Related News

24

2025

-

03

Maximizing Efficiency with Wheel Hub Coating Lines: A Comprehensive Overview

Author:

Chuangzhi Coating

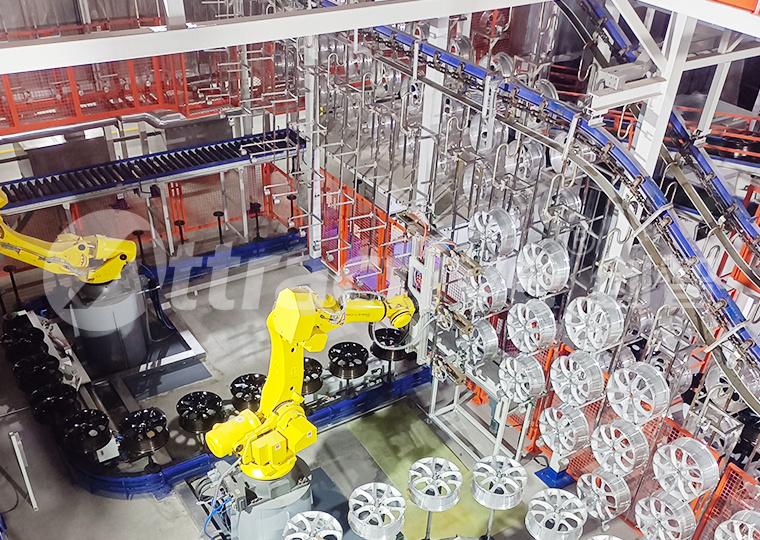

Wheel hub coating lines play a vital role in the automotive manufacturing sector, specifically in the application of protective coatings to wheel hubs. These lines are designed to enhance the durability and aesthetics of wheel hubs, ensuring they withstand harsh environmental conditions and mechanical stresses. Utilizing advanced coating technologies, these production lines not only improve product quality but also boost operational efficiency.

One of the key components of a wheel hub coating line is the pre-treatment process. This stage typically involves cleaning and preparing the wheel hubs to ensure optimal adhesion of the coating. Techniques such as shot blasting, phosphating, or chemical cleaning may be employed to achieve a clean surface. A well-executed pre-treatment process is crucial, as it lays the foundation for the quality of the final finish.

The primary coating methods used in wheel hub coating lines include electrostatic spray, powder coating, and liquid painting. Electrostatic spray coating utilizes a charged spray system that attracts charged paint particles to grounded wheel hub surfaces, resulting in an even and efficient application. Powder coating, on the other hand, involves applying dry powder that is then cured under heat, creating a strong, durable finish. Liquid painting, while less common in industrial settings, may still be applicable under specific circumstances.

After the application of the coating, the curing phase is critical. This process ensures that the coating achieves its full hardness and adhesion properties. Different curing methods, such as infrared curing or convection ovens, can be utilized depending on the type of coating material and the desired properties of the final product.

Efficiency in a wheel hub coating line can be significantly affected by several factors, including line speed, equipment layout, and operator training. Implementing lean manufacturing principles can help streamline operations, reduce waste, and improve productivity. Regular maintenance of the coating equipment is also essential to prevent downtime and ensure consistent quality.

Moreover, technological advancements in automation and control systems have revolutionized wheel hub coating lines. Automation not only enhances precision and repeatability in coating applications but also allows for real-time monitoring of the process, enabling quick adjustments to maintain quality standards.

To sum up, wheel hub coating lines are integral to the production of high-quality automotive components. By focusing on proper pre-treatment, selecting appropriate coating methods, and maintaining efficient operations, manufacturers can significantly improve their productivity and product quality. Understanding these elements will empower professionals in the industry to make informed decisions and drive improvements in their coating processes.