Related News

28

2026

-

01

What is Complete Coating Line Equipment?

Author:

Chuangzhi Coating

In today's manufacturing landscape driven by the pursuit of high quality, efficiency, and sustainable development, Complete Coating Line Equipment has transcended the scope of individual machines to become a complex systems engineering project integrating mechanical engineering, chemical processes, automation control, and intelligent management. It is not only the physical carrier that imparts products with aesthetic appeal, long-lasting corrosion protection, and specific functionalities but also the core infrastructure enabling companies to optimize production flow, ensure quality consistency, achieve green manufacturing, and control costs. This article delves into the systematic composition, core value, and key selection criteria of a modern, high-efficiency Complete Coating Line Equipment, outlining the complete picture of this manufacturing cornerstone.

I. What is "Complete Coating Line Equipment"? Systems Thinking Beyond Single-Machine Integration

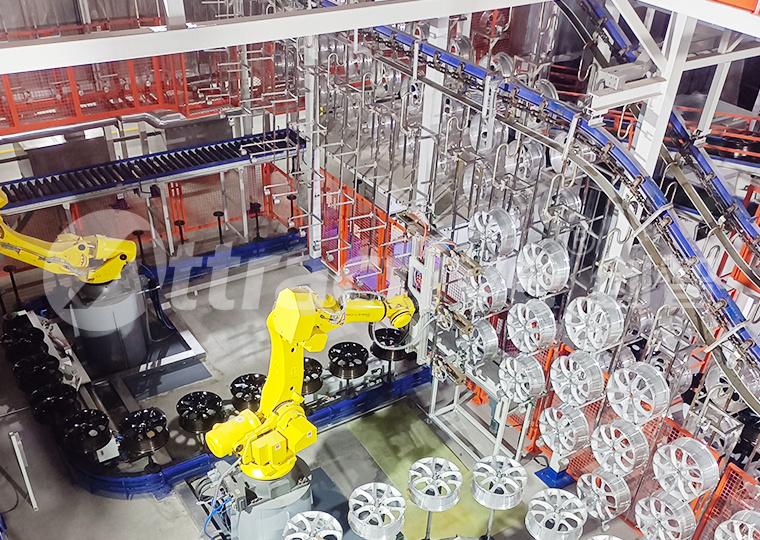

The essence of "Complete" lies in systematic design, coherence, and deliverability. A set of Complete Coating Line Equipment is not a simple assembly of isolated station equipment but a continuously integrated production system designed holistically according to specific workpieces (e.g., metal structures, auto bodies, appliance housings, profiles), coating types (e.g., liquid paint, powder coating, electrocoat), and process requirements. It achieves fully automated transfer and precise control throughout the entire process—from loading, pre-treatment, coating application, curing/drying, unloading to exhaust gas and wastewater treatment—ultimately delivering finished products with predetermined coating performance through stable, reproducible processes.

Its core objective is to eliminate "islands" between production stages, ensuring precise execution of process parameters at every step, thereby fundamentally guaranteeing the excellence and stability of the final coating quality. Therefore, an outstanding set of Complete Coating Line Equipment is, in essence, a fully functional, highly coordinated "coating plant."

II. Core Module Analysis: The Four Pillars of a Complete Coating Line

A typical Complete Coating Line Equipment is usually modularly constructed from the following key subsystems, which are interlinked to form an efficient production loop:

- Automated Logistics & Pre-treatment System

This is the "foundation work" for coating quality. The system begins with intelligent loading and conveying equipment (e.g., overhead conveyors, floor conveyors, shuttle systems) to ensure smooth, orderly workpiece flow. The pre-treatment section is critical, typically involving multi-stage cleaning, degreasing, surface conditioning, phosphating (or environmentally friendly alternatives like silane/zirconium-based treatments), and drying. Its function is to thoroughly remove oils, rust, and contaminants from the workpiece surface and form a uniform, dense conversion coating, providing a robust foundation for adhesion. The integrity of this system directly determines the coating's lifespan.

- Precision Coating Application & Circulation System

This is the "heart" of the production line. Depending on the process, it can integrate various coating technologies:- Spraying System: Includes high-efficiency electrostatic bells/guns, robotic spraying stations, precise paint supply and mixing systems, temperature-and-humidity-controlled spray booths, and high-recovery powder/overspray recovery units.

