编号 :

Attractivechina2025081407

Aluminium Wheel Coating Line Automatic Spray Machine Automotive Painting Equipment

零售价

市场价

Technology at home and abroad

Quality assurance

Tailored

Original purchase

SEO:

全国客户服务热线 7*24小时:

+86 758-6626158-8063

重量

库存

隐藏域元素占位

- Product Details

- Product Parameters

- Product Properties

-

Product advantages

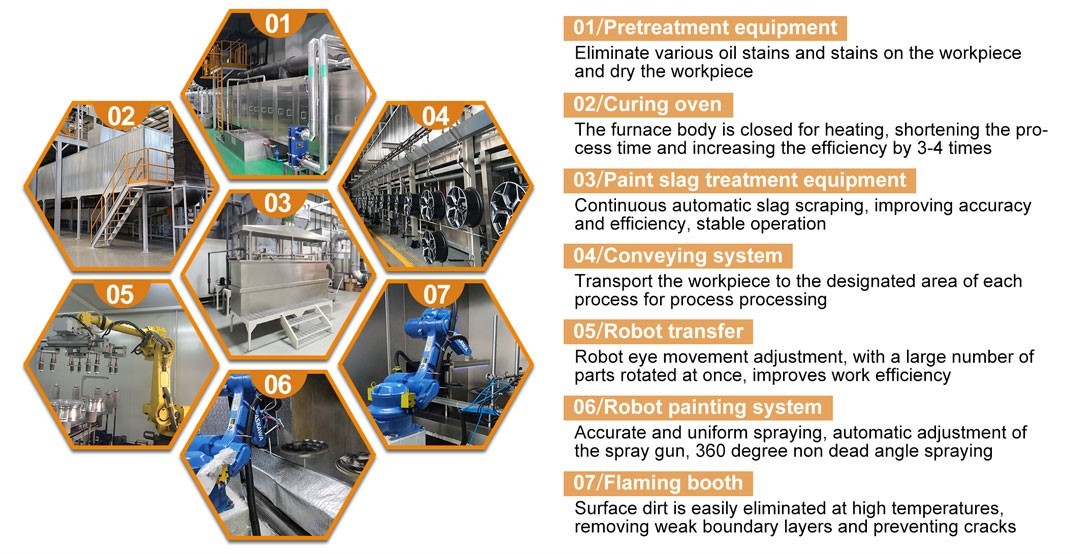

1. Efficient and automated production: Aluminium Wheel Coating Line adopts advanced automation control technology to realize the fully automated process from wheel hub loading, surface treatment, primer spraying, mid-coat, topcoat spraying to drying and curing, greatly improving production efficiency, reducing manual intervention, and ensuring stable and reliable production rhythm.

2. Precision spraying technology: Equipped with high-precision spray guns and intelligent control systems, it can automatically adjust the spraying trajectory and spray volume according to the shape and size of the wheel hub, achieve a uniform and delicate coating effect, and reduce paint waste. At the same time, it improves the appearance quality of the product to ensure that each wheel hub can present a perfect coating effect.

3. Environmental protection and energy-saving design: Environmentally friendly paint and advanced exhaust gas treatment system are used to effectively reduce VOCs (volatile organic compounds) emissions, in line with national environmental protection standards. At the same time, the production line design focuses on energy efficiency, such as the use of efficient and energy-saving drying furnaces and heat recovery systems to reduce energy consumption and achieve green production.

4. Flexibility and scalability: The production line is flexible in design and can be customized according to customer needs to meet the production needs of aluminum alloy wheels of different specifications and models. At the same time, expansion interfaces are reserved to facilitate future capacity upgrades or access to new functional modules, protecting customer investments and extending the service life of the production line.

