25

2024-09

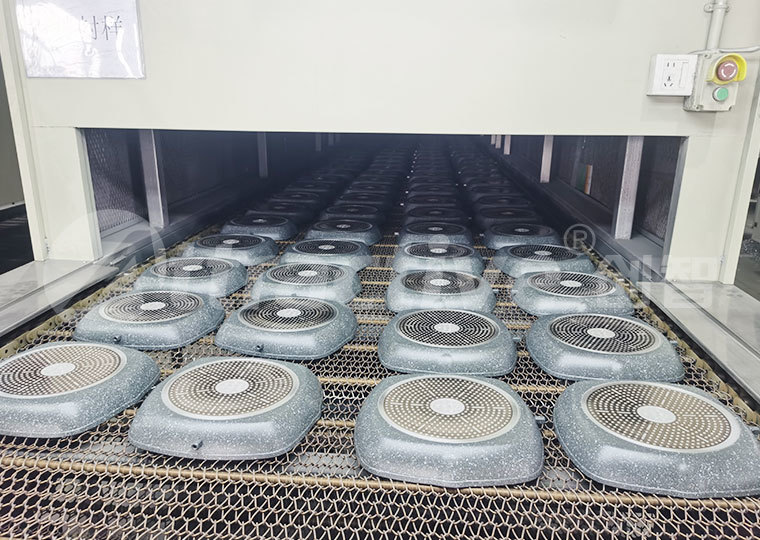

Green Pretreatment Cleaning Line: the successful cooperation between Chuangzhi Coating and Ningbo Kitchenware Company

Author:

Chuangzhi Coating

In today's society, environmental protection and energy conservation have become the core elements of corporate development. As an industry leader, a kitchenware company in Ningbo is committed to improving product quality while promoting the greening of the production process. Therefore, the company joined hands with the Chuangzhi Coating team to create an efficient, environmentally friendly and energy-saving frying pan pretreatment cleaning line, setting a new benchmark for the industry.

1. Zero emission of waste gas, promoting a new trend of green production

A major highlight of this pretreatment cleaning line is the realization of zero emission of waste gas. The Chuangzhi Coating team uses a patented product independently developed by itself, the pretreatment waste gas condensation and emission reduction device, which can effectively collect the waste gas generated during the cleaning process and convert it into harmless substances, avoiding the pollution of the environment by traditional cleaning lines. The introduction of this advanced equipment fully reflects Ningbo Kitchenware Company's firm commitment to environmental protection and sets an example for green production in the industry.

2. Stainless steel structure, durable and beautiful

The main body of the pretreatment cleaning line is made of high-quality stainless steel, which is not only corrosion-resistant and wear-resistant, ensuring the long-term stable operation of the equipment, but also its metallic luster and smooth lines add a beautiful landscape to the production site and show the professional image of the company.

3. Convenient maintenance, automatic monitoring system has advantages

The Chuangzhi coating team has equipped the pretreatment cleaning line with an advanced automatic monitoring and dosing system, which monitors the concentration and pH value of the cleaning fluid in real time and automatically adjusts the dosing amount. This not only ensures the cleaning effect, but also reduces the labor intensity of the operator. In addition, the design of each component is easy to disassemble and replace, which is convenient for daily maintenance and prolongs the service life of the equipment.

4. Water pump leakage prevention, filtration and cleaning double guarantee

In order to ensure the cleaning effect of the workpiece, our professional technical team customized the water pump design for the pretreatment cleaning line to effectively prevent the leakage of the cleaning fluid and ensure the safety and hygiene of the production site. Equipped with an efficient filtration system to thoroughly remove impurities and particles in the cleaning fluid to ensure the consistency and stability of the cleaning effect.

5. Heat pump dehumidification and drying system, energy saving and environmental protection

The Chuangzhi team integrated the heat pump dehumidification and drying system, electric auxiliary heating system and hot air circulation system in the pretreatment equipment to form an efficient and energy-saving drying process. The heat pump technology recycles and reuses the heat energy in the air, greatly reducing energy consumption. The electric auxiliary heating system is used in the initial heating stage to improve energy utilization efficiency. The hot air circulation system ensures uniform temperature distribution during the drying process and achieves rapid drying.

In summary, the frying pan pre-treatment cleaning line created by Chuangzhi Coating and Ningbo Kitchenware Company has improved production efficiency and product quality with its many advantages, and has made important contributions to the green development and sustainable development of the industry.