- Dip Coating/Electrocoating System: Includes electrocoat tanks, circulation filtration systems, anode systems, ultrafiltration units, and subsequent rinse systems, primarily used for providing superior anti-corrosion primers.

The core of this module is to achieve efficient, uniform, repeatable coating application while maximizing material utilization.

- High-Efficiency Curing & Drying System

This is the "furnace" where the coating acquires its final properties. The system includes ovens and curing ovens (e.g., gas-fired, electric, infrared, UV) designed for different process stages. Modern curing systems emphasize efficient recycling of thermal energy, temperature uniformity within the oven (within ±5°C), and precise control of the heating curve. This ensures the coating is fully cross-linked and cured to achieve the designed hardness, gloss, and durability while minimizing energy consumption to the greatest extent.

- Environmental Treatment & Intelligent Control System

This is the "brain" for the line's green and intelligent operations. The Environmental System integrates exhaust gas (e.g., RTO, RCO incineration units) and wastewater treatment equipment, ensuring compliance with the strictest environmental regulations. The Intelligent Control System (based on PLC, SCADA, or MES) is the nerve center of the entire Complete Coating Line Equipment. It monitors and coordinates the operation of all equipment, collects and analyzes process data (e.g., temperature, pressure, film thickness), enabling process visualization, fault warning, and quality traceability. It is the guarantee of production stability and continuous optimization.

III. The Strategic Value of Investing in Complete Coating Line Equipment

Choosing to invest in an Integrated Coating System, rather than procuring equipment piecemeal, brings multi-dimensional strategic advantages to an enterprise:

- Exceptional Quality Consistency: Integrated design eliminates fluctuations at process interfaces, and automated control removes human variability, ensuring batch-to-batch coating quality with zero deviation.

- Significantly Improved Production Efficiency: Continuous automated operation provides stable cycle times, drastically reduces workpiece handling time, significantly increases output capacity, and meets large-scale delivery demands.

- Substantial Reduction in Total Cost of Ownership: High material utilization reduces coating waste; centralized energy management lowers unit consumption; reduces dependence on highly skilled operators; low defect rates save rework costs.

- Achieves Green Compliance & Sustainability: Built-in end-of-pipe treatment systems ensure environmental standards are met, avoiding regulatory risks; energy-efficient designs reduce carbon footprint and enhance corporate social image.

- Empowers Smart Manufacturing & Data-Driven Decisions: As part of a digital factory, the vast amount of data generated by the production line can be used for predictive maintenance, process optimization, and advanced analytics, supporting corporate decision-making.

IV. Path to Success: How to Select and Implement a Turnkey Coating Solution

Facing the complexity of a Complete Coating Line Equipment project, selecting a supplier with profound process knowledge and strong engineering capabilities is paramount. An ideal partner should be able to provide a genuine "Turnkey Coating Solution", with services covering:

- In-depth Process Analysis: Tailored design based on your product, capacity, and coating materials.

- Integrated Engineering Design & Manufacturing: Ensuring seamless compatibility of all subsystems.

- Professional Installation & Commissioning: Precise assembly and process parameter setting at your site.

- Comprehensive Training & Ongoing Support: Transferring operational and maintenance knowledge to your team and providing long-term technical support.

When evaluating suppliers, focus on their successful case studies in relevant industries, the advancement of their core technologies (e.g., energy saving, recovery rates), the intelligence level of their control systems, and their project management professionalism.

V. Conclusion

In today's manufacturing competition increasingly focused on "quality," "efficiency," and "sustainability," a technologically advanced, reliably operating Complete Coating Line Equipment has evolved from a significant capital investment into a strategic asset that determines a company's product competitiveness, brand image, and operational profitability. It represents the triumph of systems thinking over fragmented operations, the replacement of experience-dependence with precise control, and the upgrade of traditional manufacturing to green intelligence. For enterprises determined to build a lasting advantage in high-end manufacturing, investing in and optimizing their Complete Coating Line Equipment is to solidify the cornerstone for future development—arming their products with "armor" that combines aesthetics and functionality to seize the initiative in the fierce market competition.

SEO: