编号 :

Attractivechina2025081450

Furniture Painting Machine Wooden Paint Line UV Painting Machine

零售价

市场价

Technology at home and abroad

Quality assurance

Tailored

Original purchase

全国客户服务热线 7*24小时:

+86 758-6626158-8063

重量

库存

隐藏域元素占位

- Product Details

- Product Parameters

- Product Properties

-

The Furniture Painting Machine is designed specifically for the efficient and high-quality finishing of wooden furniture. With advanced spraying technology, this machine ensures an even and smooth application of paint, enhancing the aesthetic appeal of each piece. Its automated features reduce labor costs and improve production speed, allowing manufacturers to meet high demand with consistent results. The user-friendly interface makes it easy to adjust settings for different types of finishes, ensuring versatility for various furniture styles.

The Wood Paint Line is a coating solution for finishing wooden products, encompassing multiple stages from surface preparation to final coating. This line integrates advanced technologies to automate processes such as sanding, priming, and painting, ensuring a seamless workflow. The system is designed to optimize paint usage, reducing waste and enhancing environmental sustainability. With precise control over each stage, manufacturers can achieve consistent finishes across a variety of wood types and sizes. Its modular design allows for customization based on production needs, making it suitable for both small artisans and large manufacturers seeking efficiency and quality in their wood finishing processes.

The UV Painting Machine utilizes cutting-edge ultraviolet technology to cure paint instantly, offering significant advantages in speed and efficiency for wood finishing. This machine delivers a high-gloss, durable finish that is resistant to scratches and chemicals, making it ideal for high-end furniture and cabinetry. Additionally, the energy-efficient design of the UV Painting Machine minimizes environmental impact while providing exceptional results.

