Related News

22

2026

-

01

Aluminum Wheel Automatic Painting Line: Empowering the Quality and Efficiency Revolution in High-End Wheel Manufacturing

Author:

Chuangzhi Coating

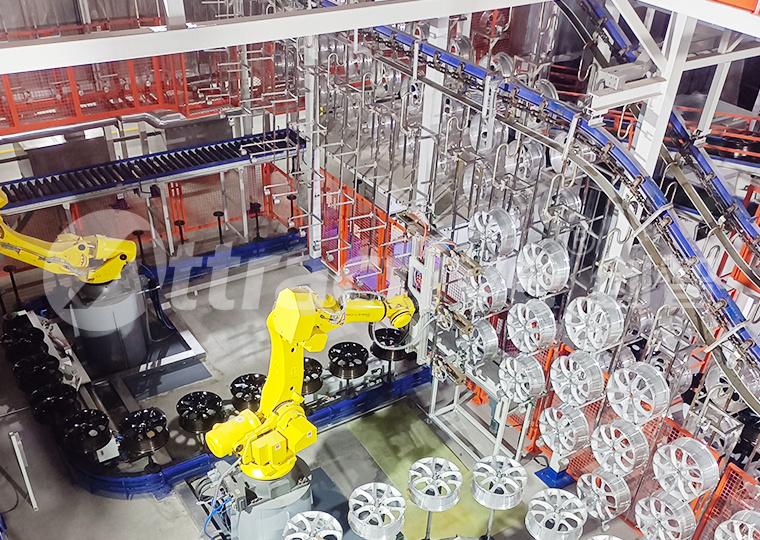

As the automotive industry advances towards lightweighting, personalization, and premiumization, aluminum alloy wheels have become a standard feature and a critical aesthetic element. Their surface coating quality directly impacts a vehicle's visual appeal, corrosion resistance, and brand value. Therefore, a highly specialized and automated Aluminum Wheel Automatic Painting Line has become an essential production system for leading wheel manufacturers. It integrates advanced robotics, precise process control, and intelligent management, providing the ultimate solution to meet stringent OEM standards and mass customization demands.

Industry Challenges and the Need for Automation

Aluminum wheel coating presents unique challenges: the substrate is aluminum alloy, requiring special pre-treatment for adhesion; wheels have complex three-dimensional shapes and surfaces, demanding extremely high coating uniformity; market requirements are diverse, ranging from high-gloss and matte finishes to special color effects, necessitating highly flexible processes; simultaneously, pressures on capacity, cost, and environmental compliance persist. Traditional manual or semi-automated spraying can no longer cope, driving the adoption of the Aluminum Wheel Automatic Painting Line. This fully automated wheel coating system ensures that every single wheel, from loading to unloading, receives stable, consistent, and high-quality surface treatment through precise automated procedures.

Core Components and Process Flow of an Aluminum Wheel Automatic Painting Line

A complete Aluminum Wheel Automatic Painting Line is a systematic project, typically comprising the following key modules that form a seamlessly connected continuous production line:

Intelligent Logistics and Pre-treatment System: The system begins with automatic loading and conveying (often using power-and-free overhead chains or floor pallet systems), ensuring efficient, scratch-free wheel transfer. The pre-treatment stage is critical, including steps like degreasing, etching, chromating, or chrome-free conversion coating, specifically designed for aluminum alloys to create a perfect coating substrate that enhances adhesion and corrosion resistance.

