编号 :

Attractivechina2025081405

Auto Parts Coating Equipment Automatic Spray Painting Machine Powder Coating Line

零售价

市场价

Technology at home and abroad

Quality assurance

Tailored

Original purchase

SEO:

全国客户服务热线 7*24小时:

+86 758-6626158-8063

重量

库存

隐藏域元素占位

- Product Details

- Product Parameters

- Product Properties

-

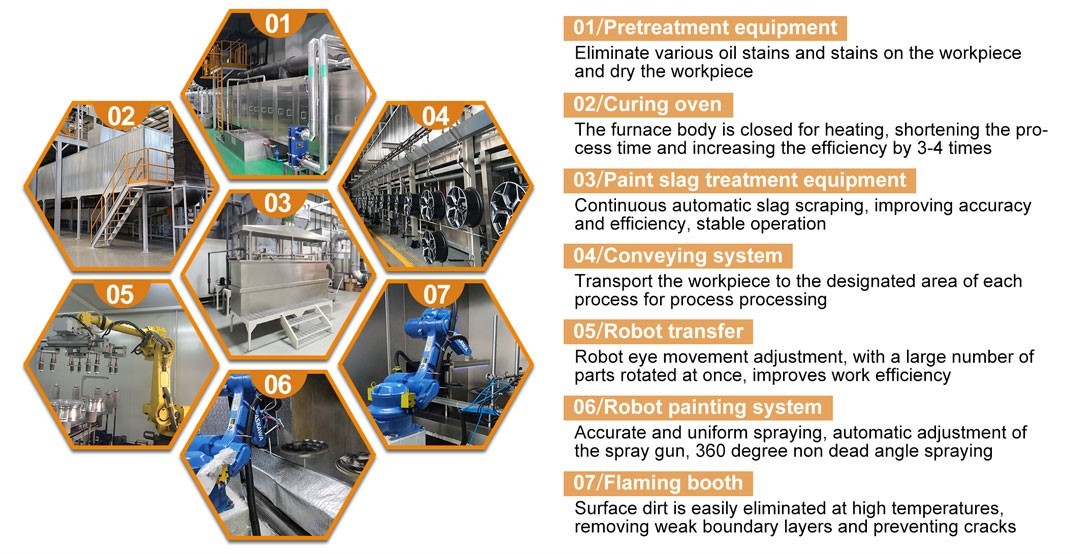

Attractivechina Auto Parts Coating Line is designed for efficient, uniform and environmentally friendly coating of automotive parts. The equipment integrates advanced automation control technology and can automatically complete the whole series of coating processes such as loading, spraying, drying and unloading, greatly improving production efficiency and product quality. Through the precise spray gun system and powder recovery system, it ensures that each layer of coating is uniform and delicate, while reducing material waste and environmental pollution.

Product advantages:

1. Efficient automation: fully automated operation, reducing manual intervention, significantly improving production efficiency and reducing labor costs. From parts loading to finished product unloading, no manual supervision is required throughout the process, achieving 24-hour uninterrupted production.

2. Environmental protection and energy saving: using powder coating, compared with traditional solvent-based coating, VOCs (volatile organic compounds) emissions are greatly reduced, in line with national environmental protection standards. At the same time, efficient energy management system and waste heat recovery technology further reduce energy consumption and reduce carbon emissions.

3. Excellent coating quality: precise spray gun control system and powder recovery and reuse technology ensure uniform, smooth coating, no defects such as sagging. High adhesion and corrosion resistance, extending product life.

4. Flexible customization: According to customer needs, customized solutions for the entire production line can be provided. Whether it is a small workshop or a large factory, the most suitable configuration solution can be found.

5. Intelligent monitoring and maintenance: The integrated intelligent monitoring system monitors the equipment operation status and coating quality in real time, and warns of potential failures in advance. Convenient maintenance interface and modular design make equipment maintenance simpler and faster.

