编号 :

Attractivechina2025081437

Solid Wood Coating Equipment Furniture Coating Line with Reciprocating Spray Machine

零售价

市场价

Technology at home and abroad

Quality assurance

Tailored

Original purchase

全国客户服务热线 7*24小时:

+86 758-6626158-8063

重量

库存

隐藏域元素占位

- Product Details

- Product Parameters

- Product Properties

-

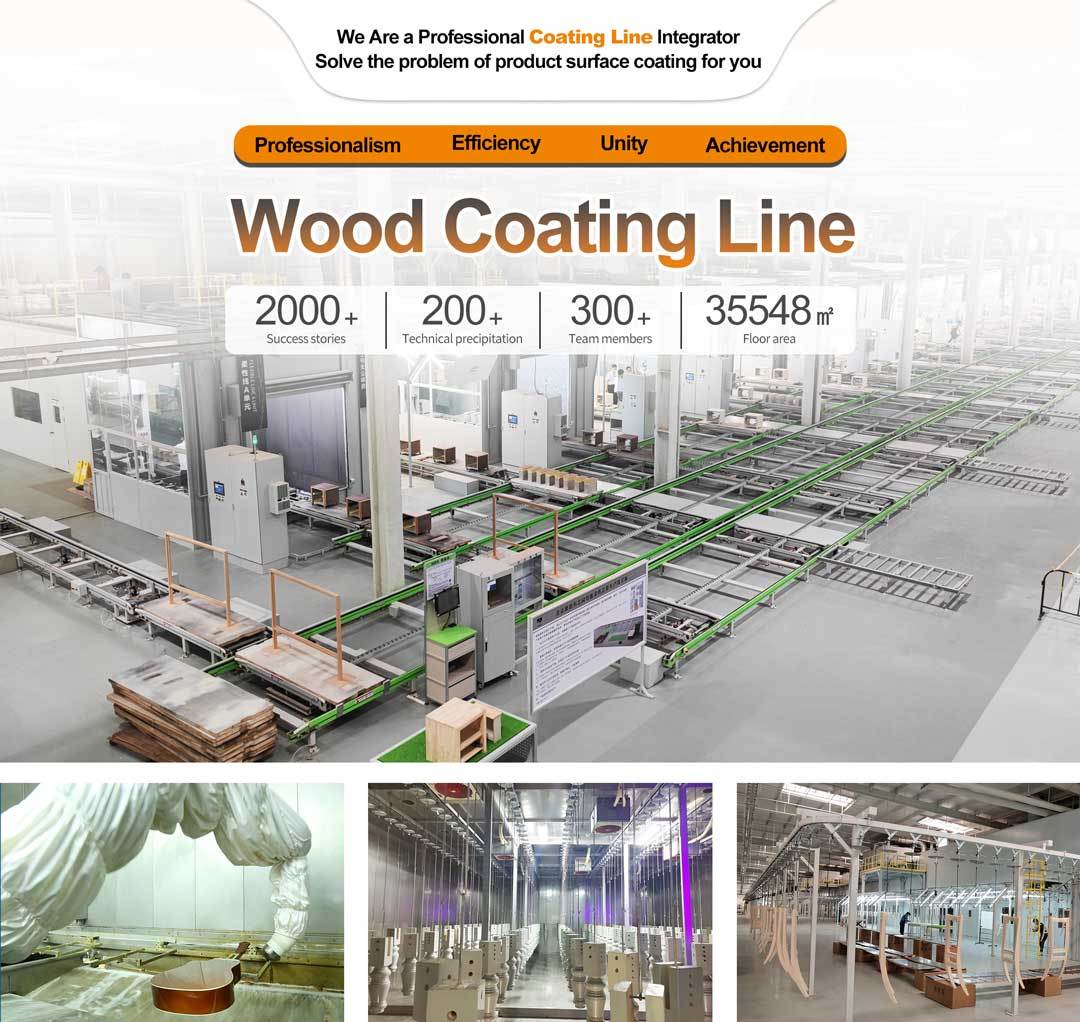

Wood Coating Line

Reciprocating Spray Machine

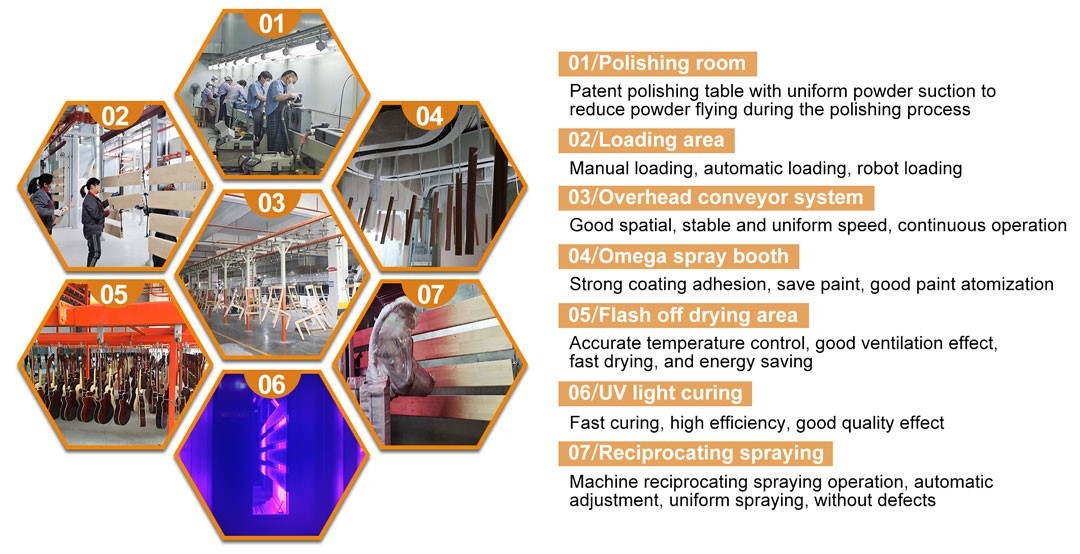

Efficient spraying technology: The reciprocating spray machine adopts a unique reciprocating motion principle, which can achieve uniform coating application on different working surfaces. Its precise control system can automatically adjust the spray path according to the size and shape of the product, ensuring that every corner can be fully covered. The equipment is equipped with efficient nozzles that can produce tiny paint particles, greatly improving the coating quality and adhesion. At the same time, the quick replacement function of the reciprocating spray machine reduces production downtime, making the production process smoother and adapting to the needs of small batch diversified production.Coating Equipment

Multi-functional coating solution: The coating equipment integrates a number of advanced technologies and supports a variety of coating types, such as water-based, oil-based and special functional coatings, to meet the needs of different industries. The equipment design focuses on flexibility and can adapt to the coating requirements of different products through simple setting adjustments. The intelligent control system provides real-time monitoring and feedback to ensure the consistency and uniformity of the coating. In addition, the modular design of the coating equipment makes maintenance and upgrades easier, helping companies stay competitive and reduce operating costs.Furniture Coating Line

