All categories

Related News

10

2025

-

09

How to Achieve Perfect Coverage in Wheel Coating with Electrostatic Spray?

Author:

Chuangzhi Coating

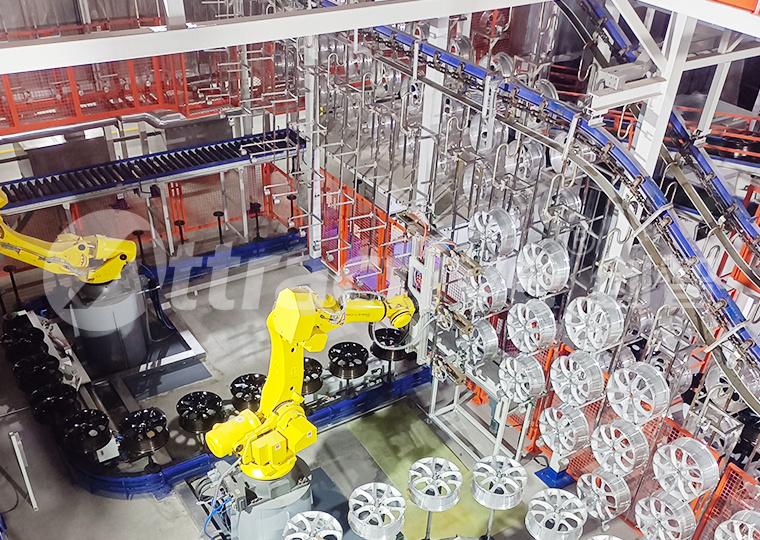

The coating coverage of automotive wheels directly determines the product's appearance and protective performance - missed coating in complex structures such as bolt hole inner walls, spoke roots, and wheel grooves will lead to local corrosion and rust, shortening the service life. Electrostatic spray, with its "electrostatic adsorption" characteristic (paint utilization rate ≥90%), enables paint particles to actively adhere to the workpiece surface, making it particularly suitable for solving the coverage problem of wheel's special-shaped structures. As a professional manufacturer of coating line equipment, we help enterprises achieve 100% perfect coverage in wheel coating through customized electrostatic spray equipment, precise process parameters and intelligent control.

1. Core Principle of Achieving Perfect Coverage with Electrostatic Spray

The "adsorption effect" of electrostatic spray is the key to solving coverage problems, and its core lies in the three-step process of "charge application - electric field adsorption - uniform deposition":

- Charge Application: Through friction or a high-voltage electrostatic generator (voltage 60-100kV), paint particles are negatively charged (charge density ≥1×10⁻⁶C/kg), forming a uniform group of charged particles;

- Electric Field Adsorption: The wheel is grounded to form a positive electrode, and an electrostatic field is generated between the wheel and the negatively charged paint particles. The particles move along the electric field lines under the action of electric field force, actively moving towards the wheel surface (including depressions and dead corners) to overcome paint loss caused by gravity;

- Uniform Deposition: After the charged particles reach the wheel surface, due to the repulsion of like charges, they automatically disperse and deposit uniformly, avoiding local accumulation and forming a coating with consistent thickness (deviation ≤±5μm). It is particularly suitable for covering narrow areas such as spoke gaps (width ≥3mm) and bolt holes (diameter ≥8mm).

Compared with traditional air spraying, electrostatic spray improves the coverage efficiency of complex wheel structures by 40%, and the missed coating rate drops from 15% to below 0.5%, making it the core technical support for achieving perfect coverage.

2. Customized Electrostatic Spray Equipment Configuration: Adapting to Wheel Structure

To achieve perfect coverage, it is necessary to configure special electrostatic spray equipment according to the "multi-spoke, multi-dead corner" structural characteristics of wheels:

a. Electrostatic Spray Gun: Precise Control of Paint Particles

- Gun Type Selection: The main spray gun adopts a "high-voltage electrostatic airless spray gun" (atomization pressure 15-20MPa), with the atomization particle size controlled at 10-20μm to ensure that particles can penetrate into bolt holes (depth ≥15mm); for the rounded corner areas of spoke roots (radius ≤5mm), a "micro electrostatic spray gun" (nozzle diameter 0.8-1.2mm) is equipped, and the paint output is reduced to 5-10g/min to avoid paint accumulation;

- Charge Control: The spray gun has a built-in "intelligent voltage adjustment module" that automatically switches the voltage according to the wheel part - high voltage of 80-100kV is used for flat areas (such as the front of the wheel) to enhance adsorption; it is reduced to 60-70kV for concave areas (such as spoke gaps) to prevent paint rebound caused by excessive charge and improve coverage uniformity.

b. Conveying and Positioning System: Ensuring No Dead Corner Spraying

- Rotary Conveying: A "suspended servo rotation mechanism" is used to drive the wheel to rotate at a constant speed of 360° (rotating speed 10-15r/min), combined with linear conveying (speed 1-2m/min), allowing the spray gun to cover the wheel surface from multiple angles;

