编号 :

Attractivechina2025080515

Steel Cabinet Automatic Electrostatic Powder Metal Coating Line Manufacturers

零售价

市场价

Technology at home and abroad

Quality assurance

Tailored

Original purchase

SEO:

全国客户服务热线 7*24小时:

+86 758-6626158-8063

重量

库存

隐藏域元素占位

- Product Details

- Product Parameters

- Product Properties

-

Metal Coating Line

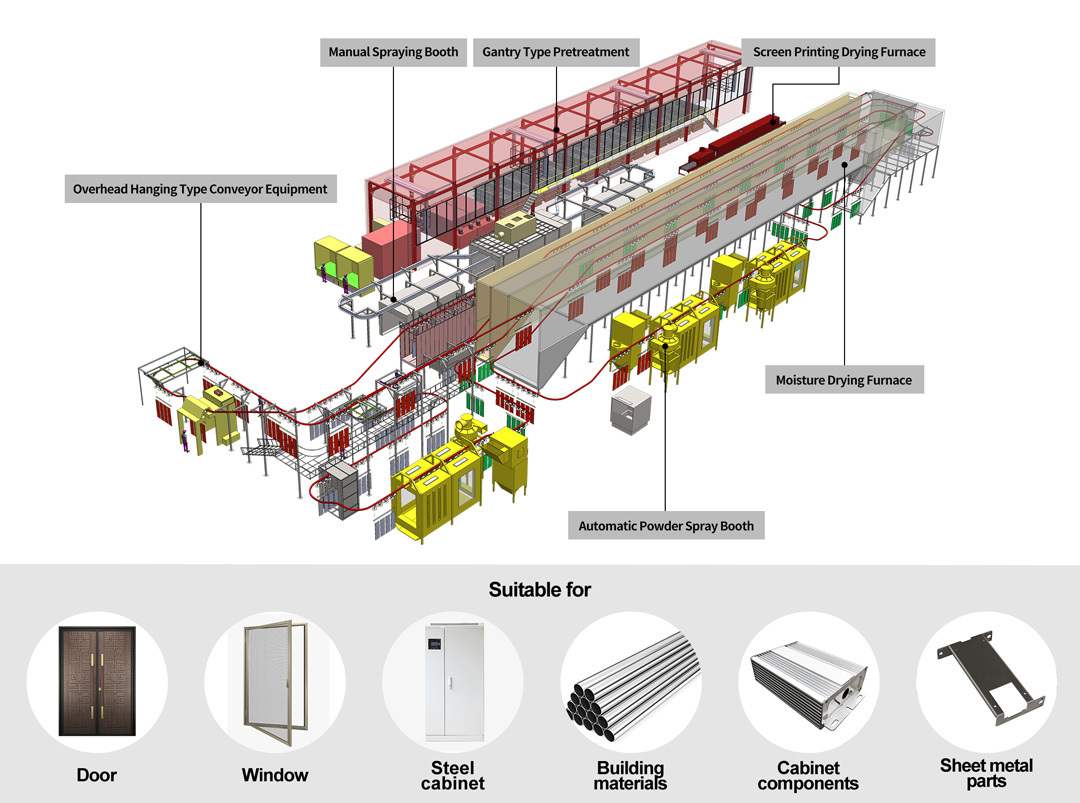

Steel Cabinet Automatic Spraying Line

This automatic spraying line is tailor-made for steel cabinets and features a highly automated process. Using advanced spraying technology, spraying parameters can be flexibly adjusted according to the needs of different parts of the cabinet to ensure a uniform and delicate coating, effectively improving the appearance, texture and anti-corrosion performance of steel cabinets.Electrostatic Powder Coating Line

