编号 :

Attractivechina2025080617

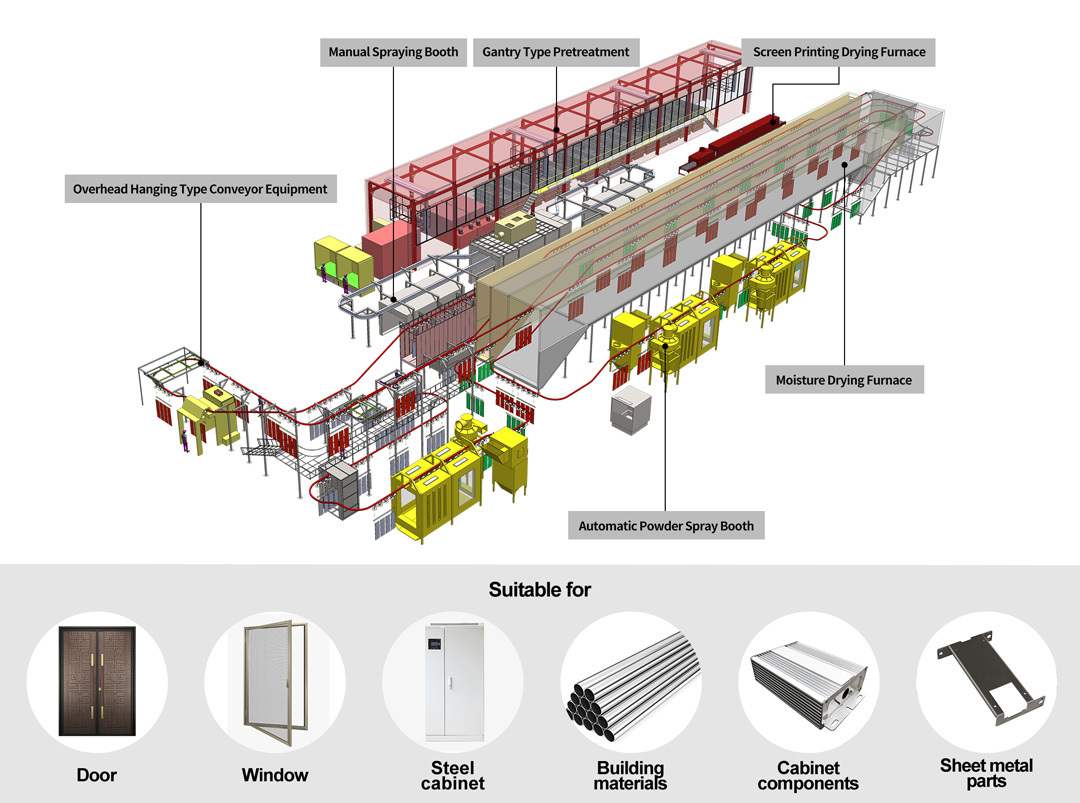

Automatic Electrostatic Powder Coating Line System For Electrical Cabinets

零售价

市场价

Technology at home and abroad

Quality assurance

Tailored

Original purchase

SEO:

全国客户服务热线 7*24小时:

+86 758-6626158-8063

重量

库存

隐藏域元素占位

- Product Details

- Product Parameters

- Product Properties

-

The automated operation process is a major feature of the system. Through the fully automatic spraying process, the system reduces the need for manual operation and improves production efficiency and consistency. Automation also means less manual intervention, thereby reducing operating errors and production costs, ensuring that each electrical cabinet can achieve a high standard of coating effect.

The application of electrostatic spraying technology enables the powder coating to form a uniform coating on the surface of the electrical cabinet. The electrostatic effect not only improves the adhesion of the powder, but also effectively reduces the waste of powder. The high efficiency and environmental protection of this technology make it an ideal choice for the modern coating industry, which can significantly improve the quality of coating and the economic benefits of production.

The intelligent control function of the system provides precise operation and monitoring capabilities. Through the advanced control panel, users can easily set the spraying parameters and monitor the coating process in real time to ensure that each electrical cabinet can obtain consistent coating quality. In addition, the real-time data feedback of the system also helps users to adjust production parameters in time and optimize the production process.

