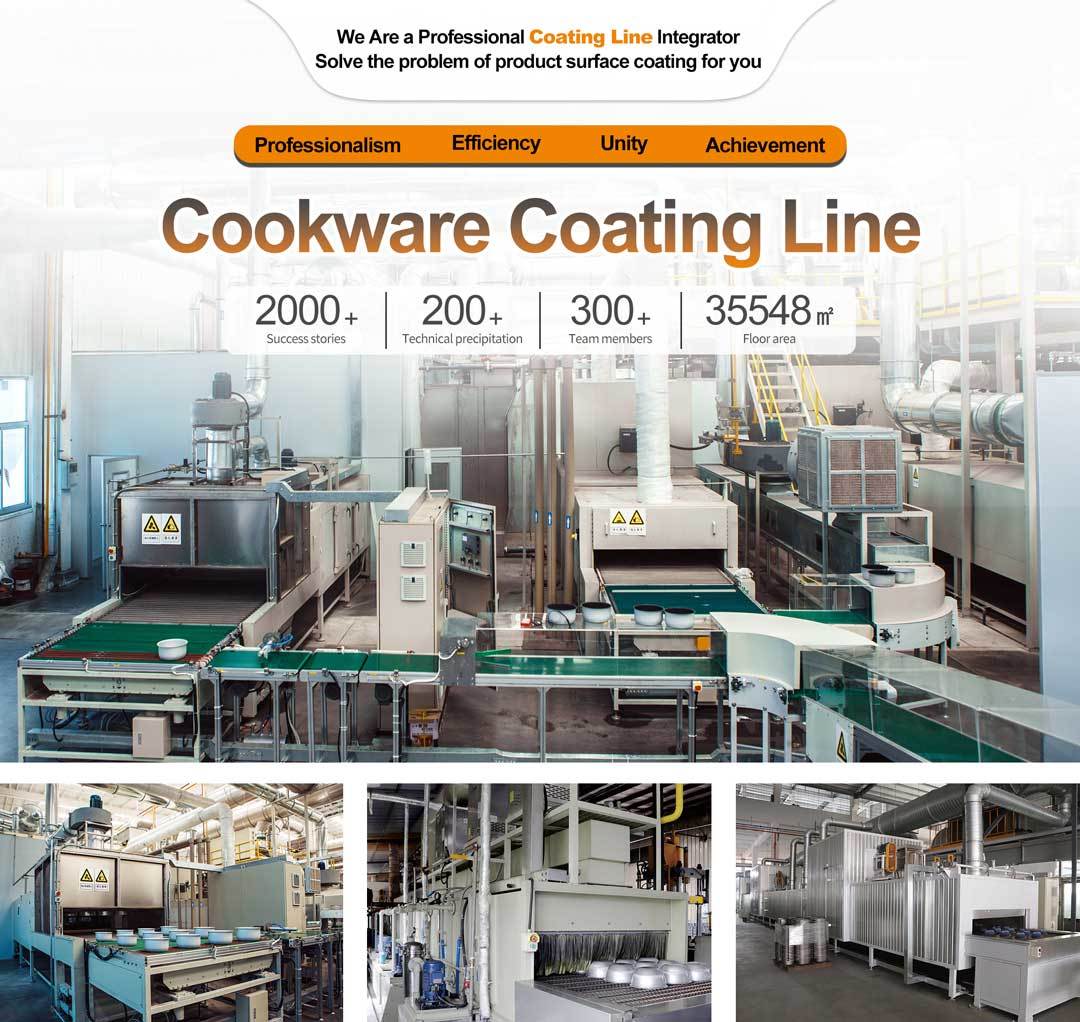

Cookware Coating Line

Our cookware coating production line is efficient, stable and automated, which can improve customers' production efficiency and product quality. Whether you are a large cookware manufacturer or a small factory, we can provide you with the best solution.