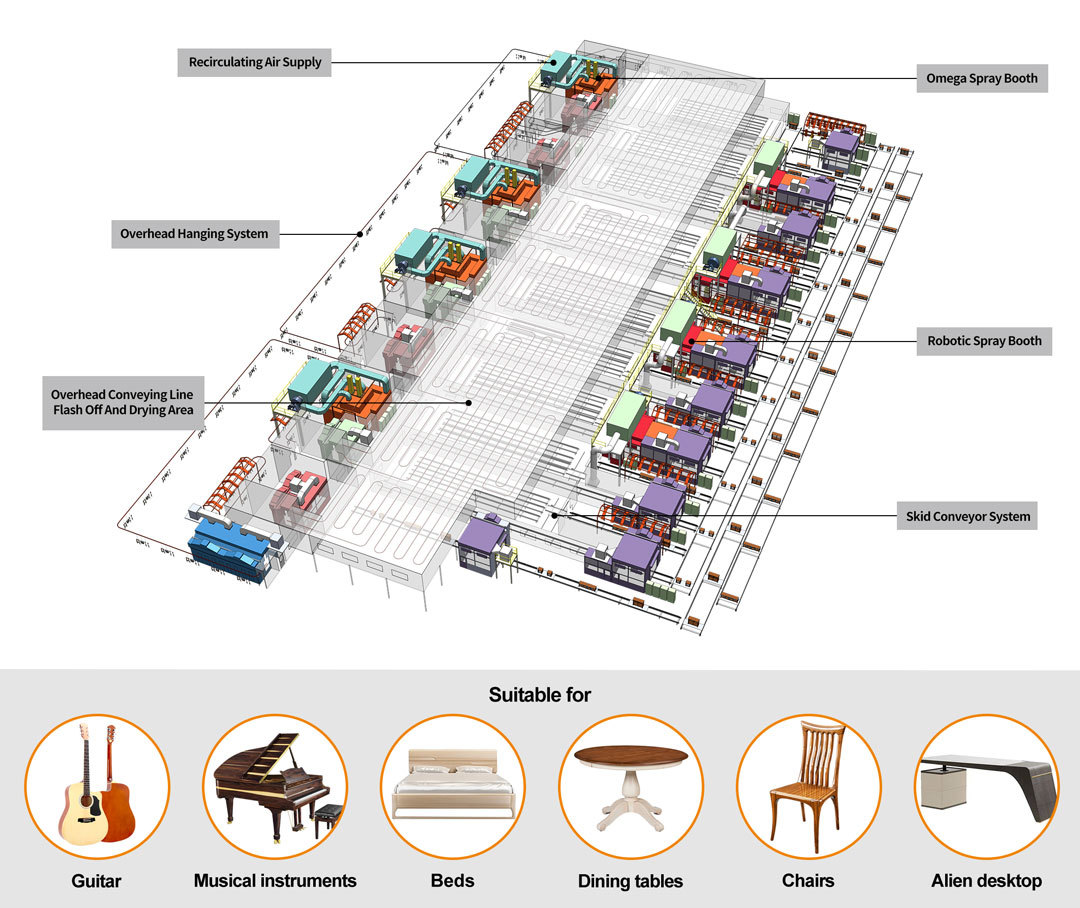

Specialized furniture coating system: The furniture coating line is designed for efficient processing of various furniture products, with a high degree of automation from pretreatment, spraying to drying. The line uses advanced coating technology to ensure perfect adhesion of the coating on different materials such as wood, metal or plastic. Through intelligent process control, the system can monitor the coating effect in real time to ensure that each piece of furniture can achieve high-quality appearance and protection performance. The furniture coating line also takes environmental factors into consideration and can effectively reduce the volatile organic compounds (VOCs) of the coating, meet modern environmental standards, and contribute to the sustainable development of the enterprise.

Technological Process

Wood Coating Line

Loading→Primer 1 spraying→Primer 2 spraying→Glue spraying→Wiping→Primer→Dry brush→Two coats of primer→Tint→Top-coat→Inspection area→Finished product drying→Unloading

-

Workpiece: Guitar, musical instruments, beds, dining tables, chairs, alien desktop, etc. Workpiece material: Solid wood, medium fiber board, veneer particleboard Work system: 300 days/year; 20H/day; equipment utilization rate: 85% Spray booth temperature: 18~26°C Spray room humidity: 45~75%RH Spraying method: Artificial/Robotic Tool tray size: L2300 * W800 * H2200mm (reference) Production rhythm: 1.0min-4min/pry (depending on different workpieces) Workpiece weight: 300KG Power: 380V 3φ 50 Hz Compressed air: Pressure≥0.7MPa±5%(Gauge pressure)、oil<0.01mg/m³ 、solid <1.00mg/m³ 、dew point 0.6Mpa -20℃ Natural gas: Standard pressure is medium pressure 80kPa Tap water: Pressure≥1.5Kg/㎝2 Heating energy: Electricity, natural gas Note: Above data for reference only, the actual data will be calculated according to customer require -

Brand Name Attractivechina Dimension(L*W*H) Customized Design Place of Origin Guangdong, China Advantage High-efficiency,environmental-protection Production Capacity Depending on customer needs After-sales Service Provided Engineers available to service machinery overseas Product certificate EAC/CE,ISO14001,ISO45001,1SO9001

Related Products