编号 :

Attractivechina2025081416

Sandblasting Equipment Curing Furnace Powder Coating Production Line For Manufacturing Cookware

零售价

市场价

Technology at home and abroad

Quality assurance

Tailored

Original purchase

SEO:

全国客户服务热线 7*24小时:

+86 758-6626158-8063

重量

库存

隐藏域元素占位

- Product Details

- Product Parameters

- Product Properties

-

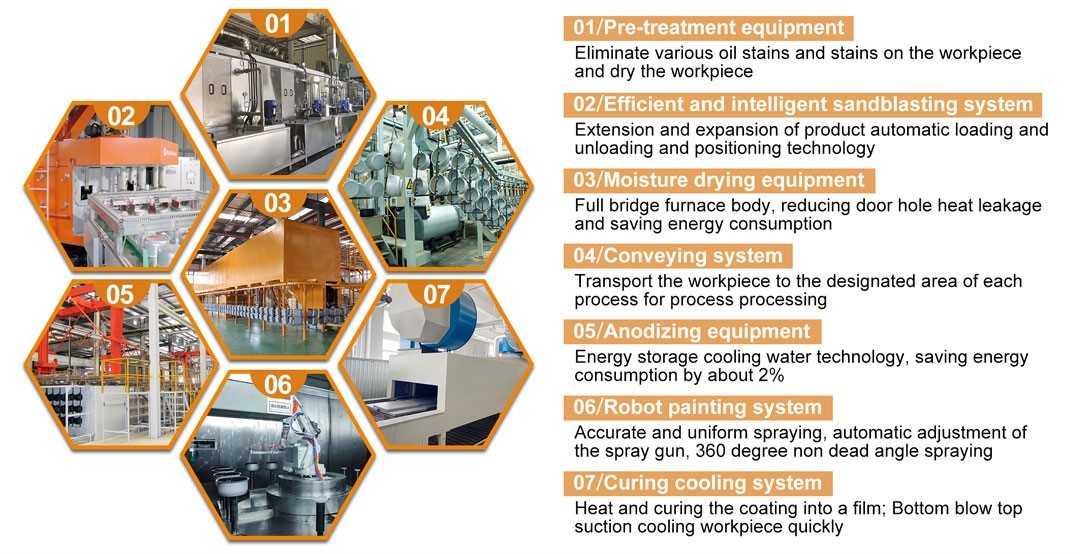

The powder coating production line is a comprehensive system for the efficient manufacturing of powder coated products. It encompasses various stages such as surface treatment, powder application, and curing. This line ensures high-quality coatings with excellent adhesion and durability.

In the powder coating production line, precise control of parameters is crucial. From powder flow to curing temperature, everything is monitored and adjusted to achieve optimal results. The line is capable of handling a large volume of products with consistent quality.

The powder coating production line is widely utilized in different industries for its numerous benefits. It offers a decorative and protective finish, is environmentally friendly, and provides cost-effective solutions. The continuous innovation in this line keeps it at the forefront of coating technologies.

