Related News

27

2025

-

03

Intelligent Coating Line: The Technological Path for Manufacturing Transformation and Upgrading

Author:

Chuangzhi Coating

With the deepening application of Industry 4.0 technologies, traditional coating lines are facing dual pressures of efficiency bottlenecks and environmental compliance. To address these challenges, manufacturing enterprises are accelerating intelligent transformation, leveraging automation, digitalization, and green technologies to enhance production efficiency, reduce operational costs, and meet increasingly stringent environmental requirements.

I. Core Challenges of Traditional Coating Lines

Low Production Efficiency: Reliance on manual operations leads to unstable production cycles, making it difficult to meet large-scale, high-precision coating demands.

Severe Resource Waste: Traditional spraying processes achieve less than 70% coating material utilization, resulting in material loss and increased costs.

High Environmental Compliance Pressure: Excessive emissions of VOCs (volatile organic compounds) and dust pose regulatory risks.

Inconsistent Product Quality: Manual operations often cause uneven coating thickness, color discrepancies, sagging, and other defects, making it challenging to ensure product qualification rates.

II. Technical Solutions for Intelligent Coating Lines

To address these issues, modern intelligent coating lines can achieve upgrades through the following key technologies:

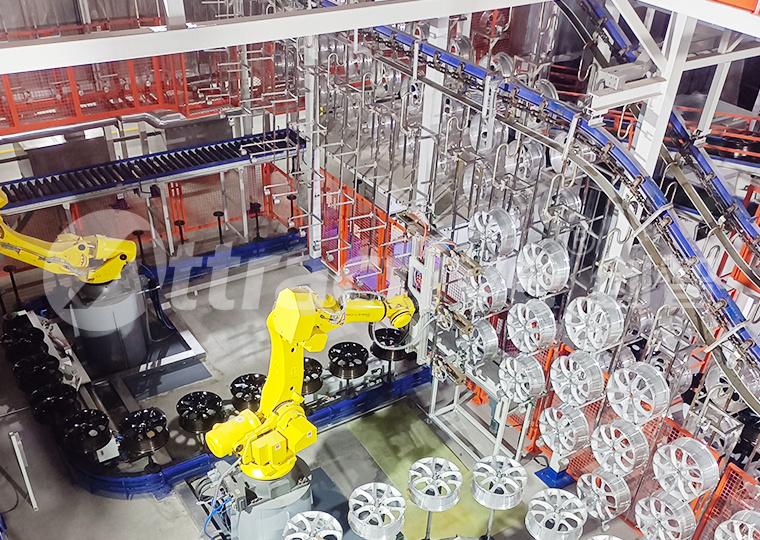

Automated Spraying Systems

Utilize six-axis robots or high-precision robotic arms combined with 3D visual positioning technology to achieve uniform coating on complex surfaces, improving consistency.

Adaptive spraying parameter adjustments reduce overspray, increasing coating material utilization to over 85%.

Intelligent Paint Supply Systems

Integrate dynamic mixing and closed-loop control technologies to ensure stable parameters such as viscosity and temperature, minimizing material waste.

Centralized paint supply systems shorten color-change times and enhance production line flexibility.

Environmental Treatment Systems

Employ high-efficiency exhaust treatment technologies such as RTO (Regenerative Thermal Oxidizer) and activated carbon adsorption-desorption, achieving VOC removal rates exceeding 95% to meet environmental standards.

Install dust collection and filtration systems to reduce particulate concentrations in the working environment.

Data Monitoring and Traceability Systems

Based on Industrial Internet of Things (IIoT) technology, real-time data collection of spraying parameters, equipment status, and environmental conditions enables full-process visualization.

Big data analytics optimize processes, improve yield rates, and establish traceable quality management systems.

III. Case Study: Intelligent Transformation of a Furniture Manufacturer in Guangdong

The company’s original coating line relied on manual spraying, suffering from low efficiency, high pollution, and quality fluctuations. Through intelligent upgrades, the following improvements were achieved:

Robotic Spraying System: Two six-axis spraying robots were deployed, achieving precise coating of furniture panels and increasing efficiency by 30%.

Intelligent Paint Supply and Recovery: A closed-loop paint supply system improved material utilization by 20%, saving over 140,000 USD annually.

RTO Exhaust Treatment: VOC emissions were reduced by 90%, meeting national environmental standards.

Digital Management Platform: Real-time production data monitoring reduced the defect rate to below 1%.

IV. Key Success Factors for Intelligent Transformation

The intelligent upgrade of coating production lines is a systematic project requiring attention to the following aspects:

Customized Solution Design: Select appropriate spraying processes based on product characteristics (e.g., metal, plastic, wood).

Equipment Compatibility and Scalability: Ensure seamless integration with existing MES/ERP systems and support future upgrades.

Full Lifecycle Services: Choose experienced coating equipment suppliers offering end-to-end services from design to maintenance.

Intelligent coating production lines have become an inevitable choice for high-quality development in manufacturing. By integrating automation, digitalization, and green technologies, enterprises can significantly enhance efficiency, reduce costs, and achieve sustainable development. In the future, with deeper integration of AI and industrial IoT, coating technology will advance toward higher levels of intelligent decision-making and autonomous optimization.