All categories

Related News

26

2025

-

09

How Does UV Curing Coating Save 60% Drying Time in Wooden Furniture Production?

Author:

Chuangzhi Coating

1. UV Curing Principle: A Technological Breakthrough from "Waiting for Volatilization" to "Instant Crosslinking"

- Drying time comparison: Traditional water-based wood coatings require 30-60 minutes for single-coating drying (in 25℃ environment), while UV curing coating can be fully cured in 5-8 minutes under the irradiation of 80-120W/cm² UV lamps, and the curing degree is not affected by environmental temperature and humidity;

- Efficiency superposition of multiple coatings: Solid wood furniture often requires 3-4 coating processes (primer + color paint + topcoat). The total drying time of traditional processes exceeds 4 hours. UV curing coating realizes continuous "spraying-curing" operations (with only 10 minutes between each process), and the total time can be controlled within 1 hour, increasing efficiency by more than 60%.

2. Full-Process Adaptation: Efficient Coating Design for Wooden Characteristics

- Low-temperature curing technology: Adopting a composite light source of medium-pressure mercury lamps and LED-UV, while ensuring curing speed, the surface temperature of the workpiece is controlled within 50℃ (traditional hot air drying requires 60-80℃), avoiding solid wood cracking due to high temperature or board edge sealing falling off;

- Roll coating + spray coating collaboration: For flat panels (such as wardrobe door panels), UV roll coaters are used to ensure uniform coating thickness (5-15μm) and instant curing; for carved and curved parts (such as dining chair armrests), robot UV spraying is matched with focused UV lamps to irradiate groove areas, ensuring 360° no curing dead angles for complex structures;

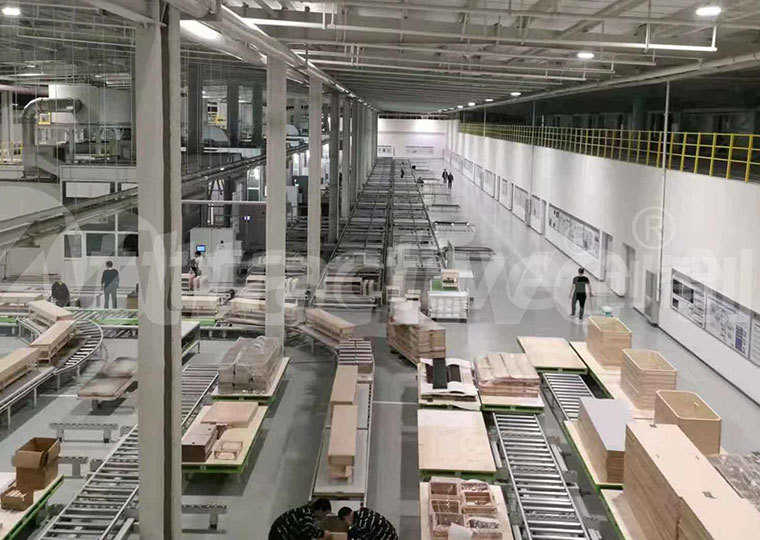

- Online flipping curing: Through automated conveyor lines and flipping mechanisms, continuous coating and curing of the front and back of the workpiece are realized without manual transfer and flipping, reducing the single-batch processing time by 40%.

3. Quality and Cost: Additional Values Beyond Efficiency Improvement

- Coating hardness leap: The pencil hardness of UV curing coating can reach 2H-3H (traditional water-based paint is mostly HB), and the scratch resistance is increased by 50%, reducing paint loss during furniture transportation and use;

- Environmental protection and material saving: UV coatings have no volatile solvents (VOCs emissions are almost zero), eliminating the need for waste gas treatment equipment; there is no material loss during curing, and the coating utilization rate reaches more than 95% (about 70% for traditional spraying);

- Energy cost reduction: Although UV lamps consume electricity, due to the extremely short drying time, the curing energy consumption per workpiece is only 1/3 of that of hot air drying. A panel furniture enterprise's calculation shows that annual electricity costs can be saved by more than 200,000 yuan.

4. Scenario Verification: Efficiency Improvement Cases for Different Wooden Categories

- Solid wood flooring: The traditional painting line has a daily output of 3,000㎡ per line. After introducing the UV curing line, through "2 coats of primer + 1 coat of topcoat" continuous curing, the daily output increases to 8,000㎡, and the proportion of drying time decreases from 60% to 20%;

- Customized wardrobes: For the special-shaped edge sealing of melamine boards, UV curing spraying can complete edge curing within 10 minutes, solving the problem of "edge sealing glue opening due to slow drying" in traditional processes, and the rework rate drops from 15% to 3%;

- Classic furniture: Carved parts adopt UV color paint spraying + local UV curing, which not only retains the clarity of the texture but also reduces the drying time from 8 hours to 1 hour, adapting to the needs of small-batch customized production.