Metal Coating Line

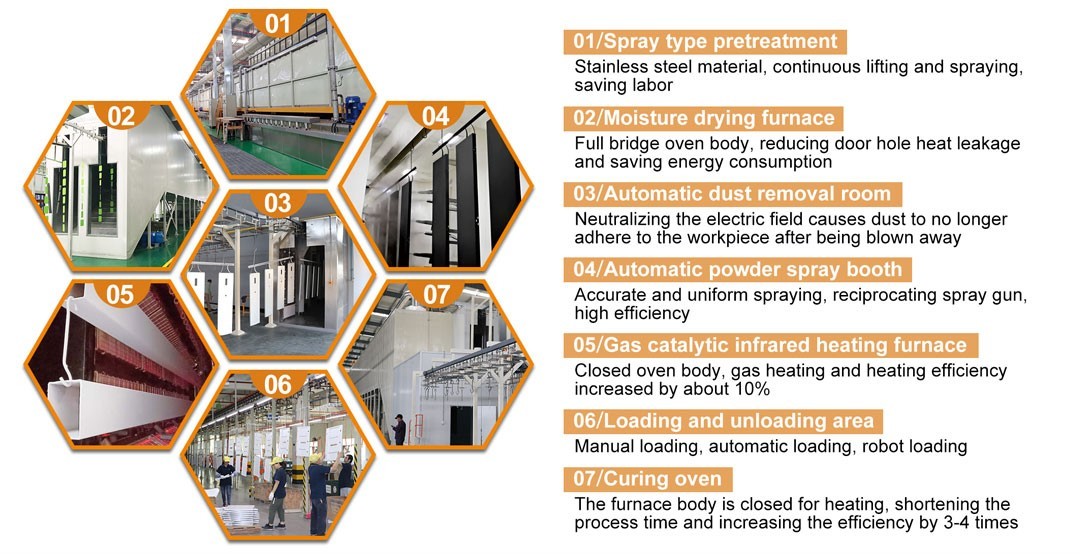

1. Automatic transmission, speed up to 8m/min, high production efficiency.

2. before spraying, dust removal process to ensure surface does not exist > 0.1mm dust.

3. The pre-heat treatment of dehumidification treatment, no oil and water marks on the surface, and increase the adsorption effect of the paint.

4. Wonderful and accurate surface coating, qualified rate is more than 95%.

5. Imported painting pump, imported spray gun and high precision flow ratio valve, save 30% paint material.

6. The air supply through 4 filters, ensure that the dustless spray room meets the dust free level standard.

7. Paint mist removal system: centrifugal mist exhaust fan, exhaust the mist in 2 seconds.

8. PLC central control system, automation control, one button operation, convenient and safe.

Technological Process

-

Workpiece: Door, window, steel cabinet, building materials, cabinet components, sheet metal parts etc. Workpiece material: Iron, galvanized Work system: 300 days/year; 22H/day; equipment utilization rate: 85% Spraying method: Robot + manual powder spraying + reciprocating machine Maximum workpiece size of suspension line: 3000mm(L)x1000mm(W)x1800mm(H) 1mm/Hang Suspension line conveying method: 250 type double guide roller conveyor chain Chain pitch of suspension line: 250mm Hanging line workpiece pitch: 3500mm Hanging wire hanging method: Double point hanging, single point lifting weight 50kg Maximum workpiece production capacity : 68 pieces/H, 1496 pieces/day, 44.88 × 8500 pieces/year Conveyor speed: 4000mm/min(2000-5000mm/min Adjustable) Length of conveyor belt: About 363M Net height of factory building: 13m(H) Power: 380V 3φ 50 Hz Compressed air: Pressure≥0.7MPa±5% oil<0.01mg/m³ solid <1.00mg/m³ dew point 0.6Mpa -20℃ Natural gas: Standard pressure is medium pressure 80kPa Tap water: Pressure≥1.5Kg/㎝2 Heating energy: Electricity, natural gas Note: Above data for reference only, the actual data will be calculated according to customer require -

Brand Name Attractivechina Dimension(L*W*H) Customized Design Place of Origin Guangdong, China Advantage High-efficiency,environmental-protection Production Capacity Depending on customer needs After-sales Service Provided Engineers available to service machinery overseas Product certificate EAC/CE,ISO14001,ISO45001,1SO9001

Related Products