编号 :

Attractivechina2025081436

Wood Spray Coating Line Electrostatic Door Painting Machine Coating System

零售价

市场价

Technology at home and abroad

Quality assurance

Tailored

Original purchase

全国客户服务热线 7*24小时:

+86 758-6626158-8063

重量

库存

隐藏域元素占位

- Product Details

- Product Parameters

- Product Properties

-

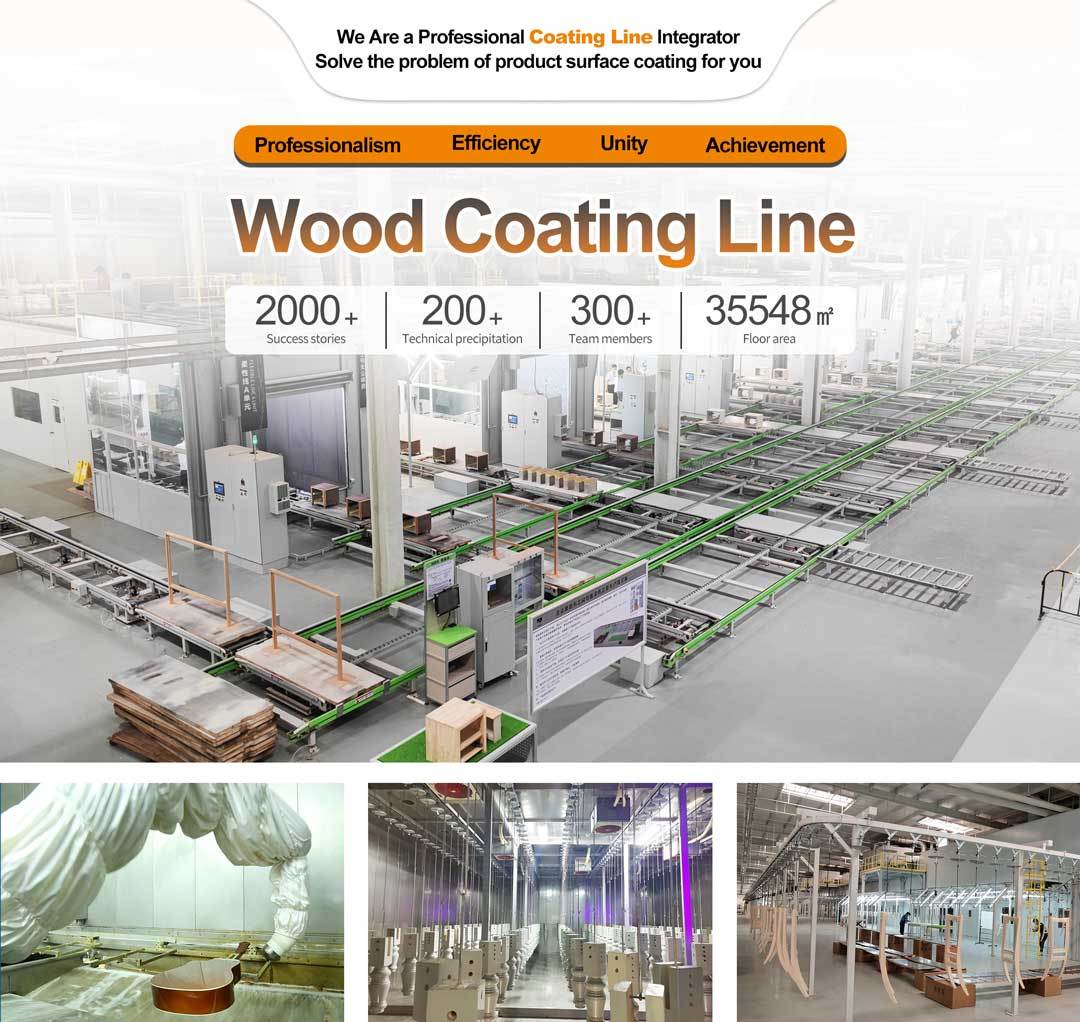

Wood Coating Line

Wood Spray Coating Line

Automated coating process: The wood spray coating line optimizes the wood coating process through a highly automated system. The line forms a seamless closed loop from pretreatment, spraying to drying. Its advanced spraying technology uses high-efficiency nozzles to evenly spray the paint on the wood surface, ensuring that every part is fully covered. In addition, the system is equipped with intelligent monitoring, which can adjust the spraying parameters in real time to adapt to different types and shapes of wood. All this not only improves production efficiency, but also significantly reduces paint waste, ensuring that wood products have lasting beauty and protection.Coating System

Integrated coating solution: The coating system combines a variety of advanced technologies to provide an integrated coating solution for various industries and products. Its modular design allows the system to be flexibly configured according to specific needs to adapt to a variety of coating tasks. The system's built-in intelligent control and monitoring functions can track coating thickness, uniformity and other key indicators in real time to ensure that each batch of products meets strict quality standards. In addition, the coating system also pays attention to environmental protection, using low-VOCs paint and efficient exhaust gas treatment devices to help companies achieve sustainable development goals and provide strong support for a win-win situation for environmental protection and economy.

