编号 :

Attractivechina2025080511

Non-Stick Pan Painting Line Pretreatment Equipment Aluminum Pot Coating Line

零售价

市场价

Technology at home and abroad

Quality assurance

Tailored

Original purchase

SEO:

全国客户服务热线 7*24小时:

+86 758-6626158-8063

重量

库存

隐藏域元素占位

- Product Details

- Product Parameters

- Product Properties

-

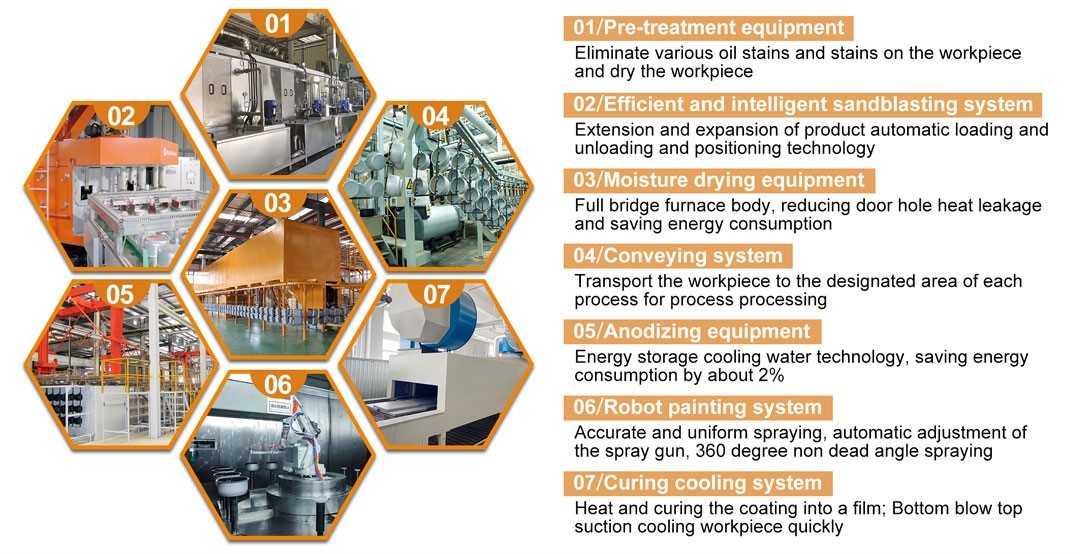

Advanced Coating Technology: The non-stick pan painting line uses the latest coating technology, focusing on improving the durability and cooking performance of the pans. The line usually uses high-performance polytetrafluoroethylene (PTFE) coating materials, which have excellent heat resistance and chemical stability, and can withstand high-temperature cooking without peeling. During the painting process, strict temperature control and humidity management are carried out to ensure that the coating is uniform and bubble-free to prevent peeling or scratching in daily use.

The Importance of Surface Pretreatment: Surface pretreatment equipment plays a vital role in the painting process, and it provides an ideal adhesion foundation for subsequent coatings. Through physical and chemical methods such as cleaning, degreasing, pickling, etc., pretreatment equipment can effectively remove impurities, oxide layers and grease on the surface of the workpiece to ensure a good bond between the coating and the substrate.

Aluminum Pot Coating Process: The aluminum pot coating line focuses on providing high-quality coating protection for aluminum cooking utensils. Aluminum is light and has excellent thermal conductivity, but its surface is susceptible to scratches and corrosion, so it is particularly important to enhance its durability through painting. This coating line usually uses high temperature curing paint to ensure that the coating remains stable at high temperatures and prevent problems with the coating during the cooking process.

