Related News

23

2025

-

04

How Intelligent Coating Production Lines Achieve Energy Efficiency?

Author:

Chuangzhi Coating

Discover how intelligent coating lines integrate robotics, digital twins, and eco-technologies to reduce costs by 30%+, with actionable implementation roadmaps for manufacturers.

1. Three Pain Points in Traditional Coating

Modern manufacturers face dual pressures of rising costs and environmental regulations:

High Energy Consumption: Coating equipment consumes 40%-50% of total energy, with significant heat loss.

Low Efficiency: Manual spraying at <10m/min, with 15%+ rework rates.

Environmental Risks: VOC fines exceeding $150k/year and wastewater costs at 20%-30% of OPEX.

2. Four Core Technologies of Smart Coating Lines

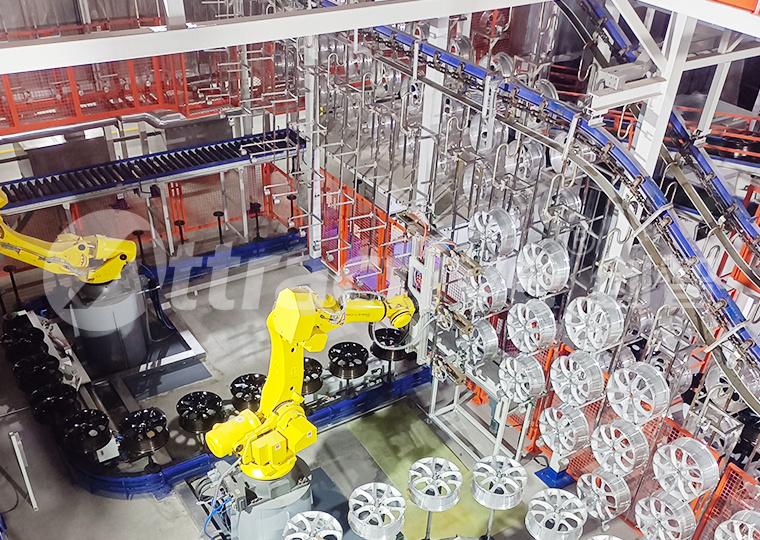

1. Robotic Spraying Systems

6-axis robots with ±0.05mm precision for complex surfaces.

85%+ material utilization via electrostatic atomization.

25m/min operation speed for 24/7 production.

2. Digital Twin Technology

Virtual parameter validation cuts trial costs by 80%.

Real-time thickness monitoring with auto-correction.

3. Modular Energy Design

75% heat recovery from drying ovens.

30% energy savings with VFD drives.

4. Eco Solutions

99% VOC treatment via RTO systems.

95% water reuse with membrane filtration.

3. Implementation Cases

Case 1: Auto Parts Manufacturer

Pain Points: 600k kWh/month, VOC violations.

Solutions:

12 spraying robots

Digital twin management

RTO installation

Results:

35% energy savings ($252k/year)

3% defect rate

6-month ROI

Case 2: Home Appliance Maker

Pain Points: Non-compliance with EU standards.

Solutions:

Water-based coating system

AI inspection

Zero wastewater discharge

Results:

CE/ROHS certification

28% cost reduction

$180k government subsidies

4. Four-Step Implementation Roadmap

Assessment (1-2 months): Energy audits, process mapping.

Design (2-3 months): Digital blueprint, ROI analysis.

Execution (4-6 months): Phased upgrades, VR training.

Optimization (Ongoing): Data-driven process refinement.

5. Future Trends

AI Decision-Making: Self-optimizing spray paths.

Nanocoatings: Dual-function protection.

Energy Integration: Solar-storage hybrid systems.

Conclusion

Intelligent coating lines are redefining manufacturing through technological innovation. Guangdong Chuangzhi has empowered 300+ enterprises with:

30%-45% energy savings

50%-80% productivity gains

100% regulatory compliance

Get your customized solution today!

→ Contact Now