Related News

18

2024

-

10

Automation of the coating process: How do robots change the coating production line?

Author:

Chuangzhi Coating

With the advent of Industry 4.0, the application of automation technology in various industries has gradually become popular, and the coating industry is no exception. The automation of the coating process, especially the use of robots, is constantly changing the coating production line. Linda will lead everyone to explore the current status of automation in the coating process, the application of robots in coating, and the advantages and challenges it brings.

Ⅰ. Traditional methods and current status of the coating process

The traditional coating process usually relies on manual operation, which not only leads to low production efficiency, but also the inconsistency of coating quality is also a prominent problem. Manual operation is easily affected by many factors, including the technical level of the operator, changes in the working environment, etc. In addition, manual coating also has hidden dangers in terms of safety, especially when dealing with harmful chemicals, the health and safety of workers are difficult to guarantee.

Against this background, many companies have begun to seek to improve production efficiency and coating quality through automation. Modern coating production lines are increasingly adopting robotics to replace some or all manual operations. This transformation not only improves the production process, but also brings considerable economic benefits to enterprises.

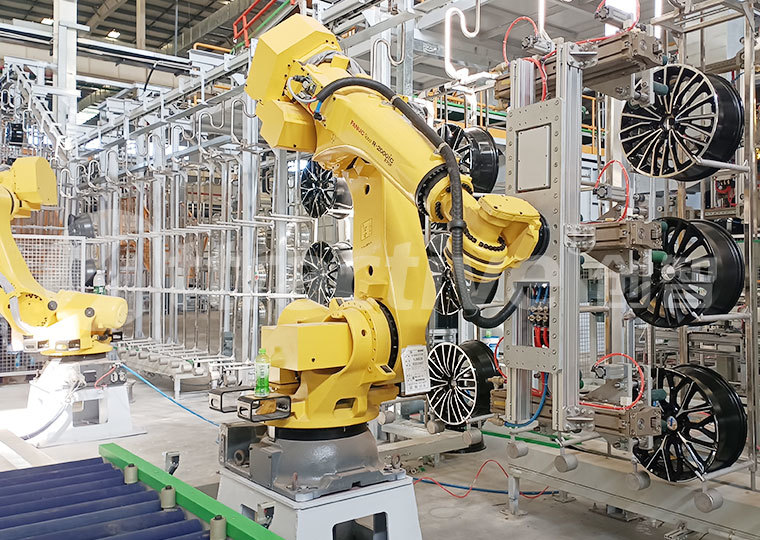

Ⅱ. Application of robots in coating production lines

1.Spraying robots: Spraying robots are one of the most commonly used automation equipment in the coating industry. They can precisely control the speed, angle and amount of spraying to ensure that each layer of paint is evenly coated. In addition, coating robots are able to paint on different surfaces and shapes, which makes them widely used in automobiles, home appliances, furniture, cookware and other fields.

2.Handling and positioning robots: In the coating process, the handling and positioning of workpieces is an important link. The handling robot can efficiently deliver the workpiece to the coating area and move it to the next process after the coating is completed. This not only improves production efficiency, but also reduces the risk of damage to the workpiece during the production process.

3.Cleaning and maintenance robots: The coating production line needs to be cleaned and maintained regularly to ensure the normal operation of the equipment. The cleaning robot can automatically complete the cleaning work without affecting production, reducing labor costs and improving safety.

Ⅲ. Advantages of coating automation

1.Improve production efficiency: The robot can work 24 hours a day without interruption, which greatly improves production efficiency. Compared with manual operation, the consistency of the robot in spraying speed and quality can significantly shorten the production cycle.

2.Improve coating quality: The robot can accurately control various parameters in the spraying process through preset programs. This high degree of controllability greatly improves the uniformity and consistency of the coating and reduces defects caused by human factors.

3.Reduce labor costs: Although the initial investment in robots is high, in the long run, automation can significantly reduce labor costs. While saving labor, companies can also reduce training costs caused by employee mobility.

4.Improve safety: Chemicals used in the coating process are often dangerous. Robots can replace manual labor for dangerous operations, reduce the risk of workers being exposed to harmful substances, and thus improve work safety.

IV. Challenges

Although robots bring many advantages to coating production lines, companies still face some challenges in the process of implementing automation.

1.Initial investment cost: The purchase and installation of robots and related automation equipment requires a high initial investment, which may be a burden for some small and medium-sized enterprises.

2.Shortage of technicians: As the level of automation increases, the demand for technicians is also increasing. However, many companies are currently facing a shortage of technicians in this field, which makes it more difficult to maintain and manage automation systems.

3.Equipment maintenance and updates: Automation equipment requires regular maintenance and upgrades to maintain its optimal performance. Enterprises need to develop effective maintenance plans to ensure the stable operation of equipment.

The automation of coating production lines, especially the application of robotics, not only improves production efficiency and coating quality, but also reduces labor costs and safety risks. Despite some challenges, the future of the coating industry will surely be brighter with the continuous development of technology and the continuous adaptation of enterprises.

In short, the automation of the coating process is an inevitable trend in the development of the industry. In this transformation process, Chuangzhi Coating will help the development of the coating industry, promote the application of advanced technologies and enrich the practical sharing of cases, and help enterprises improve their competitiveness.