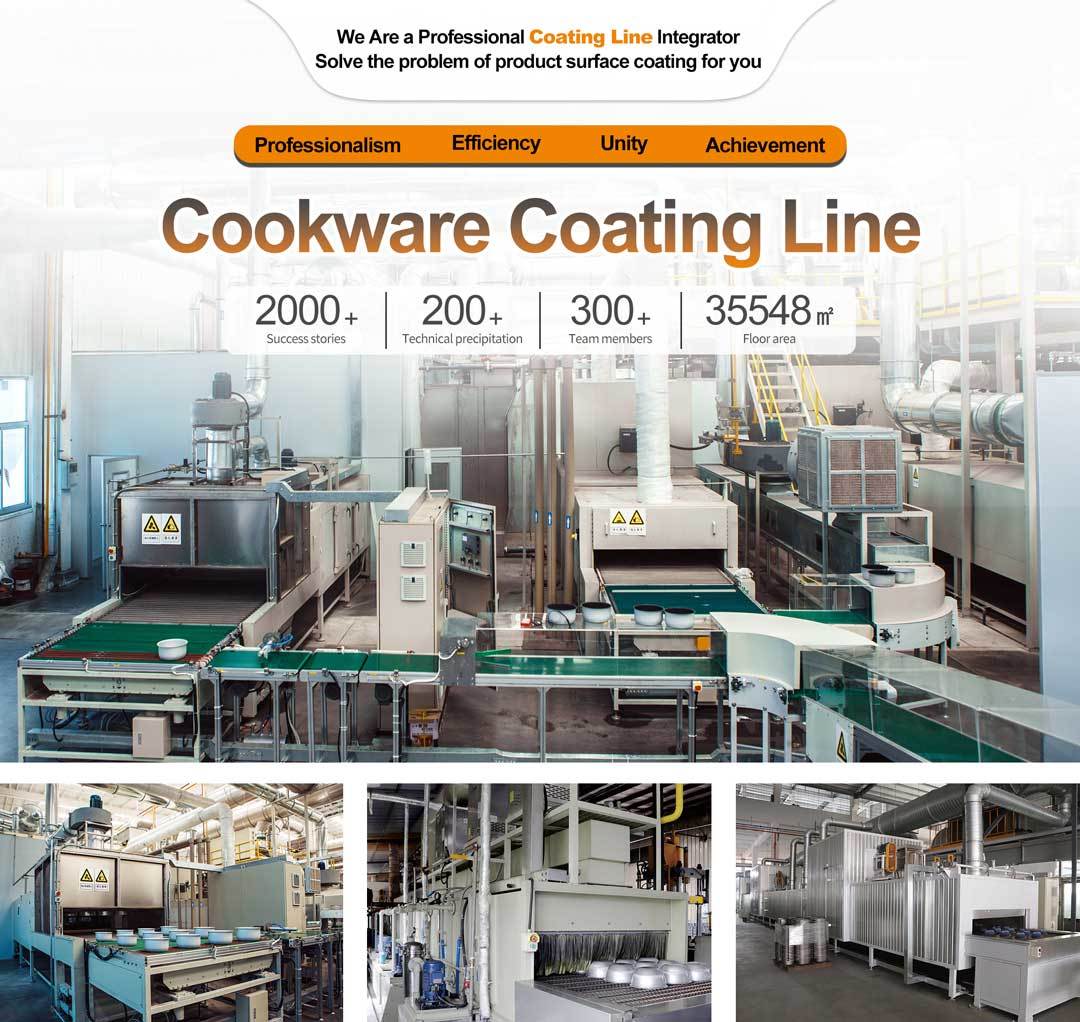

Cookware Coating Line

The AttractiveChina non-stick pan painting line is a state-of-the-art automated system designed for coating non-stick cookware, particularly frying pans and skillets. This painting line incorporates advanced technologies to ensure the efficient application of non-stick coatings such as PTFE or ceramic on the cookware’s surface. By automating the painting process, the system achieves consistent, uniform coating layers with precise thickness, enhancing the durability and performance of the pans. The non-stick coating not only improves cooking performance but also makes cleaning easier for consumers, ensuring long-lasting, high-quality results for manufacturers in the cookware industry.

