Related News

24

2019

-

09

Influence of humidity on waterborne coating construction and solutions

Author:

Chuangzhi Coating

We all know that the requirements for environmental humidity in waterborne coatings are significantly higher than those of solvent-based coatings. This is also the difference between water-based coatings and solvent-based coatings, which are reflected in the following two aspects:

1. In the environment with high humidity (humidity greater than 85%), it is prone to sag, loss of light, slow surface drying, soft paint film and other paint film defects;

2, under low humidity conditions (humidity is less than 35%), it is easy to appear pinholes, dry hair, large orange peel, reduced surface fullness and other disadvantages.

For the above problems, the solutions that can be solved at the construction site include:

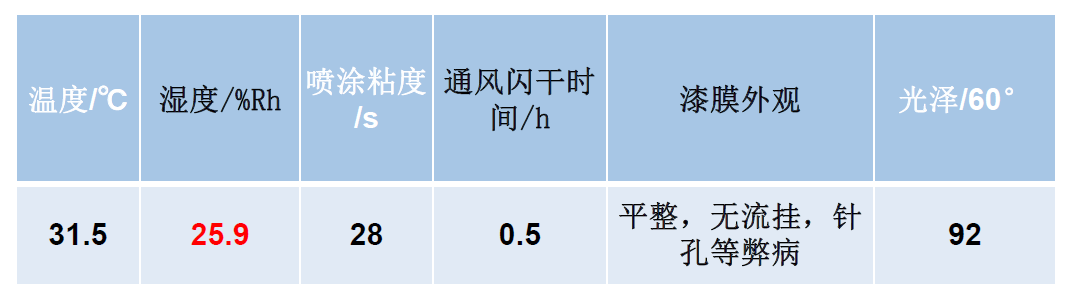

1. Use air spray gun preferentially under high humidity conditions, and increase the construction viscosity by 5-10s. Adjust the spray gun parameters during construction, reduce the spray gun flow, increase the spray pressure, increase the atomization, and extend the flow between the two sprays. Flat flashing time, prolong the ventilation time after spraying, should not be applied when the ambient humidity is high for a long time without auxiliary drier equipment; when the humidity is low, the opposite is true.

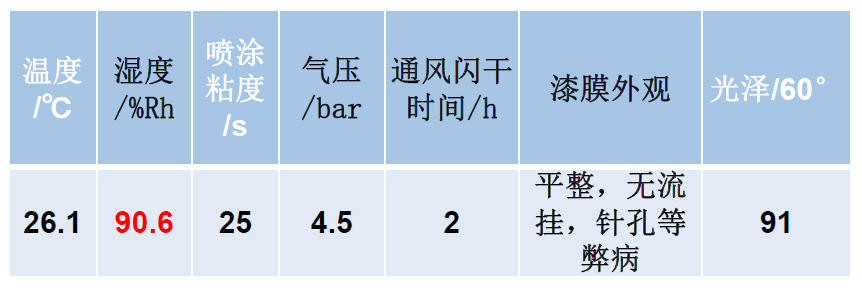

2, under low humidity conditions, the construction viscosity is lowered by 3-5s. Adjust the parameters of the spray gun during construction, reduce the flow of the spray gun, reduce the spray pressure, and shorten the gun distance by 5-10cm. It is worth noting that under low humidity conditions, no The air spray effect is better.

In addition, some water-based paint manufacturers on the market say that the use of water-based paint requires constant temperature and humidity environment? In fact, it is not necessarily required. As long as the temperature is ≥10 °C and the humidity is ≤80% (±5), it can be used. When the temperature is low or the humidity is high, the drying speed will decrease, and vice versa. Of course, it can achieve constant temperature and humidity, which is an ideal water-based paint application environment.

However, the water-temperature paint workshop with constant temperature and humidity is not easy to do. First, water-based paints require a large amount of moisture to be discharged during the coating process. Secondly, the water used for spraying the curtain cabinet will also release a large amount of water.

The point is that the painting workshop is not a sealed environment. Because of the discharge of the paint, the air flow is very large, and the constant temperature and humidity are difficult to maintain. Therefore, constant temperature and humidity treatment requires a lot of energy consumption, which is not only difficult but also costly.

The above is about the [humidity on the impact of water-based paint construction and solutions], then, I will introduce you to the key point control information in the construction of water-based paint, welcome to pay attention to our access to updated information! Watch more videos