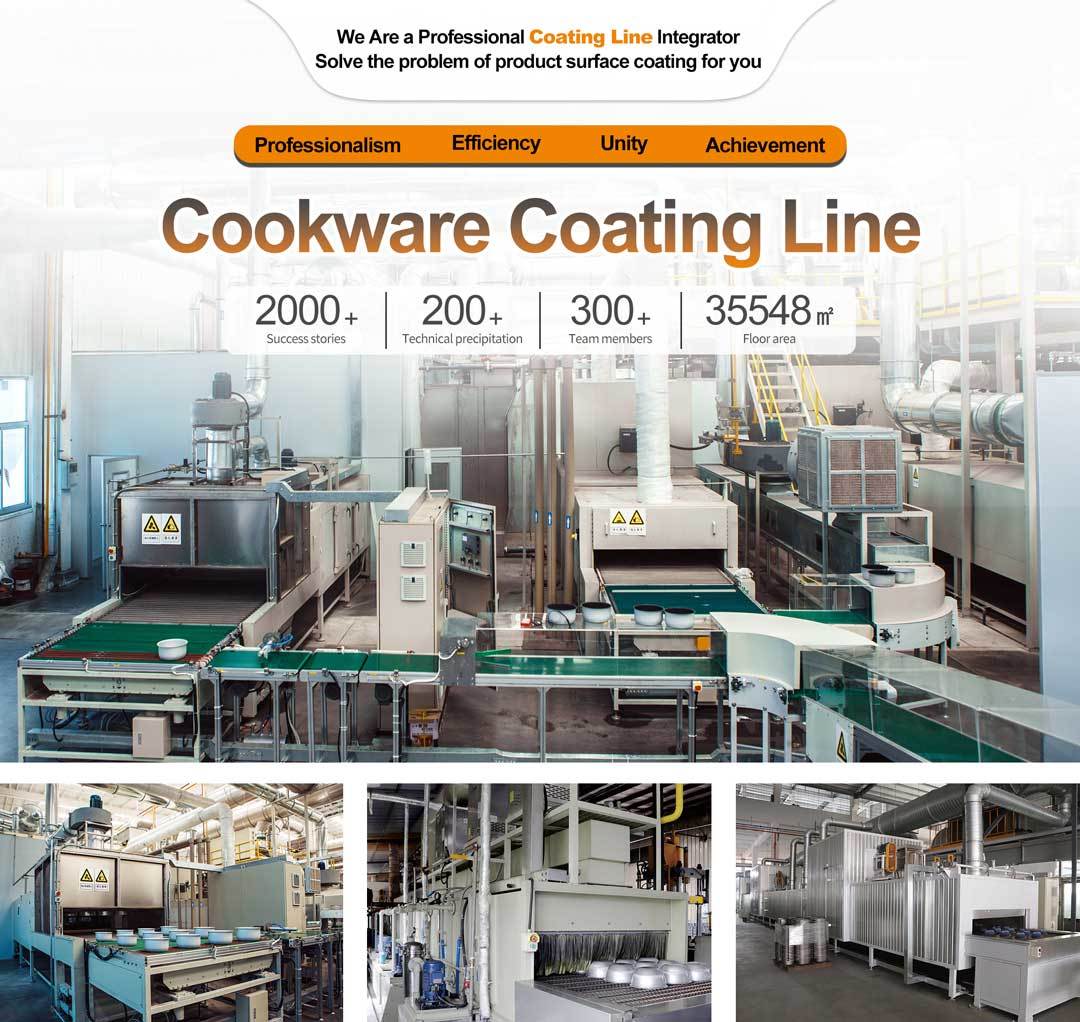

Cookware Coating Line

This is an advanced cookware coating production line that provides efficient and precise coating solutions to cookware manufacturers. Advanced automation technology and precision coating equipment are used to ensure that each cookware gets an even and durable coating.

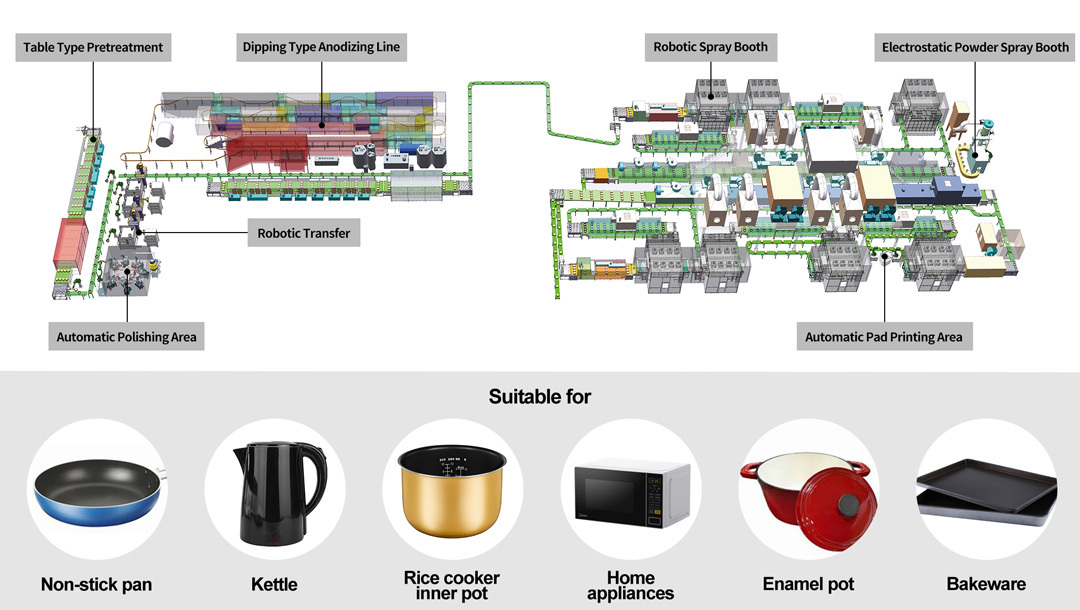

Technological Process

Pretreatment production line

Loading→Hot rinsing→Pre-degreasing→Degreasing→Rinsing→Direct spraying by pure water→Blow water→Drying→Cooling→Sand blasting→Rinsing desanding→Alkali corrosion→Rinsing→Neutralization→Rinsing→DI rinsing→Blow water→Drying→Cooling→Transfer

Ordinary anodizing technology

Loading→Pre-degreasing→Degreasing→Rinsing→Alkali corrosion→Rinsing→Neutralization→Rinsing→Direct spraying by pure water→Oxidation→Rinsing→Sealing→DI rinsing→Drying→Cooling→Unloading

Inner pot coating line process

Loading→Automatic dedusting→Pre-heating→Primer spraying→Primer drying→Cooling→Inner pot→Water level markpad printing→Pre-heating→Powder spraying→High temperature curing→Cooling→Unloading

Outer pot coating line process

Loading→Automatic dedusting→Pre-heating→Primer spraying→Primer drying→Cooling→Outer pot→Top-coat spraying→Top-coat drying→Cooling→High temperature curing→Cooling→Unloading

-

Workpiece: Non-stick pan,kettle,rice cooker inner pot,home appliances,enamel pot,bakeware, etc. Workpiece material: Aluminum alloy, composite material (stainless steel, aluminum alloy, copper, etc.) Work system: 300 days/year; 20H/day; equipment utilization rate: 85% Spray booth temperature: 18~26°C Spray room humidity: 45~75%RH Spraying method: Fixed gun/robot Workpiece size: Ф130~300 mm*160H Production output: 800 pieces/hour Power: 380V 3φ 50 Hz Compressed air: Pressure≥0.7MPa±5% oil<0.01mg/m³ solid <1.00mg/m³ dew point 0.6Mpa -20℃ Natural gas: Standard pressure is medium pressure 80kPa Tap water: Pressure≥1.5Kg/㎝2 Heating energy: Electricity, natural gas Note: Above data for reference only, the actual data will be calculated according to customer require -

Brand Name Attractivechina Dimension(L*W*H) Customized Design Place of Origin Guangdong, China Advantage High-efficiency,environmental-protection Production Capacity Depending on customer needs After-sales Service Provided Engineers available to service machinery overseas Product certificate EAC/CE,ISO14001,ISO45001,1SO9001

Related Products