All categories

Related News

20

2025

-

11

Dedicated Coating Lines for Automotive Component Manufacturing

Author:

Chuangzhi Coating

1. Process Customization: Exclusive Coating Logic for Different Components

- Chassis load-bearing parts (such as arms, brackets): Adopt a three-layer process of "phosphating + electrophoresis + powder coating". The anti-corrosion coating system for automotive parts achieves salt spray resistance exceeding 1000 hours (ASTM B117 standard) through the synergy of zinc-based phosphating film (3-5μm) and epoxy electrophoresis layer. Combined with low-temperature curing at 180℃, it avoids metal part deformation caused by high temperatures;

- Interior decorative parts (such as instrument panel brackets, door trim strips): Customize a "dust-free spraying + UV curing" process. The high-precision automotive coating equipment adopts electrostatic bell cups with an atomization particle size of 15-20μm, controlling the coating thickness at 15-25μm and color difference ΔE ≤ 0.6, meeting the exquisite appearance requirements of automotive interiors;

- Engine peripheral parts (such as cylinder head covers, intake pipes): Optimize the "high-temperature resistant coating + segmented curing" process, selecting silicone-modified coatings. After curing, the coating hardness reaches 3H, which can withstand high temperatures of 200℃, while having oil-resistant and easy-to-clean characteristics, adapting to the complex working conditions of the engine compartment.

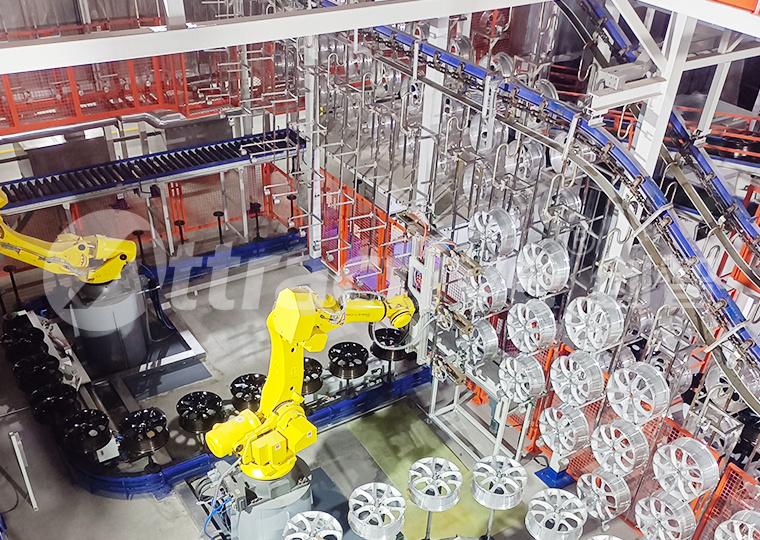

2. High-Precision Automotive Coating Equipment: Ensuring Consistency in Mass Production

- 6-axis collaborative robots + 3D visual positioning: For special-shaped components (such as complex pipelines, multi-curved brackets), automatically plan spraying paths with a repeat positioning accuracy of ±0.1mm, ensuring no missing spraying in hidden areas such as grooves and corners, with a coating coverage rate of 99.8%;

- Closed-loop parameter control system: Real-time monitor spraying pressure (±0.01MPa), coating flow rate (±1ml/min) and curing temperature (±2℃). Once deviating from the preset threshold, the system automatically corrects within 0.5 seconds, stabilizing the coating thickness deviation within ±2μm, far better than the industry standard of ±5μm;

- Rapid changeover module: Equipped with multi-color coating storage tanks and automatic cleaning gun stations. For the changeover needs of components of different vehicle models, the color change time is shortened from 30 minutes to 10 minutes, supporting more than 8 changeovers per day, adapting to "multi-variety, small-batch" flexible production.

3. Anti-Corrosion Coating Systems for Automotive Parts: Building a Core Line of Defense for Long-Term Durability

- Refined pretreatment: Adopt a five-tank process of "pre-degreasing + main degreasing + pickling + surface conditioning + phosphating", adjusting tank liquid parameters according to different substrates such as high-strength steel and aluminum alloy, ensuring complete removal of oil stains and oxide layers on the metal surface, laying a foundation for coating adhesion;

- Cathodic electrophoresis technology: Use high-throwing power electrophoretic paint to form a uniform coating (thickness 15-20μm) in areas difficult to spray such as component inner cavities and weld seams, with an electrophoresis rate of over 95%, effectively resisting the invasion of corrosive media;

- Post-treatment sealing protection: Add a gluing and sealing process after spraying, automatically applying anti-corrosion sealant to corrosion-prone areas such as threaded holes and welding seams, further improving overall corrosion resistance, meeting the 10-year/240,000-kilometer service life requirement of the automotive industry.

4. Full-Process Compliance and Services: Adapting to Strict Requirements of the Automotive Industry

- Compliance guarantee: The production line complies with the IATF16949 quality management system and GB 37822-2019 environmental protection standards, with a VOCs emission concentration of ≤30mg/m³, equipped with paint mist recovery and waste gas treatment systems, successfully passing the environmental protection audit of OEMs;

- Full-process traceability: Integrate the MES production management system to record spraying parameters, test data and equipment status of each batch of components, generating a unique traceability code that supports tracing from finished products back to raw material batches, meeting the traceability requirements of OEMs;

- Turnkey services: Provide full-process services from demand research, scheme design, equipment installation and commissioning to employee training, dispatching professional engineers to be stationed on-site for 30 days to ensure the production line meets standards upon commissioning, and providing lifelong technical support and equipment upgrade services in the later stage.

Conclusion

SEO:

Next Page