- Visual Positioning: A "3D visual scanning system" (accuracy ±0.1mm) is set up before the spraying station to automatically identify the wheel model (14-22 inches) and the number of spokes (5-10 spokes), generate a customized spraying path, and ensure that the distance between the spray gun and each part of the wheel is constant (250-300mm), avoiding coverage unevenness caused by distance deviation.

c. Auxiliary Spraying Unit: Solving Extreme Dead Corners

For the inner wall of bolt holes that are difficult to cover with traditional spray guns, a "built-in electrostatic spray rod" is configured - the rod diameter is ≤5mm, which can penetrate 10-20mm into the hole. The rod end is equipped with a micro nozzle (360° angle), and through high-voltage electrostatic (50-60kV), the paint particles are evenly deposited on the inner wall of the hole, with a film thickness of 60-80μm, consistent with the outer wall coating thickness, completely solving the problem of bolt hole missed coating.

3. Process Parameter Optimization: Ensuring Stable Coverage Quality

The perfect coverage of electrostatic spray needs to be achieved through refined parameter adjustment, and the core parameters include:

a. Paint Characteristic Adaptation

- Viscosity Control: Stabilize the paint viscosity at 20-30s (Tu-4 cup, 25℃), and through the heating and heat preservation device (temperature ±2℃) of the paint supply system, prevent poor atomization caused by viscosity fluctuation;

- Conductivity Adjustment: Add 0.1-0.3% conductive agent to the paint to maintain the paint conductivity at 50-100μS/cm, ensuring that charges can be evenly applied to the paint particles and avoiding insufficient adsorption caused by low conductivity.

b. Spraying Environment Control

- Humidity Management: The humidity of the spray booth is controlled at 50-60% (deviation ±5%). Excessive humidity will cause charge loss of paint particles and reduce adsorption; too low humidity is prone to electrostatic dust accumulation, affecting coverage quality, which needs to be adjusted in real time through a constant temperature and humidity system;

- Airflow Control: "Negative pressure directional airflow" (wind speed 0.3-0.5m/s) is adopted, flowing directionally from the spray gun to the exhaust port, avoiding paint particle deviation caused by disordered airflow and ensuring that particles adhere to the wheel surface accurately.

c. Multi-Coat Spraying Process

Adopt a two-step electrostatic spraying process of "primer + topcoat": the primer spraying focuses on coverage, using low-viscosity paint (20-25s) and medium voltage (70-80kV) to fill the fine depressions on the wheel surface; the topcoat spraying focuses on appearance, using high-viscosity paint (25-30s) and high voltage (80-90kV) to ensure a smooth and bright coating. The total film thickness of the two sprays reaches 100-120μm, with no missing coverage.

4. Quality Inspection and Feedback: Ensuring Coverage Compliance

Establish a dual guarantee system of "online inspection + offline sampling inspection" to verify coverage quality:

- Online Inspection: Set up a "film thickness scanning system" after spraying, and perform 100% inspection on the entire wheel surface through a laser thickness gauge (accuracy ±1μm) to generate a film thickness distribution heat map. If the film thickness in a certain area is lower than 50μm (qualified lower limit), the system automatically alarms and triggers rework;

- Offline Sampling Inspection: Extract 3-5 wheels per batch for "salt spray test" (ASTM B117 standard, 500 hours) and "adhesion test" (cross-cut method, grade 0), observe whether there is local corrosion or coating peeling, and verify the protective performance of the covered area;

- Parameter Feedback: Upload the inspection data to the MES system in real time. If a certain part frequently has coverage problems, the system automatically optimizes the corresponding parameters (such as adjusting the spray gun voltage and rotation speed), forming a closed loop of "inspection - optimization - re-inspection" to continuously improve coverage stability.

Application Case: Coverage Improvement Effect of a Wheel Enterprise

After a certain aluminum alloy wheel enterprise introduced this electrostatic spray solution, the core indicators improved significantly: the wheel missed coating rate dropped from 8% to below 0.2%, and the coating coverage rate of the bolt hole inner wall reached 100%; the paint utilization rate increased from 75% to 92%, saving more than 1.8 million yuan in annual material costs; the product appearance qualification rate increased from 88% to 99.5%, successfully entering the high-end automotive supply chain, with orders increasing by 35%.

Conclusion

Achieving perfect coverage in wheel coating with electrostatic spray lies in "equipment customization, parameter refinement, and inspection closed-loop" - solving the coverage problem of complex structures through electrostatic spray guns adapted to wheel structures, precise process control, and strict quality inspection. As a manufacturer of coating line equipment, we can provide a full-process solution from equipment configuration to process commissioning according to the enterprise's wheel model and production capacity needs, helping enterprises achieve "zero missed coating, high quality" wheel coating production.

SEO: