编号 :

Attractivechina2025081427

Large Carriage Industrial Coating Line Painting Spray Machine Automatic Painting Equipment Manufacturers

零售价

市场价

Technology at home and abroad

Quality assurance

Tailored

Original purchase

SEO:

全国客户服务热线 7*24小时:

+86 758-6626158-8063

重量

库存

隐藏域元素占位

- Product Details

- Product Parameters

- Product Properties

-

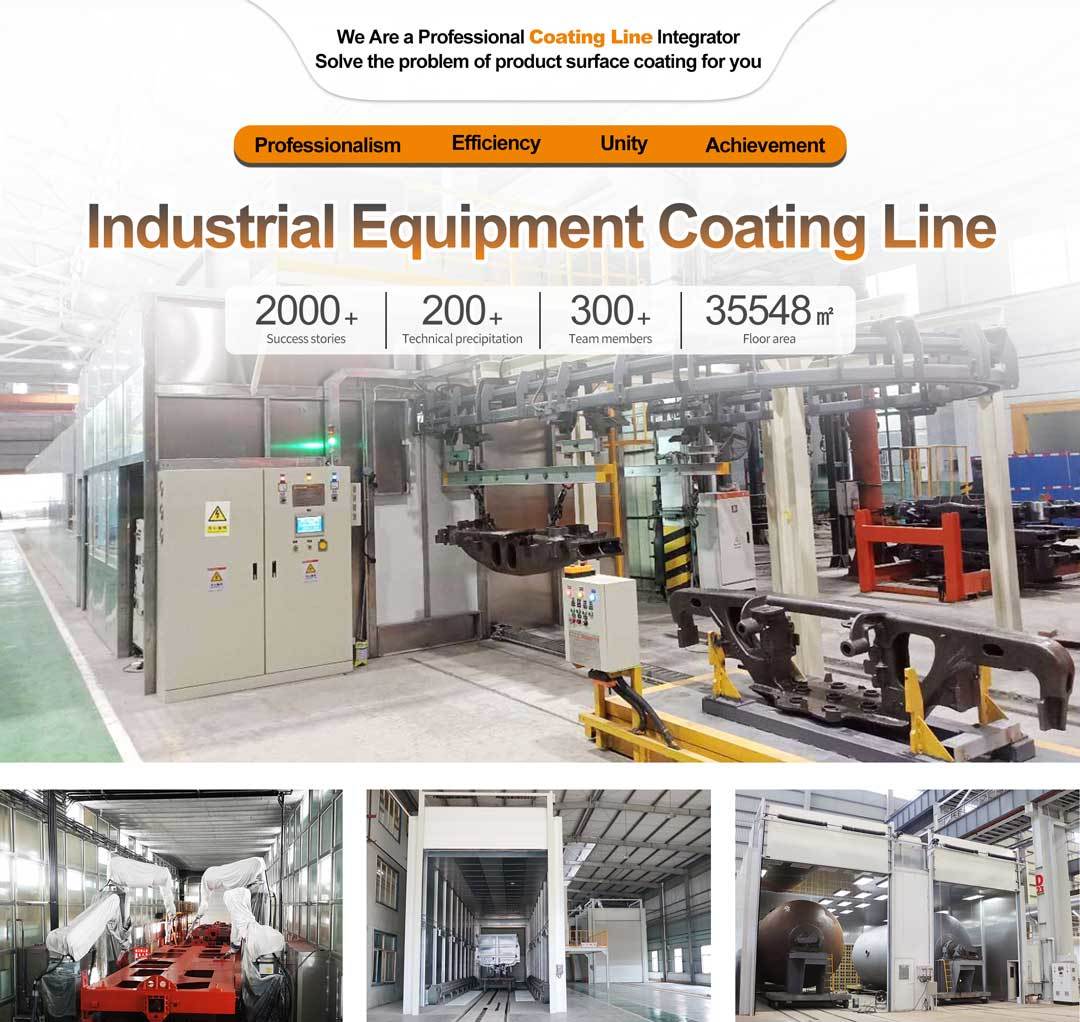

Industrial Equipment Coating Line

Industrial Automation Coating Line

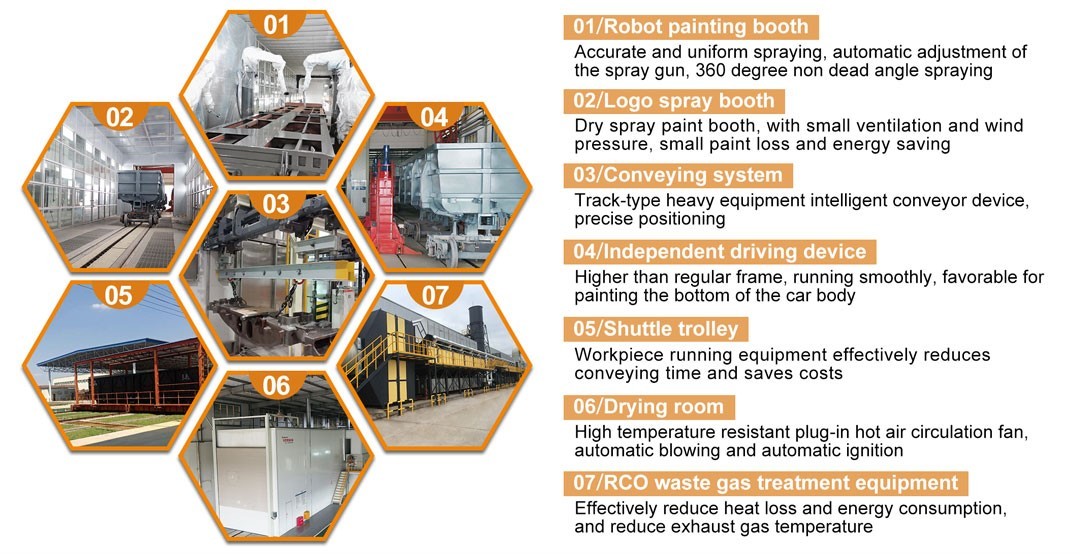

Industrial Automation Coating Line is an important solution for improving production efficiency and coating quality in modern manufacturing. The system realizes integrated operation from pretreatment, spraying to drying through highly integrated automation technology. Using robot arms and intelligent control systems, the spraying process can be precisely controlled to ensure uniform coating and consistent thickness. At the same time, the production line reduces the need for manual operation, reduces the possibility of human error, and improves safety. Suitable for large-scale production, it can be flexibly adjusted to meet the coating requirements of different products and materials, which is the key to improving the competitiveness of enterprises.Painting Spray Machine

The painting spray machine is an efficient and professional coating equipment widely used in industrial production. It atomizes the paint through the nozzle to evenly cover the surface of the workpiece. The design of the spray machine usually takes into account ergonomics and is easy for the operator to use. Many modern spray painting machines are equipped with digital control systems, allowing users to accurately adjust the spray pressure, flow rate and spray width to adapt to different types of coatings and workpiece shapes. This flexibility makes the spray machine not only suitable for large-scale production, but also capable of small-scale customization, and is widely used in industries such as automobiles, furniture, and hardware.Painting Equipment Manufacturers

As a coating equipment manufacturer, we play a vital role in modern industry. We specialize in the design and production of various coating equipment, such as pre-treatment equipment, drying equipment and environmental protection equipment. Our goal is to improve the performance and reliability of equipment, while constantly innovating to adapt to changes in market demand. We work closely with customers to provide customized solutions based on their specific production needs. By introducing advanced technologies and optimizing production processes, we help companies improve production efficiency, reduce costs, and enhance product quality to promote the development of the entire industry. We are committed to providing customers with the highest quality coating equipment to ensure that they stay ahead in the competitive market.