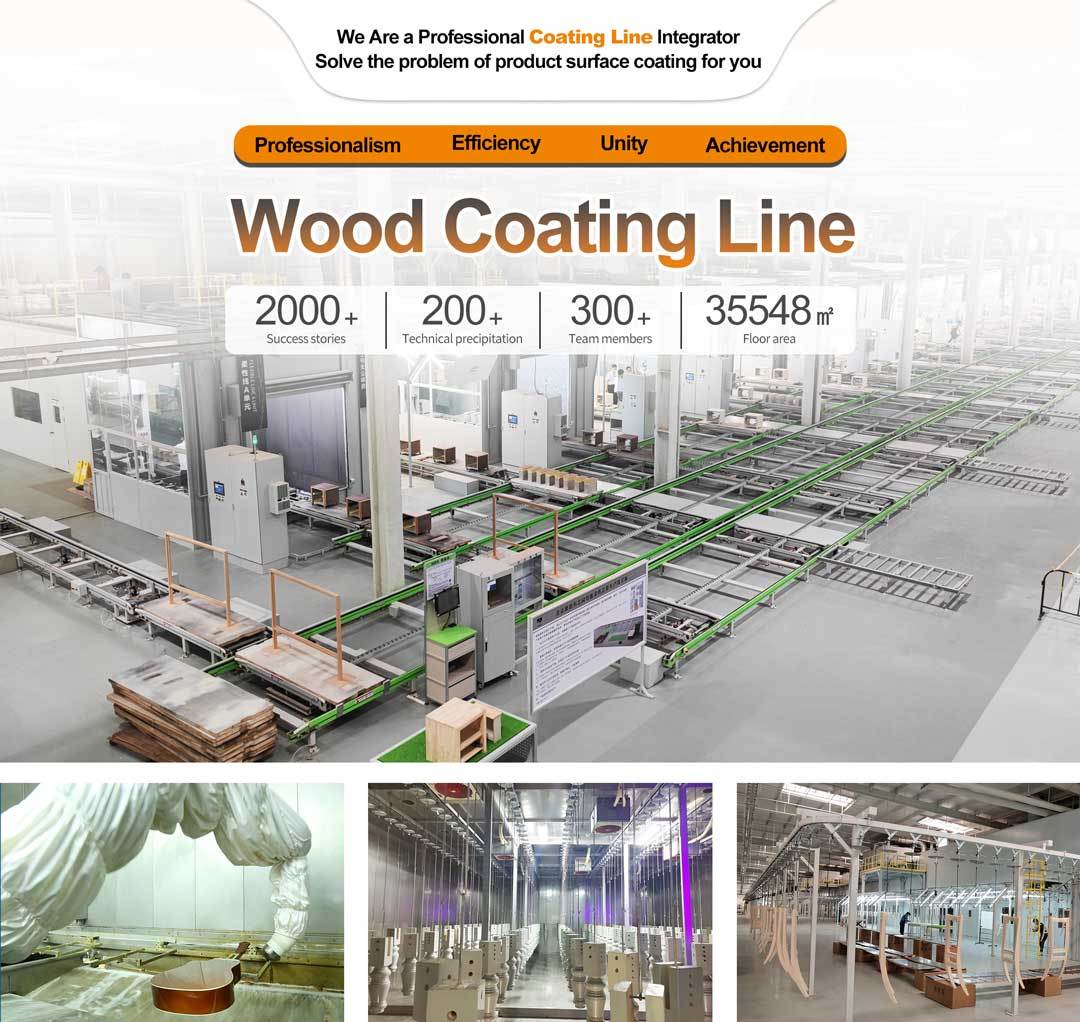

Wood Coating Line

1. With the good design of the whole spray line, convenient operation, beautiful appearance and strong accessibility.

2. The entire spraying line is running smoothly, the work of each station is simple, easy for inspection.

3. High degree of automation, saving a lot of labor.

4. The entire spray line with steady performance.

5. The spray line pump of the injection line adopts a specific liquid sludge pump, which is maintenance-free and no leakage.

6. The spraying injection line uses seven tons of tension transport chain, A3 steel material, quenching treatment, balance running, little abrasion.

7. The spraying room with good ventilation, the air supply and the exhaust are balanced, and the spray positions are fully automatic.

8. The workpiece rotation is uniform, multi-point spraying.

9. Automatic induction spraying to reduce paint loss.

10. All drying temperatures are automatically controlled and adjustable, with insulation effect.

11. Using computer touch screen control totally, each part of the point control separately.

12. The heating method is designed by the client's energy source, which is economic, safe and reliable, and easy to maintain, and guarantee the quality requirements of the workpiece.

13. The insulation layer changes the conventional rock wool insulation. All the low-temperature furnaces of our factory products are insulated with aluminum silicate cotton to ensure the temperature and save the invisible energy.

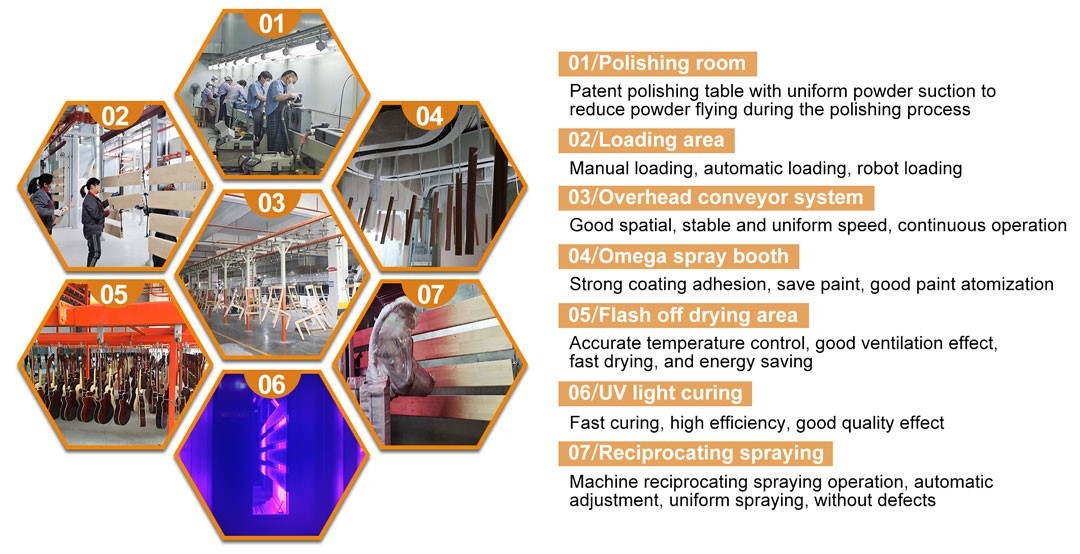

Technological Process

Wood Coating Line

Loading→Primer 1 spraying→Primer 2 spraying→Glue spraying→Wiping→Primer→Dry brush→Two coats of primer→Tint→Top-coat→Inspection area→Finished product drying→Unloading