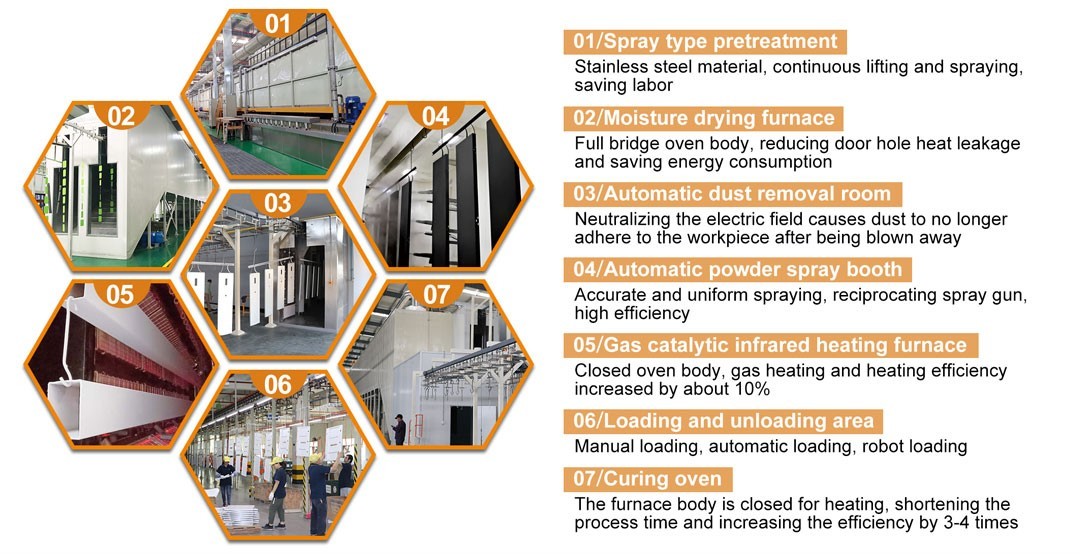

The electrostatic powder coating line uses the principle of electrostatic adsorption to make the powder coating evenly adhere to the surface of the workpiece. It has significant advantages. It can not only achieve an environmentally friendly and pollution-free coating process, but also ensure the uniformity and firmness of powder coverage by accurately controlling parameters such as electrostatic field strength. It is widely used in various metal products and can greatly improve the corrosion resistance and aesthetics of the product.Coating Line Manufacturers

Coating line manufacturers are the core force in the coating industry. With our profound technical accumulation and professional team, we focus on R&D, design and production of various high-quality coating lines. From understanding customer needs to creating customized solutions, to strict quality control and complete after-sales support, we ensure that we provide customers with coating line equipment that is reliable, efficient and can meet different production requirements.

Technological Process

-

Workpiece: Door, window, steel cabinet, building materials, cabinet components, sheet metal parts etc. Workpiece material: Iron, galvanized Work system: 300 days/year; 22H/day; equipment utilization rate: 85% Spraying method: Robot + manual powder spraying + reciprocating machine Maximum workpiece size of suspension line: 3000mm(L)x1000mm(W)x1800mm(H) 1mm/Hang Suspension line conveying method: 250 type double guide roller conveyor chain Chain pitch of suspension line: 250mm Hanging line workpiece pitch: 3500mm Hanging wire hanging method: Double point hanging, single point lifting weight 50kg Maximum workpiece production capacity : 68 pieces/H, 1496 pieces/day, 44.88 × 8500 pieces/year Conveyor speed: 4000mm/min(2000-5000mm/min Adjustable) Length of conveyor belt: About 363M Net height of factory building: 13m(H) Power: 380V 3φ 50 Hz Compressed air: Pressure≥0.7MPa±5% oil<0.01mg/m³ solid <1.00mg/m³ dew point 0.6Mpa -20℃ Natural gas: Standard pressure is medium pressure 80kPa Tap water: Pressure≥1.5Kg/㎝2 Heating energy: Electricity, natural gas Note: Above data for reference only, the actual data will be calculated according to customer require -

Brand Name Attractivechina Dimension(L*W*H) Customized Design Place of Origin Guangdong, China Advantage High-efficiency,environmental-protection Production Capacity Depending on customer needs After-sales Service Provided Engineers available to service machinery overseas Product certificate EAC/CE,ISO14001,ISO45001,1SO9001

Related Products