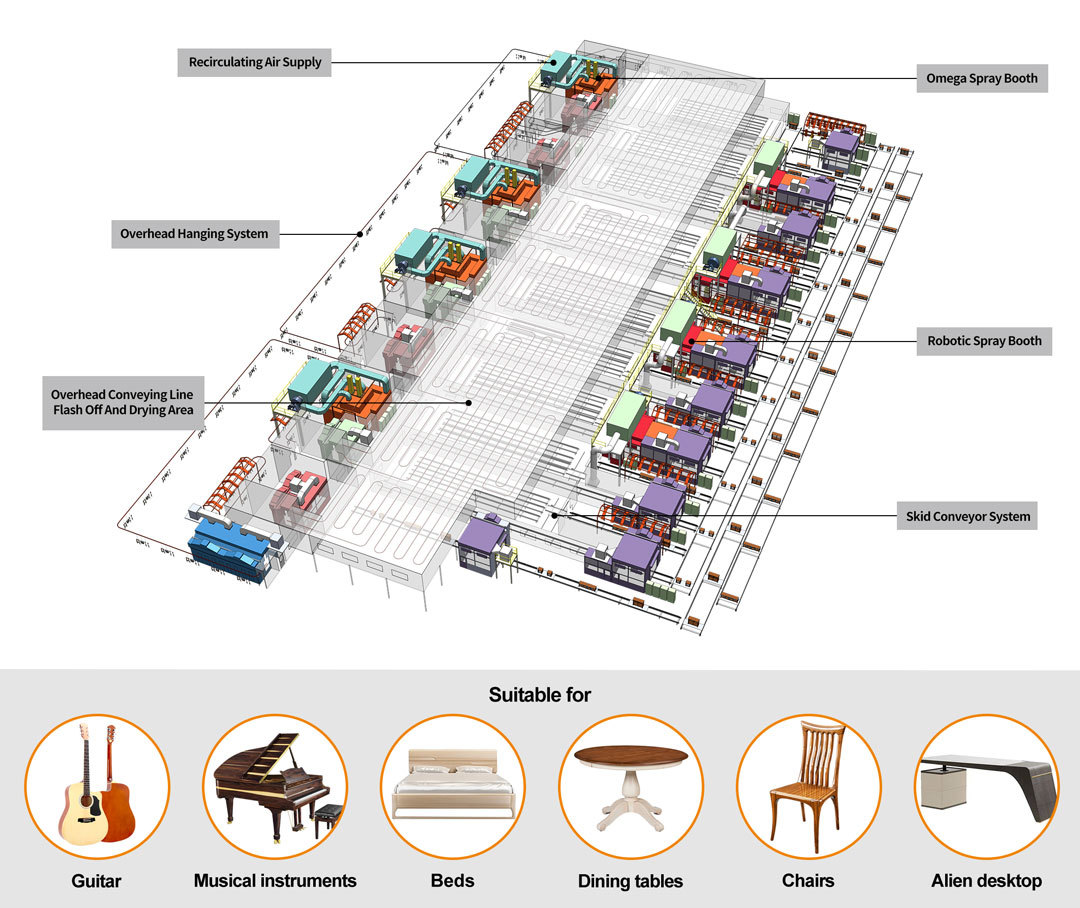

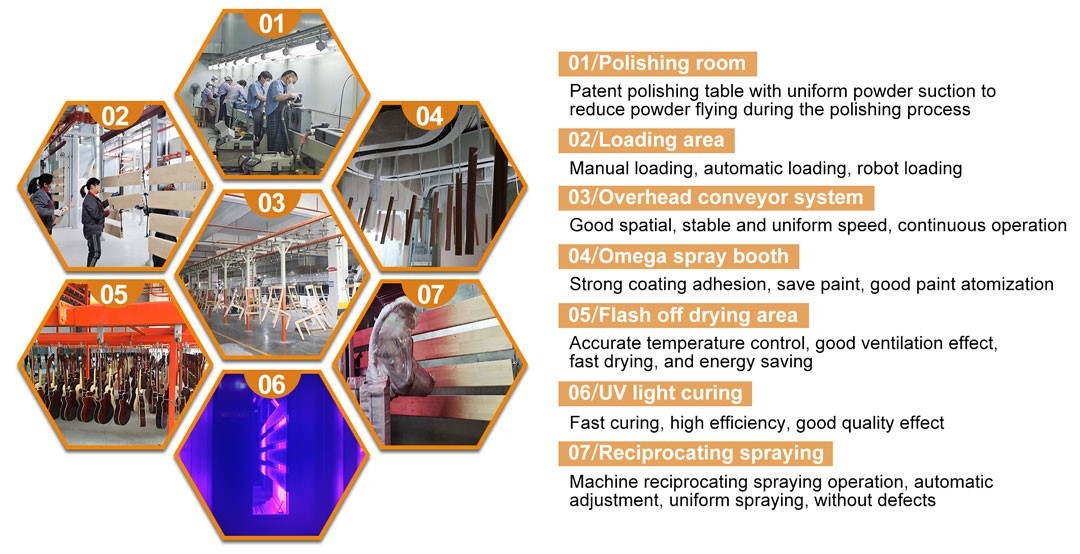

Technological Process

Wood Coating Line

Loading→Primer 1 spraying→Primer 2 spraying→Glue spraying→Wiping→Primer→Dry brush→Two coats of primer→Tint→Top-coat→Inspection area→Finished product drying→Unloading

-

Workpiece: Guitar, musical instruments, beds, dining tables, chairs, alien desktop, etc. Workpiece material: Solid wood, medium fiber board, veneer particleboard Work system: 300 days/year; 20H/day; equipment utilization rate: 85% Spray booth temperature: 18~26°C Spray room humidity: 45~75%RH Spraying method: Artificial/Robotic Tool tray size: L2300 * W800 * H2200mm (reference) Production rhythm: 1.0min-4min/pry (depending on different workpieces) Workpiece weight: 300KG Power: 380V 3φ 50 Hz Compressed air: Pressure≥0.7MPa±5%(Gauge pressure)、oil<0.01mg/m³ 、solid <1.00mg/m³ 、dew point 0.6Mpa -20℃ Natural gas: Standard pressure is medium pressure 80kPa Tap water: Pressure≥1.5Kg/㎝2 Heating energy: Electricity, natural gas Note: Above data for reference only, the actual data will be calculated according to customer require -

Brand Name Attractivechina Dimension(L*W*H) Customized Design Place of Origin Guangdong, China Advantage High-efficiency,environmental-protection Production Capacity Depending on customer needs After-sales Service Provided Engineers available to service machinery overseas Product certificate EAC/CE,ISO14001,ISO45001,1SO9001

Related Products