Auto Parts Coating Line

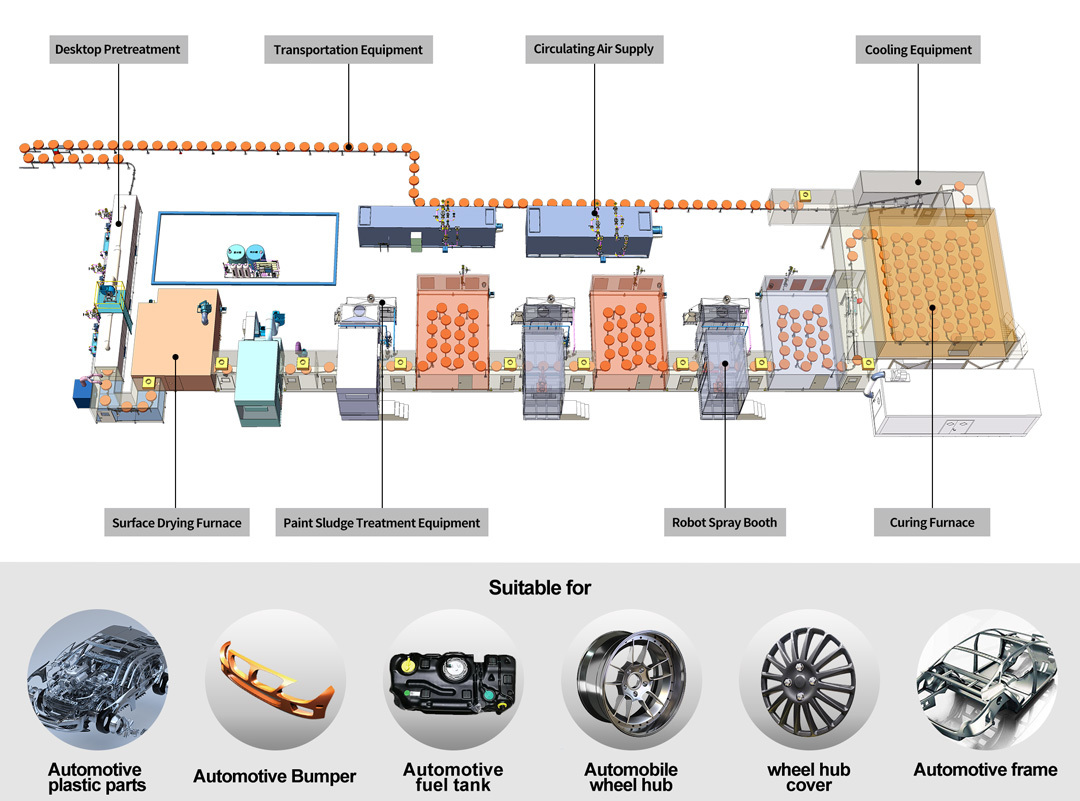

The automotive coating line integrates functions such as automatic spraying, drying, curing, and conveying, which can adapt to various sizes and types of auto parts. Its intelligent control system can accurately adjust according to product size and color requirements, ensuring uniform and consistent coating effects. At the same time, the system also has automatic detection and correction functions, which can timely detect and repair coating defects, and improve product quality standards.

Technological Process

Auto Parts Coating Line

Loading→Degreasing→Rinsing→Pure water washing→Water blowing→Moisture drying→Cooling→Flame treatment→Automatic electrostatic dust removal→Primer spraying→Surface drying→Mid-paint spraying→Surface drying→Top-coat spraying→Surface drying→Curing→Cooling→Unloading→Inspection and packaging

-

Workpiece: Automotive bumper, wheel hub, wheel hub cover, automotive fuel tank, frame, etc Workpiece material: ABS、PS、PPE、PA Work system: 300 days/year; 20H/day; equipment utilization rate: 85% Spray booth temperature: 25±3°C Spray room humidity: 65±5%RH Spraying method: Robot Maximum installation size of round Fixture: φ600×H150mm Fixture workpiece pitch: 300, 600, 900mm Conveyor speed: 500mm/min (1-3m/min Adjustable) Length of conveyor belt: About 255M Plant size: 80m(L)*30m(W)*11m(H) Power: 380V 3φ 50 Hz Compressed air: Pressure≥0.7MPa±5% oil<0.01mg/m³ solid <1.00mg/m³ dew point 0.6Mpa -20℃ Natural gas: Standard pressure is medium pressure 80kPa Tap water: Pressure≥1.5Kg/㎝2 Heating energy: Electricity, natural gas Note: Above data for reference only, the actual data will be calculated according to customer require -

Brand Name Attractivechina Dimension(L*W*H) Customized Design Place of Origin Guangdong, China Advantage High-efficiency,environmental-protection Production Capacity Depending on customer needs After-sales Service Provided Engineers available to service machinery overseas Product certificate EAC/CE,ISO14001,ISO45001,1SO9001

Related Products