编号 :

Attractivechina2025081112

Robot Painting Machine Automatic Powder Coating Equipment Auto Parts Coating Line

零售价

市场价

Technology at home and abroad

Quality assurance

Tailored

Original purchase

SEO:

全国客户服务热线 7*24小时:

+86 758-6626158-8063

重量

库存

隐藏域元素占位

- Product Details

- Product Parameters

- Product Properties

-

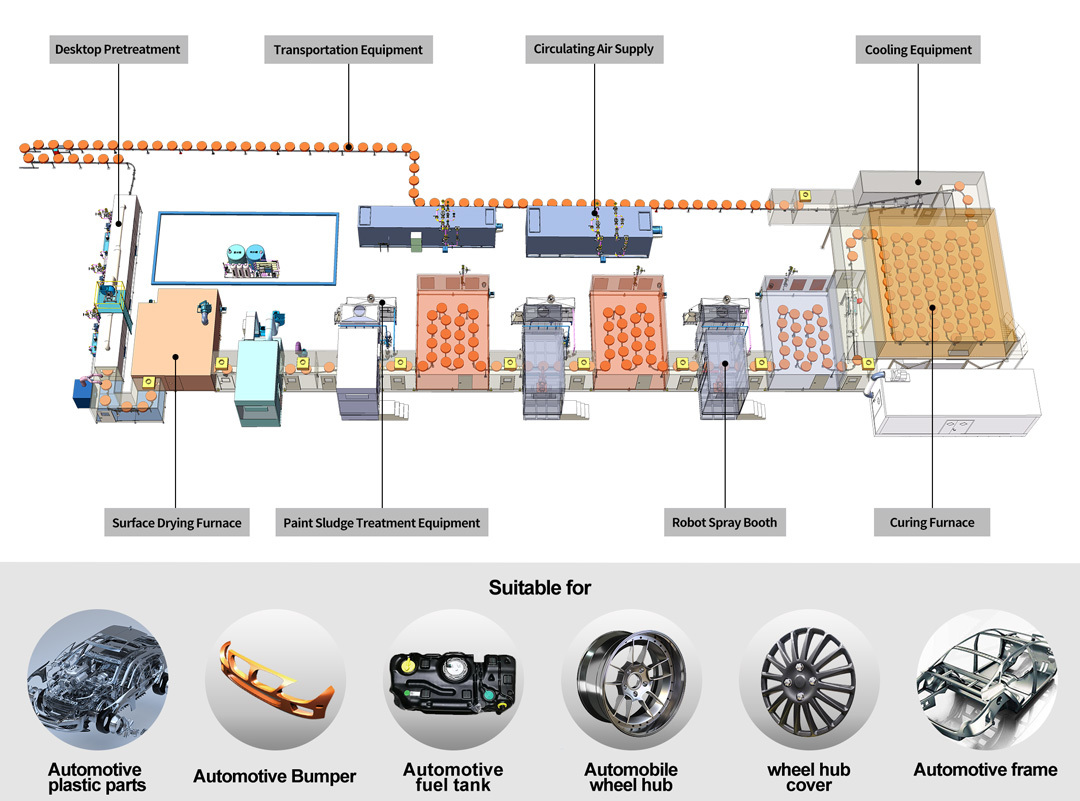

The auto parts coating line is a specialized setup designed to provide high-quality coatings for automotive components. It incorporates advanced techniques and technologies to ensure precise and durable finishes. In the automotive industry in China, this coating line is crucial for enhancing the appearance and protection of various auto parts. It allows for consistent and reliable coating applications, meeting the demanding standards of the sector.

The auto parts coating line is a complex and efficient system that caters to the coating needs of auto parts. It offers a seamless process, from surface preparation to the application of coatings. With its ability to handle different types of auto parts, it ensures uniformity and quality throughout. In the manufacturing landscape of China, this line is highly regarded for its contribution to the production of top-notch auto parts with superior coatings.