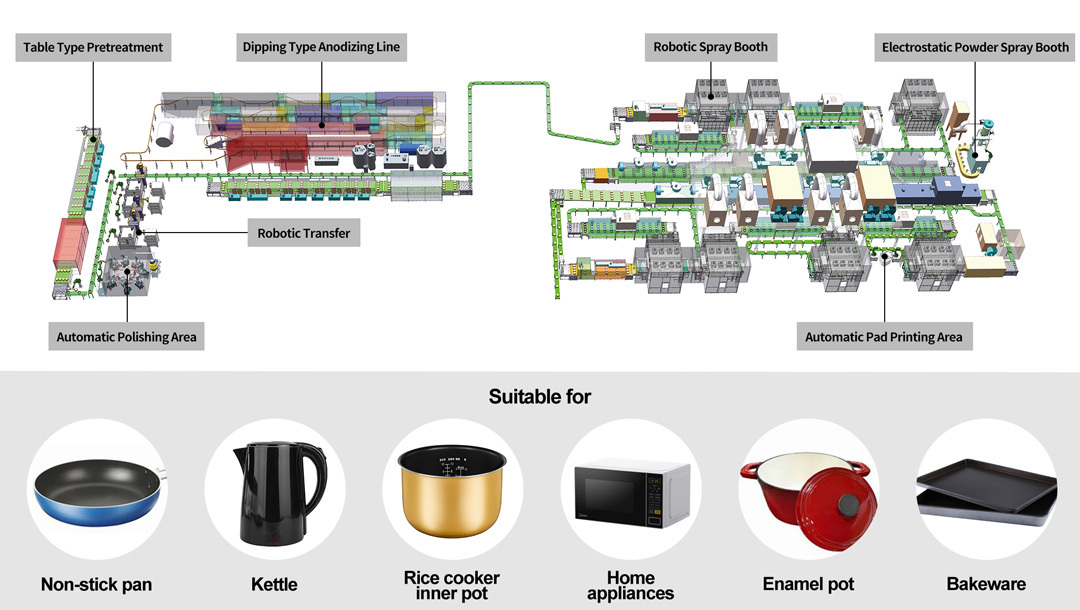

Pretreatment Equipment for Cookware

The pretreatment equipment integrated into the non-stick pan painting line is crucial for ensuring optimal adhesion of the non-stick coating. Before the application of the coating, cookware surfaces are thoroughly cleaned, degreased, and pre-treated to remove any contaminants, oil residues, and oxidation. This process enhances the bonding strength between the cookware surface and the coating, ensuring long-term durability and resistance to wear and tear. The pretreatment system uses advanced washing, etching, and drying technologies, creating the ideal surface conditions for the subsequent application of the non-stick coating. As a result, the cookware achieves a superior finish and better performance over its lifespan.

Aluminum Pot Coating Line

The aluminum pot coating line is specifically designed for the coating of aluminum cookware, such as pots and pans. This specialized line focuses on applying high-performance coatings that enhance the aesthetics and functionality of aluminum cookware. It can accommodate various types of coatings, including non-stick layers, anodized finishes, and decorative coatings. The aluminum pot coating line features precise application systems, ensuring even and flawless coating distribution. Additionally, this line is designed for high throughput and can handle large volumes of cookware, making it an ideal solution for manufacturers looking to optimize production efficiency while maintaining high-quality standards.

Efficiency and Quality Control in Coating Processes

The AttractiveChina non-stick pan painting line and aluminum pot coating line offer significant advantages in terms of both efficiency and quality control. These automated systems reduce the need for manual labor, ensuring consistent results across large production runs. By employing advanced technologies such as robotic coating application, precise temperature control, and curing techniques, the lines guarantee a high level of accuracy and finish quality. The use of environmentally-friendly materials and efficient coating processes further reduces operational costs and waste. The systems are equipped with real-time monitoring and quality control checks, ensuring that every piece of cookware meets the required standards before leaving the production line. This combination of innovation, efficiency, and quality control makes the AttractiveChina coating lines a perfect fit for modern cookware manufacturers.

Technological Process

-

Workpiece: Non-stick pan,kettle,rice cooker inner pot,home appliances,enamel pot,bakeware, etc. Workpiece material: Aluminum alloy, composite material (stainless steel, aluminum alloy, copper, etc.) Work system: 300 days/year; 20H/day; equipment utilization rate: 85% Spray booth temperature: 18~26°C Spray room humidity: 45~75%RH Spraying method: Fixed gun/robot Workpiece size: Ф130~300 mm*160H Production output: 800 pieces/hour Power: 380V 3φ 50 Hz Compressed air: Pressure≥0.7MPa±5% oil<0.01mg/m³ solid <1.00mg/m³ dew point 0.6Mpa -20℃ Natural gas: Standard pressure is medium pressure 80kPa Tap water: Pressure≥1.5Kg/㎝2 Heating energy: Electricity, natural gas Note: Above data for reference only, the actual data will be calculated according to customer require -

Brand Name Attractivechina Dimension(L*W*H) Customized Design Place of Origin Guangdong, China Advantage High-efficiency,environmental-protection Production Capacity Depending on customer needs After-sales Service Provided Engineers available to service machinery overseas Product certificate EAC/CE,ISO14001,ISO45001,1SO9001

Related Products