编号 :

Attractivechina2025080506

UV Coating Machine Spraying Equipment Omega Spray Booth Furniture Coating Line

零售价

市场价

Technology at home and abroad

Quality assurance

Tailored

Original purchase

SEO:

全国客户服务热线 7*24小时:

+86 758-6626158-8063

重量

库存

隐藏域元素占位

- Product Details

- Product Parameters

- Product Properties

-

The AttractiveChina UV coating machine spraying equipment is designed to revolutionize the coating process in various industries, particularly in furniture production and other high-quality manufacturing sectors. This advanced system utilizes UV curing technology, offering a highly efficient, environmentally-friendly alternative to traditional coating methods. The UV coating machine is capable of applying a durable, glossy finish to wood, metal, plastic, and other substrates, enhancing the aesthetic appeal and durability of products. By using UV light to cure the coatings instantly, it significantly reduces processing time, resulting in higher throughput and greater efficiency in production lines.

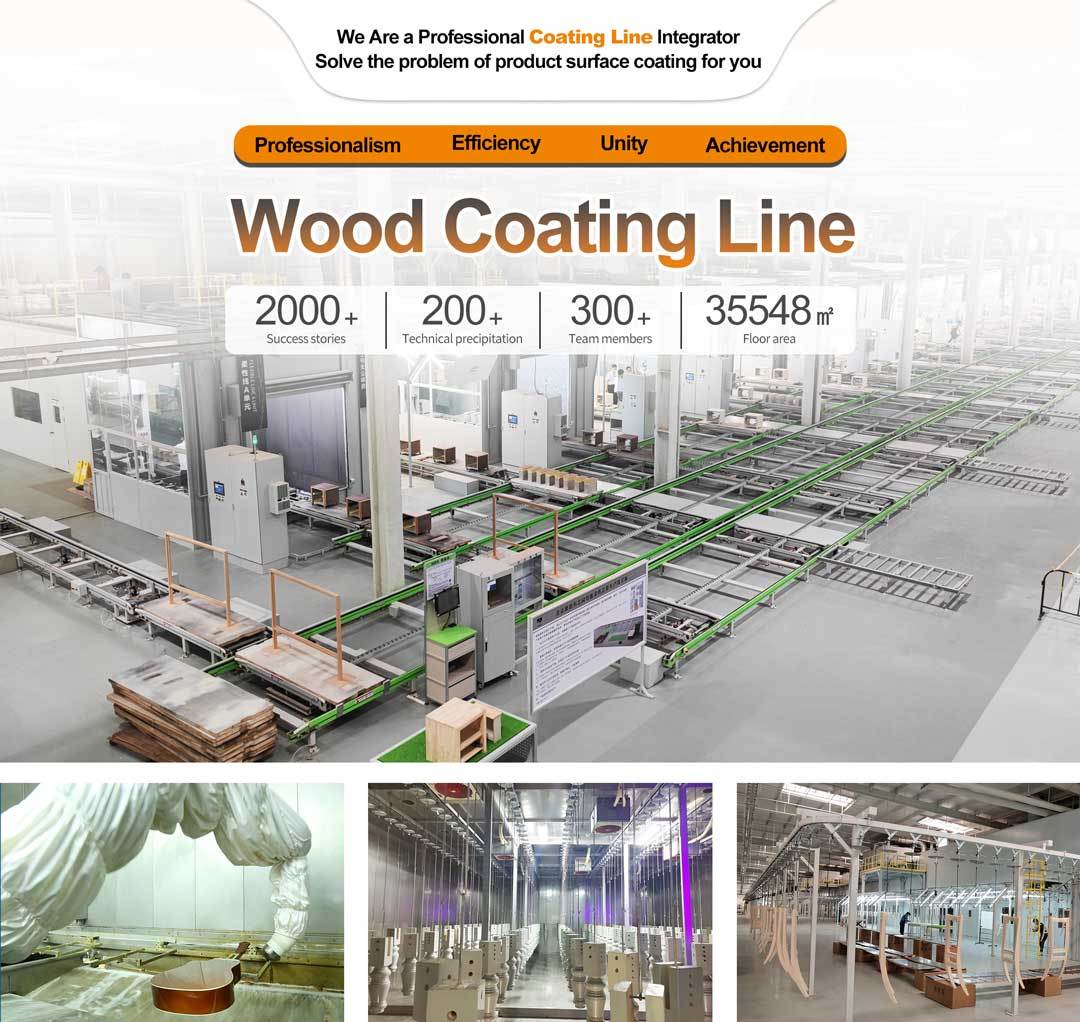

Wood Coating Line

Omega Spray Booth for Furniture Coating

The Omega spray booth is a key component of the coating line, specifically designed for furniture coating applications. It provides a controlled environment for spraying paints, varnishes, and coatings, ensuring that the finish is smooth, even, and free from contaminants. The booth is equipped with advanced air filtration systems to capture overspray and particles, reducing waste and maintaining air quality in the workplace. With its versatile design, the Omega spray booth can accommodate various furniture pieces, ranging from smaller components to large-scale products, while providing a safe and efficient coating process. The booth’s precise airflow and temperature controls contribute to consistent coating results and minimal drying times.

UV Coating Line for Furniture Production

The UV coating line integrated with the UV coating machine and spray booth offers a complete solution for furniture coating. This line is specifically engineered for applying high-quality UV coatings to wood and composite materials, which are commonly used in furniture manufacturing. The UV coatings provide superior scratch resistance, gloss retention, and overall durability, making them ideal for furniture exposed to frequent use. The system is designed for high-speed operations, ensuring that production timelines are met while maintaining excellent finish quality. Additionally, the use of UV light to cure the coatings not only speeds up the process but also reduces energy consumption compared to traditional heat-based curing methods.

Efficiency and Environmental Benefits

The AttractiveChina UV coating machine spraying equipment and associated components like the Omega spray booth and UV coating line contribute significantly to both operational efficiency and environmental sustainability. By eliminating the need for solvents and reducing emissions, the UV coating process helps manufacturers comply with stringent environmental regulations. Moreover, the UV curing technology ensures minimal waste, as the coatings are applied precisely with minimal overspray. This results in cost savings on materials and reduced environmental impact. The automated nature of the coating line further enhances productivity by reducing labor costs and minimizing human error, making it an ideal solution for businesses looking to improve efficiency, reduce costs, and promote sustainability in their operations.