The auto parts coating line is an integral part of the automotive manufacturing process. It provides a dedicated and optimized solution for coating auto parts. Utilizing state-of-the-art equipment and materials, it guarantees excellent adhesion and finish. In the context of China's automotive industry, this coating line is essential for delivering auto parts with enhanced aesthetics and resistance. It helps manufacturers meet the increasing demands for quality and performance in the automotive market.

Auto Parts Coating Line

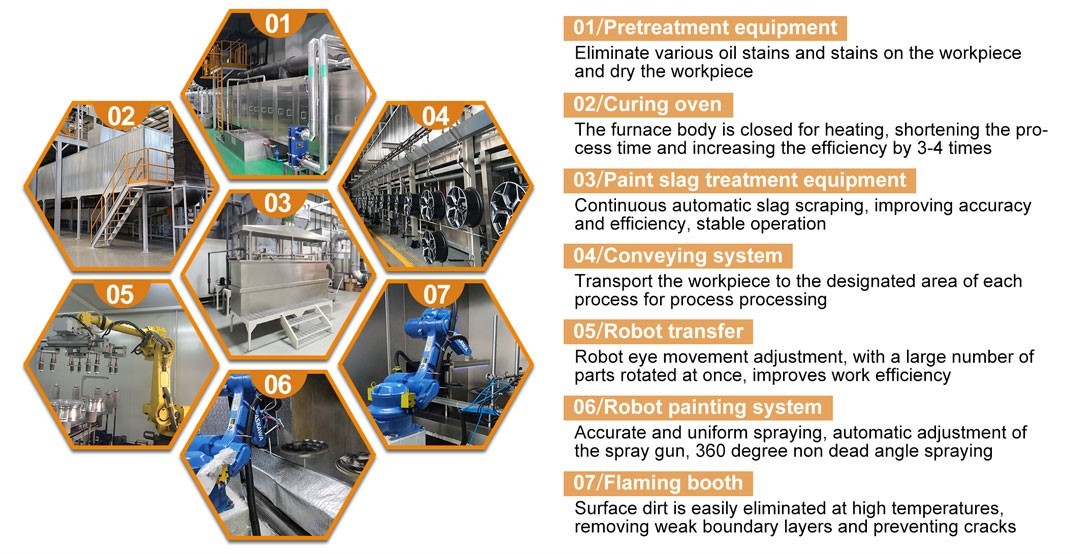

1. Our spraying booth designs high efficiency of paint or powder capture, maintenance free.

2. low energy consumption, 15-35% less than others.

3. A number of patent designs, site measurement and customized design.

4. The production line with more than 15 years of service life, and low maintenance and high safety.

5. The whole line provides remote monitoring and easy to maintenance.

6. High level of automation, reduce labor costs, visual logo easy to manage.

7. Provide explosion-proof design requirements;

8. Electrostatic spraying to save paint and reduce cost.

9. Environmental protection equipment meets the national environmental VOC emission standards.

Technological Process

-

Workpiece: Automotive bumper, wheel hub, wheel hub cover, automotive fuel tank, frame, etc Workpiece material: ABS、PS、PPE、PA Work system: 300 days/year; 20H/day; equipment utilization rate: 85% Spray booth temperature: 25±3°C Spray room humidity: 65±5%RH Spraying method: Robot Maximum installation size of round Fixture: φ600×H150mm Fixture workpiece pitch: 300, 600, 900mm Conveyor speed: 500mm/min (1-3m/min Adjustable) Length of conveyor belt: About 255M Plant size: 80m(L)*30m(W)*11m(H) Power: 380V 3φ 50 Hz Compressed air: Pressure≥0.7MPa±5% oil<0.01mg/m³ solid <1.00mg/m³ dew point 0.6Mpa -20℃ Natural gas: Standard pressure is medium pressure 80kPa Tap water: Pressure≥1.5Kg/㎝2 Heating energy: Electricity, natural gas Note: Above data for reference only, the actual data will be calculated according to customer require -

Brand Name Attractivechina Dimension(L*W*H) Customized Design Place of Origin Guangdong, China Advantage High-efficiency,environmental-protection Production Capacity Depending on customer needs After-sales Service Provided Engineers available to service machinery overseas Product certificate EAC/CE,ISO14001,ISO45001,1SO9001

Related Products