Related News

21

2025

-

01

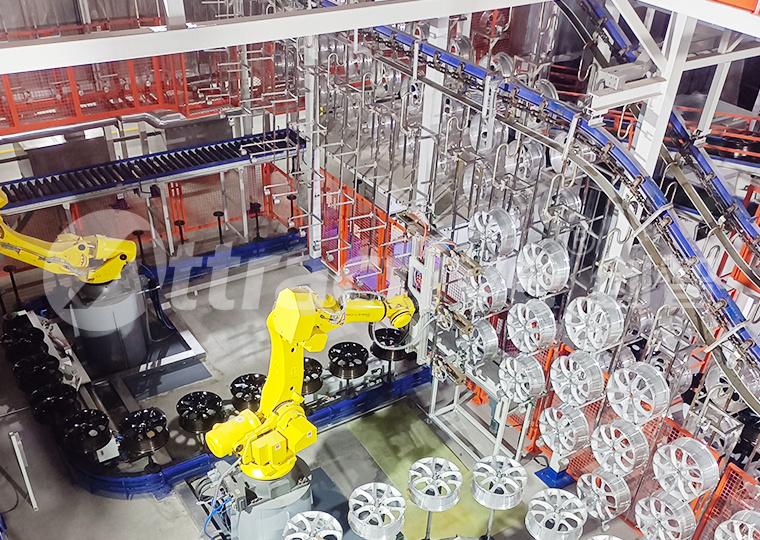

Digital Coating Line: Leading The Coating Industry Towards An Efficient And Sustainable Future

Author:

Chuangzhi Coating

In today's era of rapid digital development, all walks of life are actively exploring the path of digital transformation in order to improve production efficiency, optimize product quality and reduce operating costs. The coating industry, as an important part of the manufacturing industry, is also facing an urgent need for digital transformation. The emergence of digital coating lines has not only brought revolutionary changes to the coating industry, but also pointed out the direction for its future development.

In the production process, traditional coating lines often face multiple challenges such as low efficiency, high energy consumption and serious environmental pollution. These problems not only restrict the development of the coating industry, but also pose a threat to its position in market competition. However, with the continuous maturity and widespread application of digital technology, the coating industry has finally ushered in a good opportunity for transformation and upgrading. Digital coating lines are an important product of this transformation process.

The core of the digital coating line lies in its advanced automatic control system. This system achieves precise control of the coating process by integrating advanced sensors, actuators and controllers. It can monitor the operating status of the coating equipment in real time, and automatically adjust various parameters such as paint flow, spraying speed, drying temperature, etc. according to production needs, so as to ensure that the coating process is always in the best state. This precise control not only improves production efficiency, but also significantly improves product quality, allowing the coating line to produce more uniform and consistent products.

In addition to the automated control system, the digital coating line also widely uses intelligent sensor technology. These sensors can sense environmental changes and coating conditions such as temperature, humidity, and coating viscosity in real time, and feed this information back to the control system. The control system makes corresponding adjustments based on this information to ensure the uniformity and consistency of the coating. This intelligent perception and adjustment mechanism enables the coating line to respond to various production environments more flexibly, thereby improving production efficiency and product quality.

Data analysis technology is another highlight of the digital coating line. By collecting, sorting and analyzing the massive data generated during the coating process, enterprises can have a deeper understanding of the operating status of the coating line, discover potential problems and hidden dangers, and formulate optimization measures accordingly. This data-driven management model not only improves the operating efficiency of the coating line, but also provides a scientific basis for the company's decision-making.

In terms of environmental protection and sustainable development, digital coating lines also perform well. By adopting low-energy, low-pollution coating equipment and processes, and implementing strict waste treatment measures, digital coating lines not only improve economic benefits, but also significantly reduce the negative impact on the environment. This green production method not only complies with the country's environmental protection policies, but also meets consumers' demand for environmentally friendly products.

Looking to the future, digital coating lines will continue to develop in the direction of intelligence, flexibility and greening. With the continuous integration of cutting-edge technologies such as artificial intelligence and the Internet of Things, the automation and intelligence level of coating lines will be further improved. For example, by introducing machine vision technology, coating lines can realize real-time detection and feedback of coating quality, thereby further improving product quality. At the same time, in order to meet the increasingly diversified needs of the market, coating lines will also have stronger flexible production capabilities and can quickly adapt to the coating needs of different products.

In summary, the emergence of digital painting lines is an inevitable trend in the development of the coating industry. It not only solves many problems existing in traditional coating lines, but also brings new development opportunities to the coating industry. We have reason to believe that in the near future, digital coating lines will become the mainstream production method of the coating industry. It will lead the coating industry towards a more efficient, environmentally friendly and sustainable future, and inject new vitality into the transformation, upgrading and high-quality development of the manufacturing industry.