Related News

23

2025

-

07

Top 5 Challenges in Automotive Paint Shops and How to Overcome Them

Author:

Chuangzhi Coating

In the modern automobile manufacturing process, the paint shop plays a crucial role. It not only affects the exterior quality of the vehicle but also directly relates to the product's corrosion resistance, service life, and consumer satisfaction. However, with intensifying market competition and consumers' escalating quality requirements, automotive paint shops face numerous challenges. This article will delve into the top five challenges faced by automotive paint shops and propose corresponding solutions, aiming to provide valuable insights for paint line equipment manufacturers and automakers.

I. Challenge 1: Unstable Paint Quality

Unstable paint quality is the primary challenge faced by automotive paint shops. This may result from unreasonable paint formulations, fluctuations in painting process parameters, inadequate equipment precision, or varying skill levels among operators. Unstable paint quality not only impacts the aesthetic appeal of the vehicle but may also reduce its corrosion resistance, thereby shortening its service life.

Solutions:

II. Challenge 2: Low Production Efficiency

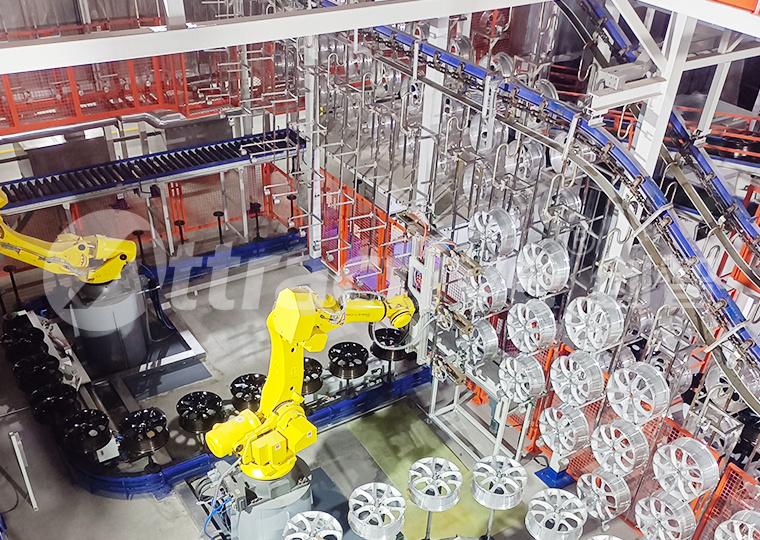

The production efficiency of automotive paint shops directly affects the production cycle and manufacturing costs of vehicles. However, due to complex painting processes, frequent equipment maintenance, and unreasonable production line layouts, many paint shops struggle with low production efficiency.

Solutions:

III. Challenge 3: Increasing Environmental Pressures

With increasingly stringent environmental regulations and consumers' heightened awareness of environmental protection, automotive paint shops face growing environmental pressures. Issues such as volatile organic compound (VOC) emissions and wastewater treatment have become bottlenecks restricting the development of paint shops.

Solutions:

IV. Challenge 4: Difficult Cost Control

Cost control in automotive paint shops involves multiple aspects such as paints, equipment, and labor. In a highly competitive market environment, how to effectively control painting costs and improve product competitiveness has become an important issue for paint shops.

Solutions:

V. Challenge 5: Insufficient Technological Innovation

With the rapid development of the automotive industry and diversifying consumer demands, automotive painting technology is constantly being updated and upgraded. However, some paint shops suffer from insufficient technological innovation, leading to outdated painting technology that cannot meet market demands.

Solutions:

2. Strengthen industry-university-research cooperation: Establish cooperative relations with universities, scientific research institutions, etc., and jointly carry out research and development of coating technology.

3. Pay attention to industry dynamics: Pay close attention to the latest developments and technological trends in the automotive coating industry, and adjust and optimize coating technology in a timely manner.

4. Promote the application of new technologies: Actively promote and apply new technologies, new processes and new equipment to improve the technical level and market competitiveness of coating workshops.

In summary, automotive coating workshops face five major challenges, including unstable coating quality, low production efficiency, increased environmental pressure, difficulty in cost control, and insufficient technological innovation. In response to these challenges, coating line equipment manufacturers and automobile manufacturers should work together to continuously improve the production efficiency and product quality of coating workshops and achieve sustainable development by optimizing coating formulas, refining process management, improving equipment accuracy, strengthening personnel training, simplifying coating processes, strengthening equipment maintenance, optimizing production line layout, introducing intelligent management systems, adopting environmentally friendly coatings, improving wastewater treatment technology, strengthening waste gas treatment, promoting green production, optimizing coating procurement, improving equipment utilization, reducing labor costs, strengthening cost management, increasing R&D investment, strengthening industry-university-research cooperation, paying attention to industry trends, and promoting the application of new technologies.