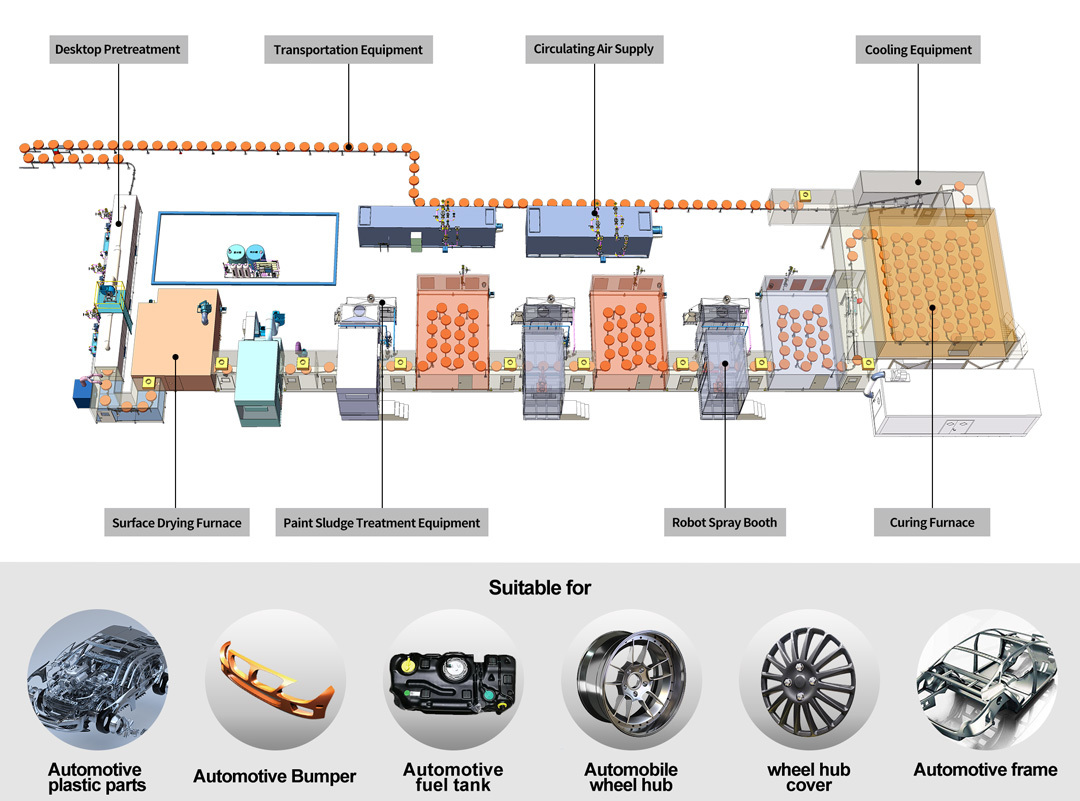

Auto Parts Coating Line

The Automatic Spray Machine provides consistent and even coverage, guaranteeing a flawless finish on each wheel. With its advanced technology, it can handle the complexities of aluminum wheel surfaces, such as intricate designs and curves, with ease. This ensures that the coating adheres perfectly, enhancing the durability and aesthetic appeal of the wheels.

Technological Process

Auto Parts Coating Line

Loading→Degreasing→Rinsing→Pure water washing→Water blowing→Moisture drying→Cooling→Flame treatment→Automatic electrostatic dust removal→Primer spraying→Surface drying→Mid-paint spraying→Surface drying→Top-coat spraying→Surface drying→Curing→Cooling→Unloading→Inspection and packaging

-

Workpiece: Automotive bumper, wheel hub, wheel hub cover, automotive fuel tank, frame, etc Workpiece material: ABS、PS、PPE、PA Work system: 300 days/year; 20H/day; equipment utilization rate: 85% Spray booth temperature: 25±3°C Spray room humidity: 65±5%RH Spraying method: Robot Maximum installation size of round Fixture: φ600×H150mm Fixture workpiece pitch: 300, 600, 900mm Conveyor speed: 500mm/min (1-3m/min Adjustable) Length of conveyor belt: About 255M Plant size: 80m(L)*30m(W)*11m(H) Power: 380V 3φ 50 Hz Compressed air: Pressure≥0.7MPa±5% oil<0.01mg/m³ solid <1.00mg/m³ dew point 0.6Mpa -20℃ Natural gas: Standard pressure is medium pressure 80kPa Tap water: Pressure≥1.5Kg/㎝2 Heating energy: Electricity, natural gas Note: Above data for reference only, the actual data will be calculated according to customer require -

Brand Name Attractivechina Dimension(L*W*H) Customized Design Place of Origin Guangdong, China Advantage High-efficiency,environmental-protection Production Capacity Depending on customer needs After-sales Service Provided Engineers available to service machinery overseas Product certificate EAC/CE,ISO14001,ISO45001,1SO9001

Related Products