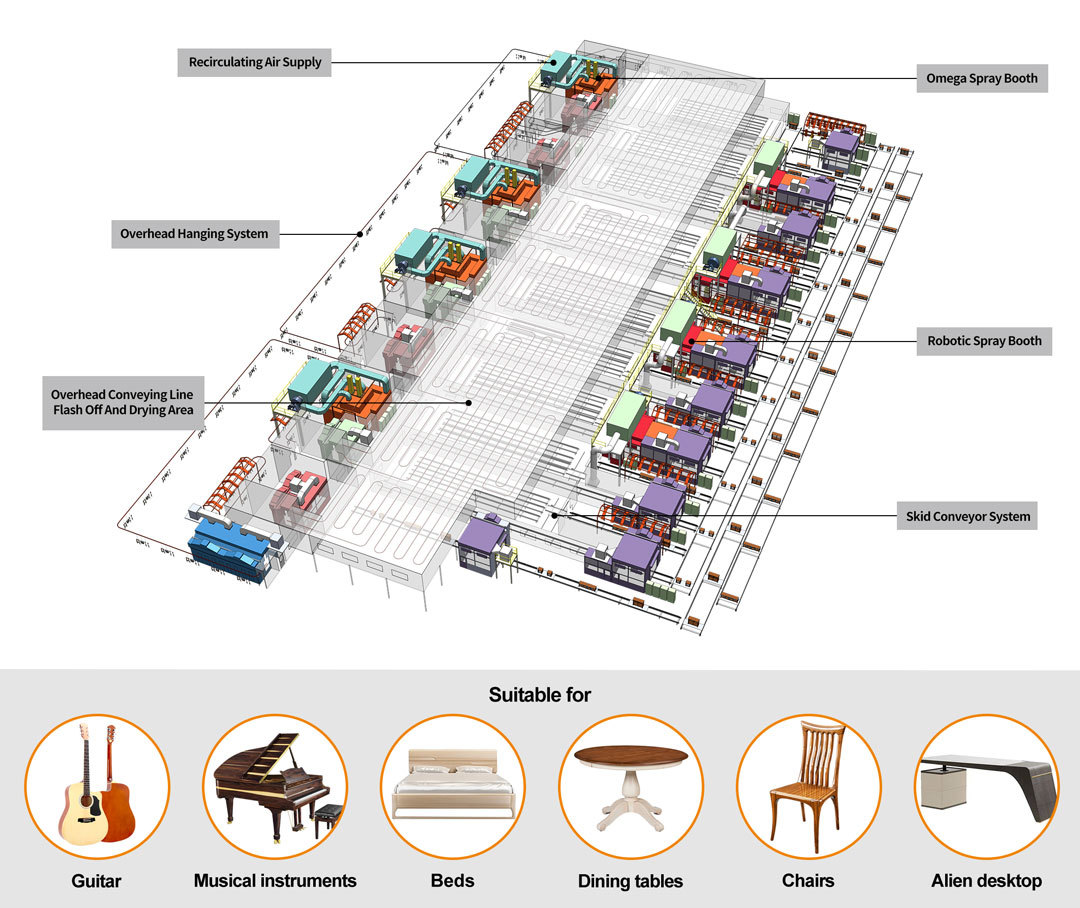

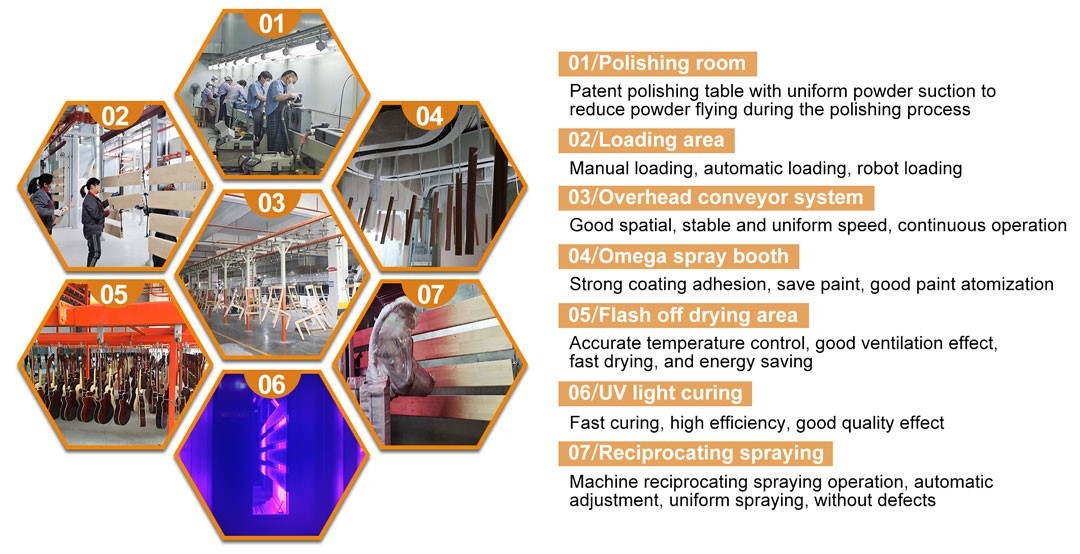

Technological Process

Wood Coating Line

Loading→Primer 1 spraying→Primer 2 spraying→Glue spraying→Wiping→Primer→Dry brush→Two coats of primer→Tint→Top-coat→Inspection area→Finished product drying→Unloading

-

Workpiece: Guitar, musical instruments, beds, dining tables, chairs, alien desktop, etc. Workpiece material: Solid wood, medium fiber board, veneer particleboard Work system: 300 days/year; 20H/day; equipment utilization rate: 85% Spray booth temperature: 18~26°C Spray room humidity: 45~75%RH Spraying method: Artificial/Robotic Tool tray size: L2300 * W800 * H2200mm (reference) Production rhythm: 1.0min-4min/pry (depending on different workpieces) Workpiece weight: 300KG Power: 380V 3φ 50 Hz Compressed air: Pressure≥0.7MPa±5%(Gauge pressure)、oil<0.01mg/m³ 、solid <1.00mg/m³ 、dew point 0.6Mpa -20℃ Natural gas: Standard pressure is medium pressure 80kPa Tap water: Pressure≥1.5Kg/㎝2 Heating energy: Electricity, natural gas Note: Above data for reference only, the actual data will be calculated according to customer require -

Brand Name Attractivechina Dimension(L*W*H) Customized Design Place of Origin Guangdong, China Advantage High-efficiency,environmental-protection Production Capacity Depending on customer needs After-sales Service Provided Engineers available to service machinery overseas Product certificate EAC/CE,ISO14001,ISO45001,1SO9001

Related Products