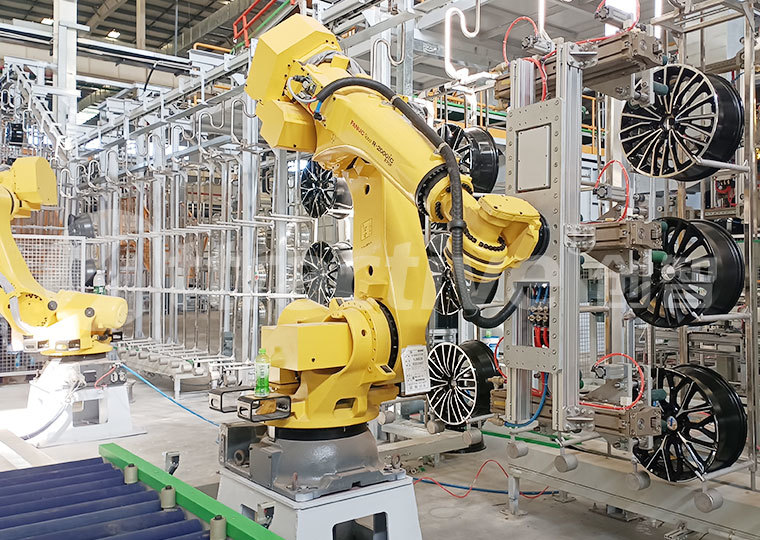

Automated Spraying Core Unit: This is the "heart" of the line. Multiple high-precision 6-axis painting robots work in coordination. Their movement paths are optimized through offline programming and 3D simulation, ensuring the spray gun covers every complex surface of the wheel—including hard-to-reach areas like the back of spokes and bolt holes—at the optimal angle and distance. Combined with high-speed rotary atomizers (e.g., bells) and electrostatic application technology, they achieve high transfer efficiency (over 90%) and exceptional uniformity. For special processes like two-tone wheels or brushed finishes, robots integrated with vision positioning systems enable millimeter-precision masking or localized spraying.

Efficient Drying and Curing System: After spraying, wheels enter precisely temperature-controlled ovens. The line often employs a "three-coat three-bake" or "two-coat two-bake" process (i.e., primer, basecoat, clear coat, with respective curing). Ovens use clean energy (e.g., natural gas) and are equipped with heat recovery systems, maximizing energy efficiency while ensuring the coating fully cross-links and cures to achieve optimal hardness and gloss.

Integrated Quality Inspection and Closed-Loop Control: Advanced Aluminum Wheel Automatic Painting Lines integrate online film thickness measurement, gloss measurement, and even AI-based visual defect detection systems. Real-time data is fed back to the central control system (MES/SCADA), allowing dynamic fine-tuning of robot spraying parameters, enabling closed-loop control and traceability of production quality.

Strategic Value of Investing in an Aluminum Wheel Automatic Painting Line

Exceptional and Stable Coating Quality: Automation eliminates the variability of manual operation, ensuring batch products have unparalleled consistency in appearance and performance reliability, easily meeting top-tier OEM standards.

Significantly Improved Production Efficiency and Capacity: The line operates continuously 7x24 with precise cycle times, dramatically increasing output. Quick color-change systems and flexible programming also reduce changeover time for small-batch, high-mix orders.

Substantial Reduction in Overall Operating Costs: High transfer efficiency and material utilization directly reduce paint consumption; reliance on skilled painters is reduced, lowering labor costs and training difficulties; stable quality also significantly reduces rework and scrap rates.

Achieving Green Environmental Standards and Safe Production: Enclosed automated spray booths and efficient centralized exhaust treatment systems (e.g., RTO) minimize VOC emissions; they also remove workers from the hazardous spray environment, complying with the highest health and safety standards.

Empowering Smart Manufacturing and Data-Driven Operations: As a key node in a smart factory, the line generates vast amounts of data usable for analytical optimization, predictive maintenance, and digital management, supporting continuous process improvement and intelligent decision-making.

Selection and Implementation Considerations

Investing in an Aluminum Wheel Automatic Painting Line is a major decision. The key to success lies in selecting a supplier with profound industry expertise. The partner must be capable of providing a comprehensive turnkey solution—from process lab validation, line layout planning, and equipment integration to installation, commissioning, and long-term technical support. During evaluation, focus on the supplier's successful case studies in the aluminum wheel sector, the precision of their robot path simulation, the line's energy-saving and environmental indicators, and its scalability for future upgrades.

Conclusion

Facing increasingly fierce market competition and ever-rising quality demands, the Aluminum Wheel Automatic Painting Line has evolved from an advanced piece of equipment into a strategic cornerstone for wheel manufacturers building core competitiveness. It is not merely a collection of equipment for automated painting but a systemic engineering project integrating materials science, precision machinery, robotics, and digital information technology. By deploying such an intelligent production line, manufacturers can not only consistently produce high-quality wheels that rival OEM standards in gloss and durability but also navigate the transformative waves of the future automotive industry with superior flexibility, efficiency, and sustainability, progressing steadily on the path of high-end manufacturing.

SEO:

Previous