13

2024

-

11

Maximizing Efficiency with Wheel Hub Coating Lines: A Comprehensive Guide

Author:

Chuangzhi Coating

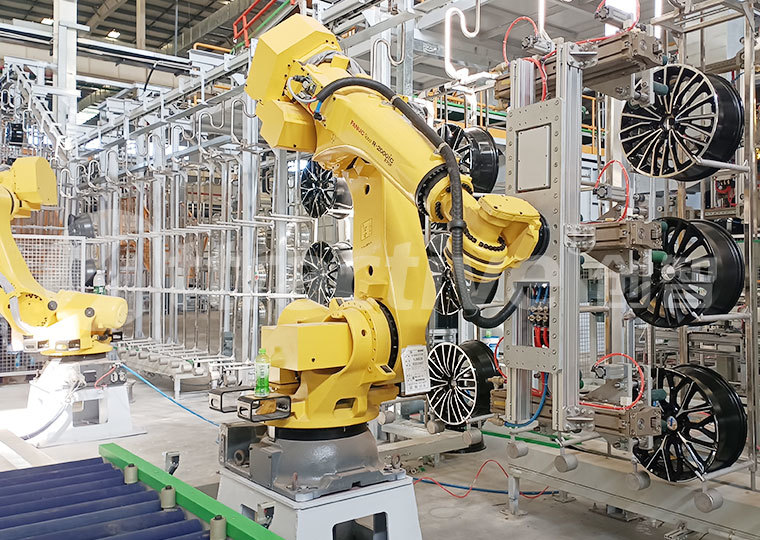

In the industrial equipment and components sector, specifically in the painting and coating production line domain, the wheel hub coating line plays a critical role in enhancing product durability and aesthetics. Understanding the mechanics and benefits of these specialized lines is essential for manufacturers looking to improve their production efficiency and output quality.

A wheel hub coating line is designed to apply protective and decorative coatings to wheel hubs, which are crucial components in automotive and other applications. These lines typically incorporate several stages, including pre-treatment, coating application, curing, and cooling. Each stage is essential for ensuring that the coatings adhere correctly and provide the desired properties, such as corrosion resistance and visual appeal.

One of the primary benefits of a dedicated wheel hub coating line is the ability to streamline the coating process. Unlike manual or less specialized methods, an automated coating line can significantly reduce labor costs and production times. The automation allows for consistent application of coatings, minimizing defects and ensuring uniformity across products. This consistency not only enhances the quality of the final product but also reduces the need for rework, further improving efficiency.

Moreover, the technological advancements in coating application techniques, such as electrostatic spraying or powder coating, have revolutionized the industry. These methods ensure that coatings are applied evenly and adhere effectively to the surface of the wheel hubs. By adopting modern coating technologies, manufacturers can achieve higher transfer efficiency, meaning less material waste and lower environmental impact.

Another significant consideration when setting up a wheel hub coating line is the choice of materials and coatings. Various types of coatings are available, each with unique properties suitable for different applications. For instance, epoxy coatings offer excellent adhesion and chemical resistance, making them ideal for automotive hubs exposed to harsh environments. In contrast, polyurethane coatings provide a high-gloss finish and enhanced UV resistance, which is beneficial for aesthetic purposes.

Furthermore, environmental regulations and sustainability practices are increasingly influencing the design and operation of coating lines. Implementing water-based or low-VOC (volatile organic compound) coatings can help manufacturers comply with regulations while also appealing to environmentally conscious consumers.

In conclusion, investing in a wheel hub coating line is a strategic decision that can lead to significant improvements in operational efficiency and product quality. By understanding the technology, benefits, and material choices involved, manufacturers can optimize their production processes and meet the evolving demands of the market. Whether you're looking to upgrade existing equipment or establish a new production line, recognizing the importance of a dedicated wheel hub coating line is crucial for staying competitive in today's industrial landscape.