-

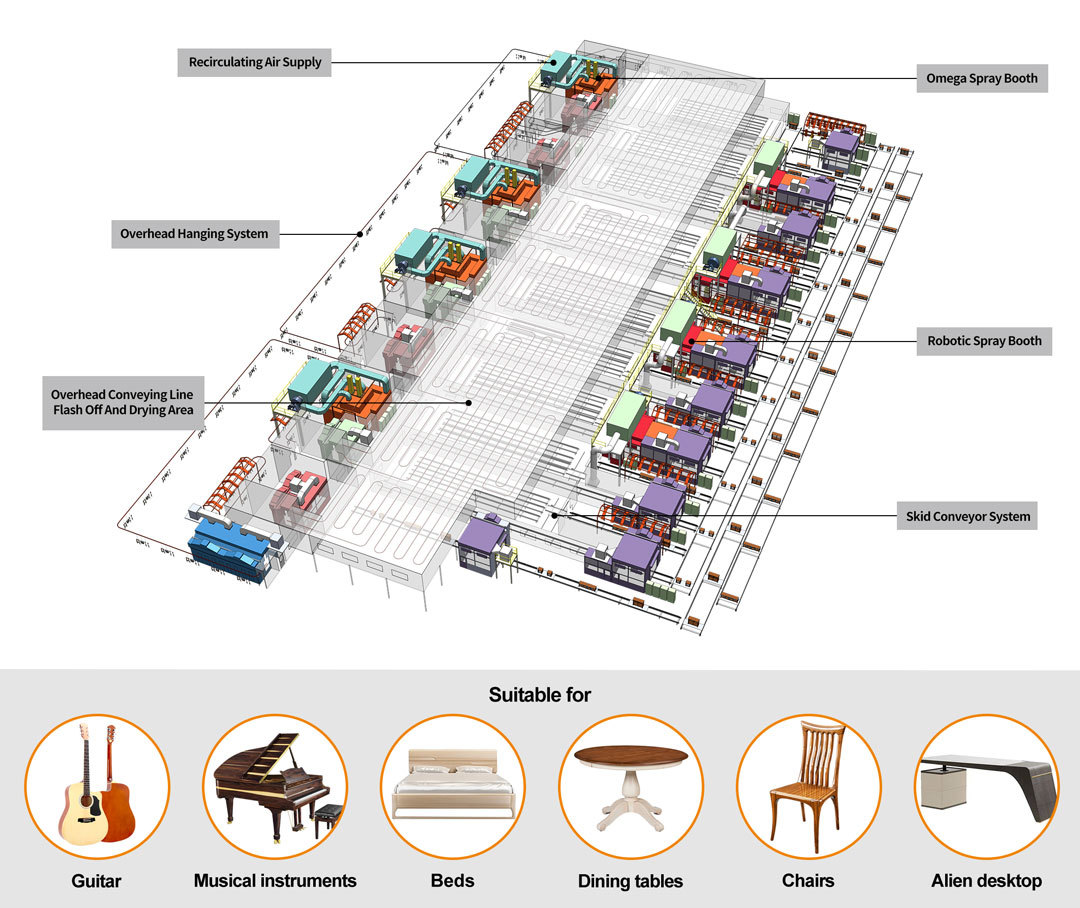

Workpiece: Guitar, musical instruments, beds, dining tables, chairs, alien desktop, etc. Workpiece material: Solid wood, medium fiber board, veneer particleboard Work system: 300 days/year; 20H/day; equipment utilization rate: 85% Spray booth temperature: 18~26°C Spray room humidity: 45~75%RH Spraying method: Artificial/Robotic Tool tray size: L2300 * W800 * H2200mm (reference) Production rhythm: 1.0min-4min/pry (depending on different workpieces) Workpiece weight: 300KG Power: 380V 3φ 50 Hz Compressed air: Pressure≥0.7MPa±5%(Gauge pressure)、oil<0.01mg/m³ 、solid <1.00mg/m³ 、dew point 0.6Mpa -20℃ Natural gas: Standard pressure is medium pressure 80kPa Tap water: Pressure≥1.5Kg/㎝2 Heating energy: Electricity, natural gas Note: Above data for reference only, the actual data will be calculated according to customer require -

Brand Name Attractivechina Dimension(L*W*H) Customized Design Place of Origin Guangdong, China Advantage High-efficiency,environmental-protection Production Capacity Depending on customer needs After-sales Service Provided Engineers available to service machinery overseas Product certificate EAC/CE,ISO14001,ISO45001,1SO9001

Related Products