about Attractivechina

Coating Line System Integrator

Guangdong Chuangzhi Intelligent Equipment Co., Ltd. was established in 2005 with a registered capital of 60.8 million CNY. It is a national high-tech enterprise integrating pre-sales whole plant planning, independent research and development, design, manufacturing, installation, commissioning and after-sales service.

Attractivechina has 30 years of experience in overall solutions for coating production lines. It mainly provides various types of customized automated coating production lines, coating equipment, environmental protection equipment and other whole-plant solutions for customers in various industries such as auto parts, rail transit, furniture, musical instruments, cookware, home appliances, metallic, aerospace, and industrial equipment.

Success stories 2000+

Technical precipitation (item)

Paint production experience

Floor area (M²)

Enterprise establishment

Registered capital

INDUSTRY SOLUTIONS

Attractivechina Always Provide You With The

Correct Coating Equipment Solution

>>>>>>>

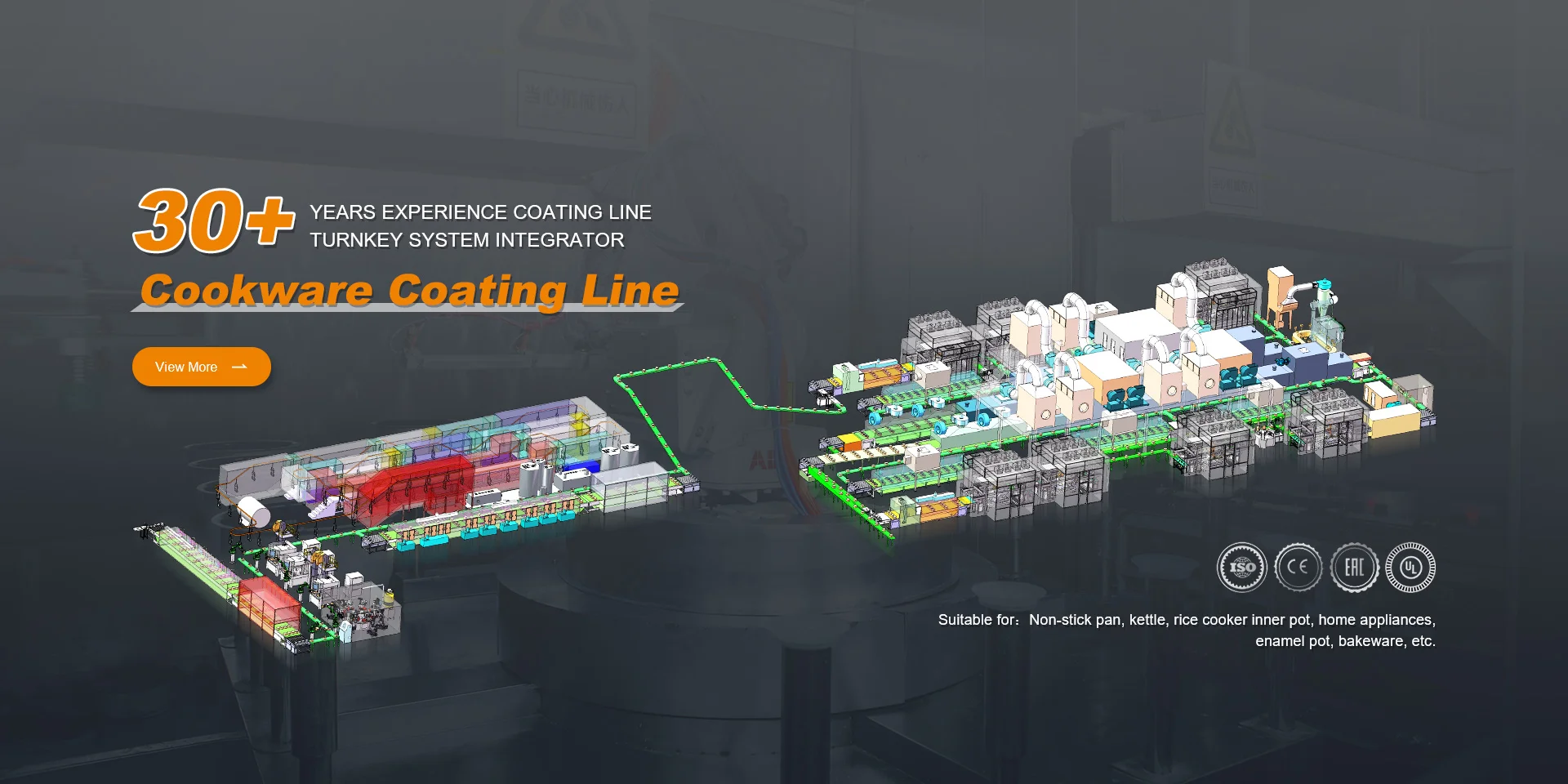

Cookware Coating Line

Cookware Coating Line

Wood Coating Line

Wood Coating Line

Auto Parts Coating Line

Auto Parts Coating Line

Metallic Coating Line

Metallic Coating Line

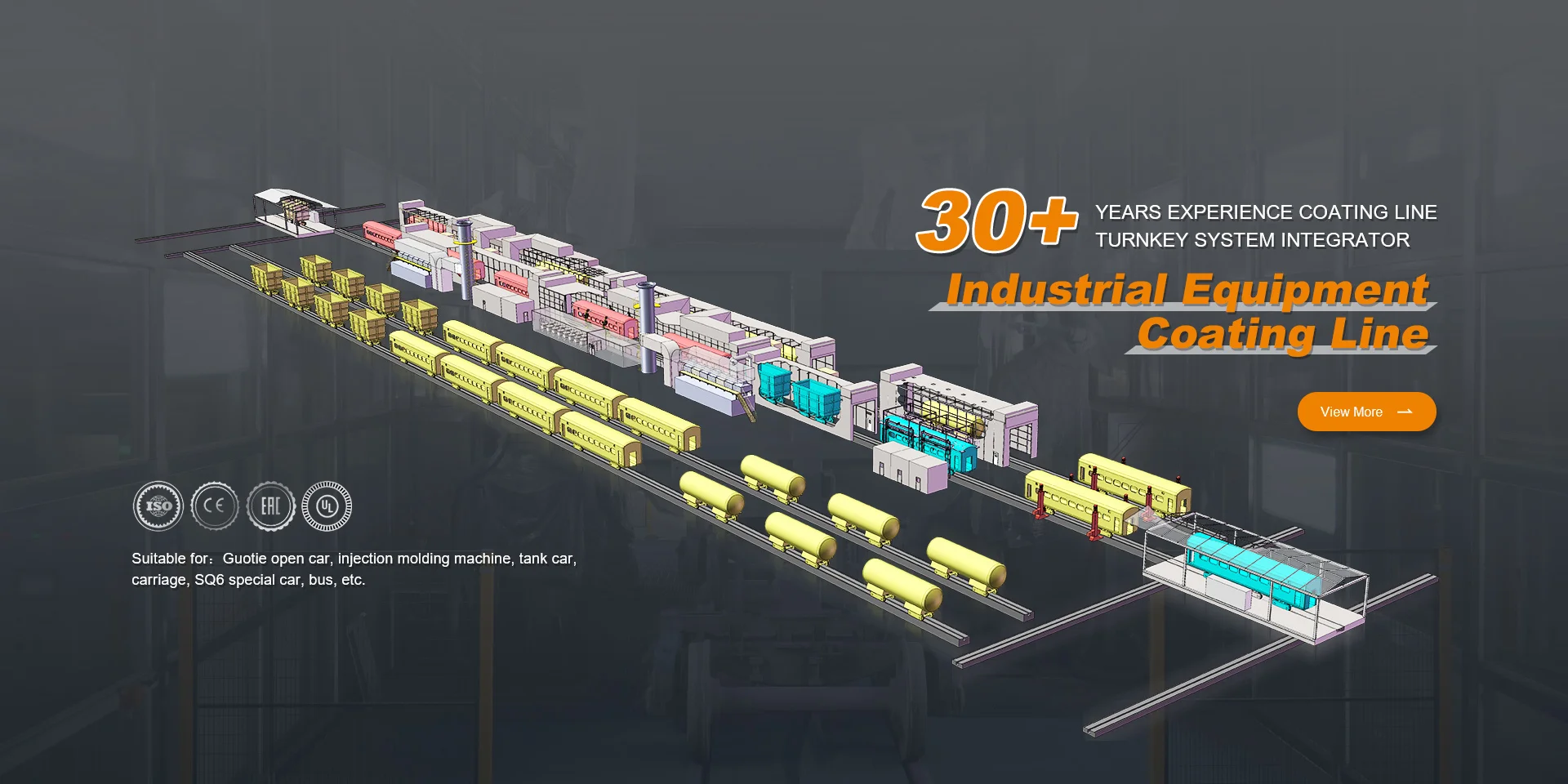

Industrial Equipment Coating Line

Industrial Equipment Coating Line

Cookware Coating Line

Adopt programmable digital control system, robot spraying, flexible production, and realize unmanned intelligent manufacturing process; The whole line has compact structure, high degree of automation and real-time control production.