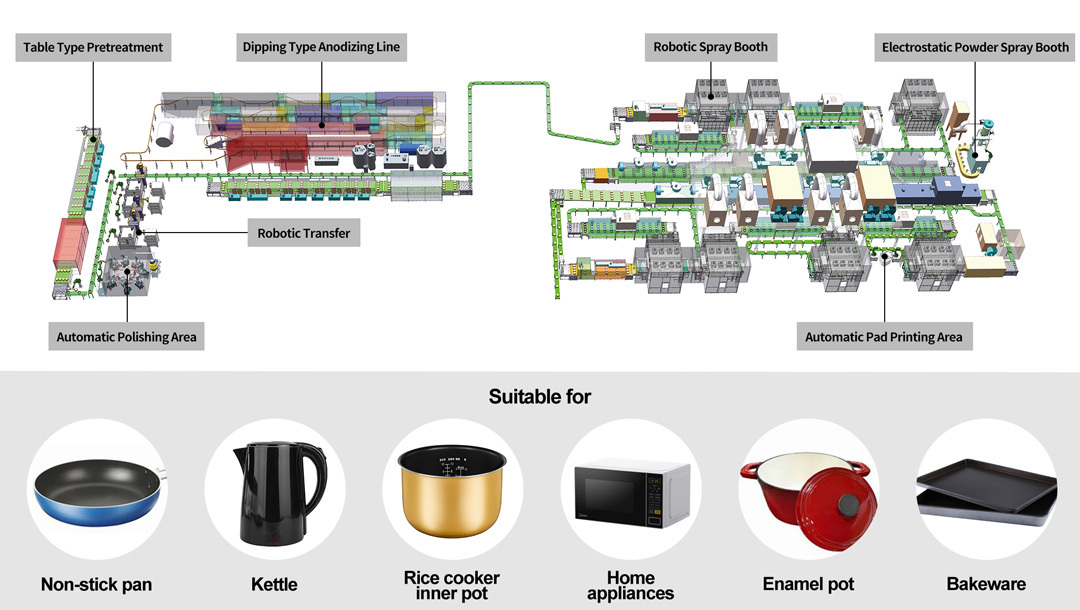

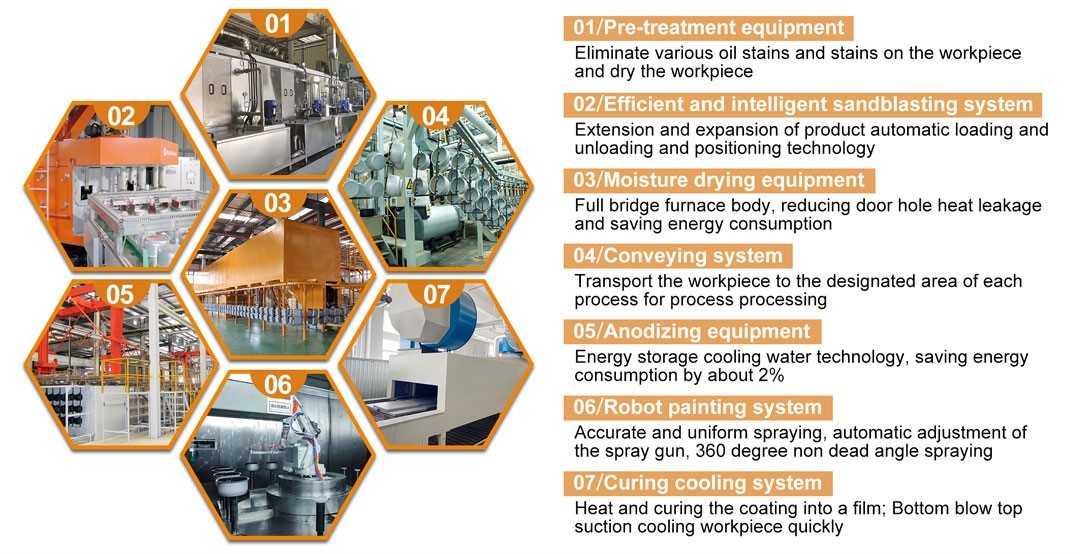

Technological Process

Pretreatment production line

Loading→Hot rinsing→Pre-degreasing→Degreasing→Rinsing→Direct spraying by pure water→Blow water→Drying→Cooling→Sand blasting→Rinsing desanding→Alkali corrosion→Rinsing→Neutralization→Rinsing→DI rinsing→Blow water→Drying→Cooling→Transfer

Ordinary anodizing technology

Loading→Pre-degreasing→Degreasing→Rinsing→Alkali corrosion→Rinsing→Neutralization→Rinsing→Direct spraying by pure water→Oxidation→Rinsing→Sealing→DI rinsing→Drying→Cooling→Unloading

Inner pot coating line process

Loading→Automatic dedusting→Pre-heating→Primer spraying→Primer drying→Cooling→Inner pot→Water level markpad printing→Pre-heating→Powder spraying→High temperature curing→Cooling→Unloading

Outer pot coating line process

Loading→Automatic dedusting→Pre-heating→Primer spraying→Primer drying→Cooling→Outer pot→Top-coat spraying→Top-coat drying→Cooling→High temperature curing→Cooling→Unloading

-

Workpiece: Non-stick pan,kettle,rice cooker inner pot,home appliances,enamel pot,bakeware, etc. Workpiece material: Aluminum alloy, composite material (stainless steel, aluminum alloy, copper, etc.) Work system: 300 days/year; 20H/day; equipment utilization rate: 85% Spray booth temperature: 18~26°C Spray room humidity: 45~75%RH Spraying method: Fixed gun/robot Workpiece size: Ф130~300 mm*160H Production output: 800 pieces/hour Power: 380V 3φ 50 Hz Compressed air: Pressure≥0.7MPa±5% oil<0.01mg/m³ solid <1.00mg/m³ dew point 0.6Mpa -20℃ Natural gas: Standard pressure is medium pressure 80kPa Tap water: Pressure≥1.5Kg/㎝2 Heating energy: Electricity, natural gas Note: Above data for reference only, the actual data will be calculated according to customer require -

Brand Name Attractivechina Dimension(L*W*H) Customized Design Place of Origin Guangdong, China Advantage High-efficiency,environmental-protection Production Capacity Depending on customer needs After-sales Service Provided Engineers available to service machinery overseas Product certificate EAC/CE,ISO14001,ISO45001,1SO9001

Related Products