编号 :

Attractivechina2025080507

Wood Door Electrostatic Painting Production Line UV Coating Paint Spray Line

零售价

市场价

Technology at home and abroad

Quality assurance

Tailored

Original purchase

全国客户服务热线 7*24小时:

+86 758-6626158-8063

重量

库存

隐藏域元素占位

- Product Details

- Product Parameters

- Product Properties

-

The robotic automatic spray painting line represents a significant advancement in industrial automation, offering high precision and efficiency for spray painting applications. This system leverages advanced robotics to automate the painting process, reducing the need for manual labor and ensuring consistent, high-quality results. By utilizing robotic arms equipped with spray nozzles, the system can precisely apply paint coatings to various surfaces, such as automotive parts, machinery, or appliances, with a high degree of accuracy. The automatic nature of the line also ensures repeatability, allowing manufacturers to maintain uniform paint finishes on large production volumes, thereby improving overall product quality and reducing human error.

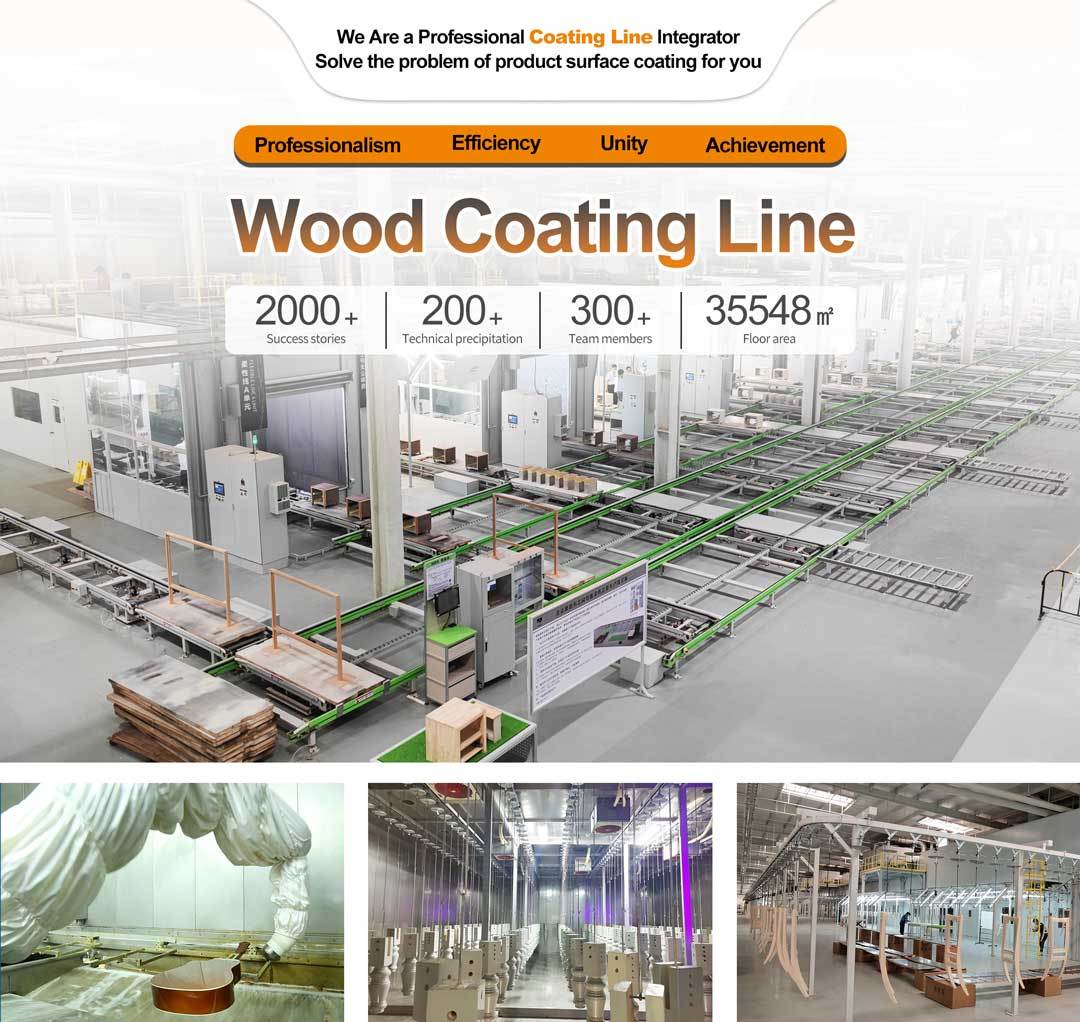

Wood Coating Line

One of the key benefits of the robotic automatic spray painting line is its enhanced efficiency. The robots can work continuously, operating at high speeds while maintaining optimal spray patterns and coverage. This increases throughput in manufacturing environments, helping companies meet tight production schedules. Additionally, the automated system minimizes paint waste by precisely controlling the application amount, reducing overspray and ensuring that only the required amount of paint is used. This not only lowers material costs but also has a positive environmental impact by reducing VOC (volatile organic compound) emissions and waste.