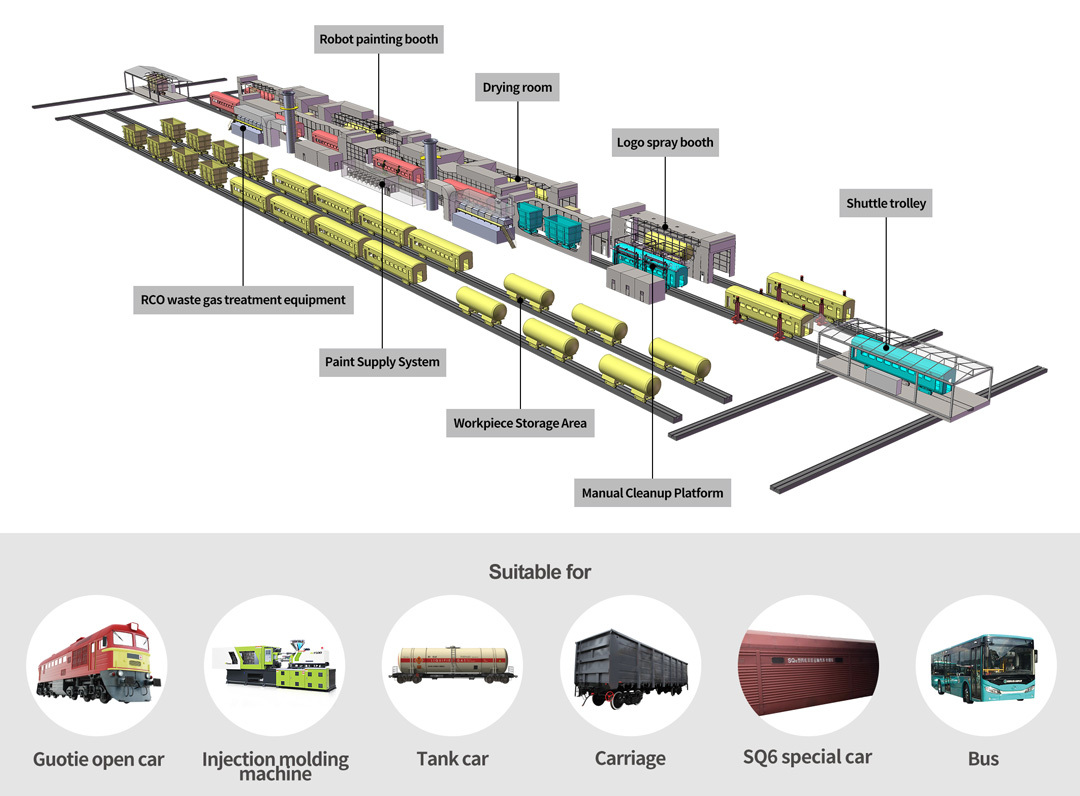

Technological Process

Industrial Equipment Coating Line

Loading→Replacing the frame→Rust removal, polishing and dust blowing→Preheating and dehumidification→Primer automatic spraying booth→Primer drying booth→Cooling→Preheating→Top-coat spraying→Top-coat drying→Cooling→Logo spraying→Replacing the frame→Unloading

-

Workpiece: Guotie open car, injection molding machine, tank car, carriage, SQ6 special car, bus, etc. Workpiece material: Iron, aluminum Work system: 300 days/year; 15H/day; equipment utilization rate: 85% Spray booth temperature: 15~32°C Spray room humidity: 55~75%RH Spraying method: Robot + manual powder spraying Main parameters of applicable vehicle models: 1. Vehicle length: 10000-26100mm;2. Vehicle width 2400-340mm;3. The maximum height of the vehicle is 4800mm (based on horizontal ground);4. Vehicle spacing of 5000-20800mm;5. The maximum weight of the vehicle body is 38000kg Fixture workpiece pitch: 38100mm,33020mm, 29210mm, 20320mm Conveyor speed: 1200mm/min (1-4.5m/min Adjustable) Length of conveyor belt: About 970M Plant size: 258m(L)*20m(W)*11m(H) Power: 380V 3φ 50 Hz Compressed air: Pressure≥0.7MPa±5% oil<0.01mg/m³ solid <1.00mg/m³ dew point 0.6Mpa -20℃ Natural gas: Standard pressure is medium pressure 80kPa Tap water: Pressure≥1.5Kg/㎝2 Heating energy: Electricity, natural gas Note: Above data for reference only, the actual data will be calculated according to customer require -

Brand Name Attractivechina Dimension(L*W*H) Customized Design Place of Origin Guangdong, China Advantage High-efficiency,environmental-protection Production Capacity Depending on customer needs After-sales Service Provided Engineers available to service machinery overseas Product certificate EAC/CE,ISO14001,ISO45001,1SO9001

Related Products