Wood Coating Line

Realize flexible continuous spraying production, applicable to the plane and side of various customized furniture, musical instruments and other products, and the continuous operation of multi-layer coating; The transportation process design such as power and free type conveyor and skid type to effectively reduce the equipment’s foot print.

Auto Parts Coating Line

Visual production with MES system, and class 10000 constant temperature and humidity dust-free coating workshop. The overall surface cleanliness of the product is high, the coating adhesion is strong, and the one-time pass rate of the products can reach more than 95%.

Metallic Coating Line

Realize real-time production monitoring, adopt programmed digital control system, and the operation speed is adjustable; Excellent production efficiency, combined with multiple pre-treatment processes to ensure the products can meet the quality requirement after powder or wet paint coating.

Industrial Equipment Coating Line

Realize automatic color changing system, and cooperate with fully automatic heavy floor conveyor; Reduce the influence of human factors on its production efficiency and quality.

our cases

Attractivechina Focus On Customer Satisfaction

Our strengths

Why Choose Attractivechina?

Modernization Of Production Mode

The entire line equipment has a high degree of automation, advanced process flow and technology, which can achieve cost reduction and efficiency improvement.

Humanized Management Philosophy

The main focus is on employee skill growth, and regular safety product technical training is organized for employees.

On time delivery of equipment

Introduced digital intelligent project management platforms such as SRM and PMS, integrated the entire project installation process, and improved work efficiency.

Intelligent device functionality

Provide customized solutions according to customers' needs, and provide customers with intelligent and digital services based on industrial Internet technology.

Equipment Performance Stabilization

The equipment mainly focuses on automated and flexible production, using MES real-time monitoring and visual production progress management.

Quality assurance standardization

Implement comprehensive quality control, strictly control raw material procurement, product monitoring, etc.

Stabilizing Procurement Channels

Select high-quality suppliers and directly pick up goods from the manufacturer, ensuring quality, delivery time, and price.

Professional And Timely Service

Efficient service always on standby, quick response to provide you with thoughtful service, allowing you to achieve twice the result with half the effort.

Business scope

Attractivechina Products Are Exported To Multiple Countries

Sold to countries and regions such as Thailand, Vietnam, India, Indonesia, Iran, Bangladesh, Singapore, Russia, Pakistan, the United States, and Mexico.

our information

Read The Latest News About Attractivechina

Integrated Coating Solutions for Complex Production Needs

Feb 27,2026

How to Ensure Uniform Coating Thickness on Complex-Shaped Parts in a Production Line?

Mar 06,2026

Cookware

Cookware

Furniture

Furniture

Automobile

Automobile

Metallic

Metallic

Industrial Equipment

Industrial Equipment