The system is highly adaptable, capable of handling various types of paints and coatings, including water-based, solvent-based, and powder coatings. The robotic arms can be programmed to adjust spraying techniques based on the specific requirements of the object being painted, ensuring even coverage on complex geometries or intricate surfaces. This flexibility is crucial in industries such as automotive manufacturing, furniture production, and electronics, where parts come in different shapes and sizes. The system can also be integrated with advanced vision systems that allow robots to recognize and adjust to different workpieces, ensuring perfect application every time.

In addition to improving painting quality and productivity, the robotic automatic spray painting line offers significant health and safety benefits. By automating the painting process, it minimizes workers' exposure to hazardous chemicals and fumes, creating a safer work environment. The system can be equipped with air filtration systems to capture airborne particles, ensuring compliance with environmental regulations. The combination of automation, precision, and safety makes robotic spray painting lines an invaluable asset for manufacturers looking to improve operational efficiency, product consistency, and workplace safety.

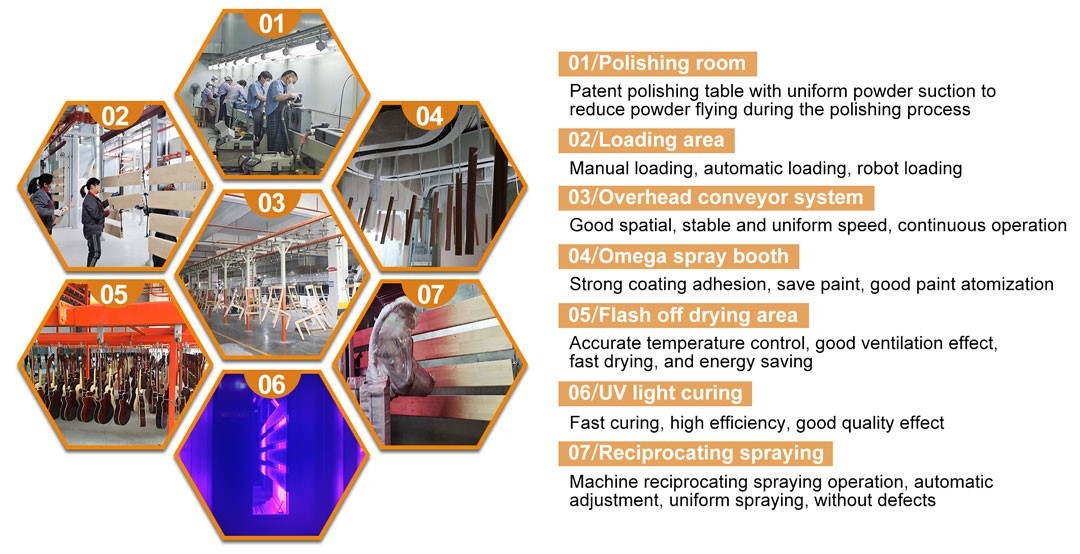

Technological Process

Wood Coating Line

Loading→Primer 1 spraying→Primer 2 spraying→Glue spraying→Wiping→Primer→Dry brush→Two coats of primer→Tint→Top-coat→Inspection area→Finished product drying→Unloading

