Related News

23

2024

-

12

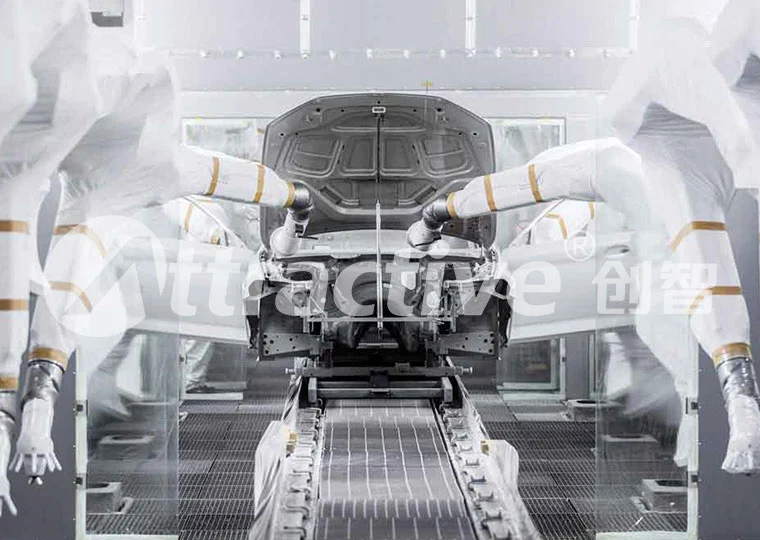

Digital Transformation of Coating Lines: Reshaping the Future of Industrial Production

Author:

Chuangzhi Coating

In today's rapidly developing digital age, all walks of life are undergoing unprecedented changes. As an important part of the manufacturing industry, coating lines are no exception. The digital transformation of coating lines is not only an innovation of traditional production methods, but also a comprehensive upgrade of production efficiency, quality control and sustainable development. This article will explore the background, significance, challenges and implementation paths of the digital transformation of coating lines, aiming to provide valuable reference for corporate decision makers.

Ⅰ. Background of digital transformation of coating lines

With the advancement of science and technology and the diversification of consumer demand, traditional spray coating lines face many challenges. Problems such as low production efficiency, serious waste of resources, and unstable quality control are becoming increasingly prominent. At the same time, the rapid development of digital technologies such as big data, cloud computing, and the Internet of Things has provided strong technical support for the digital transformation of coating lines. These technologies can realize real-time monitoring, intelligent analysis and optimization of the production process, thereby greatly improving production efficiency and product quality.

Ⅱ. The significance of digital transformation of coating lines

1. Improve production efficiency: Through digital technology, painting lines can achieve automated and intelligent production, reduce manual intervention, and improve production efficiency. At the same time, digital technology can also optimize the production process, reduce waiting time and waste in the production process, and further improve overall production efficiency.

2. Improve product quality: Digital technology can achieve precise control of the coating process to ensure that each process meets quality standards. In addition, through data analysis, abnormal problems in the production process can be discovered in time, and corresponding measures can be taken to correct them, thereby avoiding the occurrence of quality problems.

3. Reduce operating costs: Digital transformation helps companies achieve refined management and reduce operating costs. For example, by optimizing the production process, the waste of raw materials and energy can be reduced; through intelligent monitoring, equipment failures can be discovered and repaired in time to avoid losses caused by equipment downtime.

4. Promote sustainable development: Digital transformation helps companies achieve green production. By optimizing the coating process and reducing waste emissions, the impact on the environment can be reduced. At the same time, digital technology can also provide companies with solutions such as energy management and carbon emission monitoring to help companies achieve sustainable development goals.

Ⅲ. Challenges of digital transformation of coating lines

Although digital transformation has brought many benefits to spraying lines, it also faces many challenges during implementation. For example, enterprises need to invest a lot of money in technology upgrades and talent training; technical bottlenecks and security issues may be encountered during the digital transformation process; in addition, employees' acceptance and adaptability to new technologies are also one of the key factors affecting the success of digital transformation.

IV. Implementation path of digital transformation of coating lines

In order to successfully achieve the digital transformation of coating lines, enterprises need to take the following measures:

1. Formulate a clear transformation strategy: Enterprises should formulate clear digital transformation strategies and goals based on their actual conditions and development needs.

2. Strengthen technology research and development and talent training: Enterprises should increase investment in technology research and development to cultivate a team of talents with digital skills and literacy.

3. Optimize production processes and management models: Enterprises should use digital technology to optimize production processes and management models to improve production efficiency and product quality.

4. Strengthen safety management and risk control: Enterprises should establish a sound safety management system and risk control mechanism to ensure safety and stability during the digital transformation process.

5. Promote employee participation and cultural construction: Enterprises should actively promote employees to participate in the digital transformation process and create a positive corporate culture atmosphere.

In short, the digital transformation of coating lines is an inevitable trend in the development of the manufacturing industry. Enterprises should actively respond to challenges, seize opportunities, and achieve comprehensive improvement in production efficiency, product quality and operating costs through digital transformation, laying a solid foundation for the sustainable development of enterprises. Attractivechina, a professional coating line equipment manufacturer, will take you to explore more coating mysteries!