-

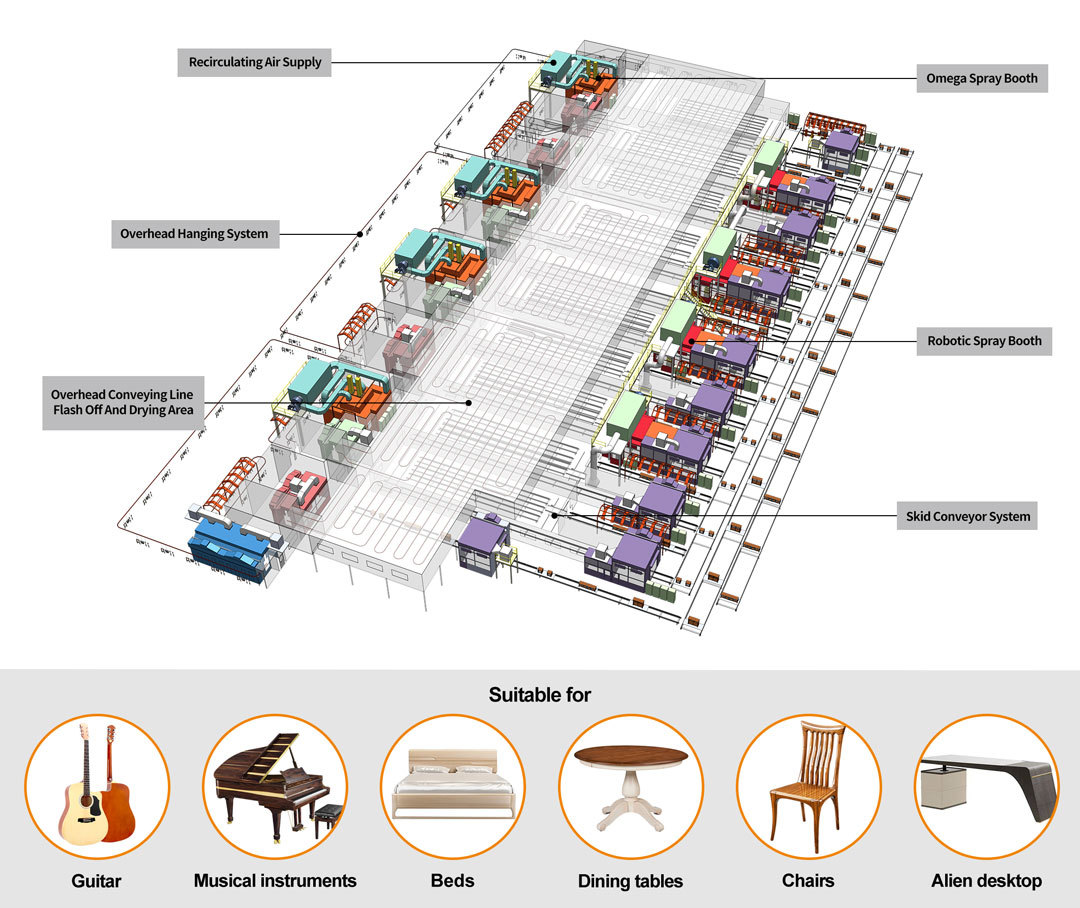

Workpiece: Guitar, musical instruments, beds, dining tables, chairs, alien desktop, etc. Workpiece material: Solid wood, medium fiber board, veneer particleboard Work system: 300 days/year; 20H/day; equipment utilization rate: 85% Spray booth temperature: 18~26°C Spray room humidity: 45~75%RH Spraying method: Artificial/Robotic Tool tray size: L2300 * W800 * H2200mm (reference) Production rhythm: 1.0min-4min/pry (depending on different workpieces) Workpiece weight: 300KG Power: 380V 3φ 50 Hz Compressed air: Pressure≥0.7MPa±5%(Gauge pressure)、oil<0.01mg/m³ 、solid <1.00mg/m³ 、dew point 0.6Mpa -20℃ Natural gas: Standard pressure is medium pressure 80kPa Tap water: Pressure≥1.5Kg/㎝2 Heating energy: Electricity, natural gas Note: Above data for reference only, the actual data will be calculated according to customer require -

Brand Name Attractivechina Dimension(L*W*H) Customized Design Place of Origin Guangdong, China Advantage High-efficiency,environmental-protection Production Capacity Depending on customer needs After-sales Service Provided Engineers available to service machinery overseas Product certificate EAC/CE,ISO14001,ISO45001,1SO9001

Related Products