Related News

23

2025

-

05

Energy Consumption Differences Between Powder and Liquid Coatings

Author:

Chuangzhi Coating

This article systematically compares the key differences in energy consumption between powder and liquid coatings. Research shows powder coatings have significant advantages in overall energy consumption, mainly reflected in material utilization, VOC treatment, and curing processes. Data analysis indicates powder coatings can save 30-50% energy consumption while reducing about 60% carbon emissions.

Ⅰ. Overview of Energy Differences

In industrial production, coating energy consumption directly affects operational costs and environmental performance. As two mainstream technologies, powder and liquid coatings show notable energy differences across three stages: production, application, and curing.

Lifecycle assessment reveals powder coatings consume 30-50% less energy overall. This advantage stems from improved material efficiency and reduced solvent processing energy due to their solid form. With tightening environmental regulations, this energy benefit is translating into significant economic value.

Ⅱ. Detailed Energy Comparison

1. Production Energy

Powder coating production is simpler, consuming 0.8-1.2 kWh/kg. The solvent-free process requires less energy. Liquid coatings need complex solvent blending and VOC treatment, consuming 1.5-2.5 kWh/kg - 50-100% higher.

2. Application Energy

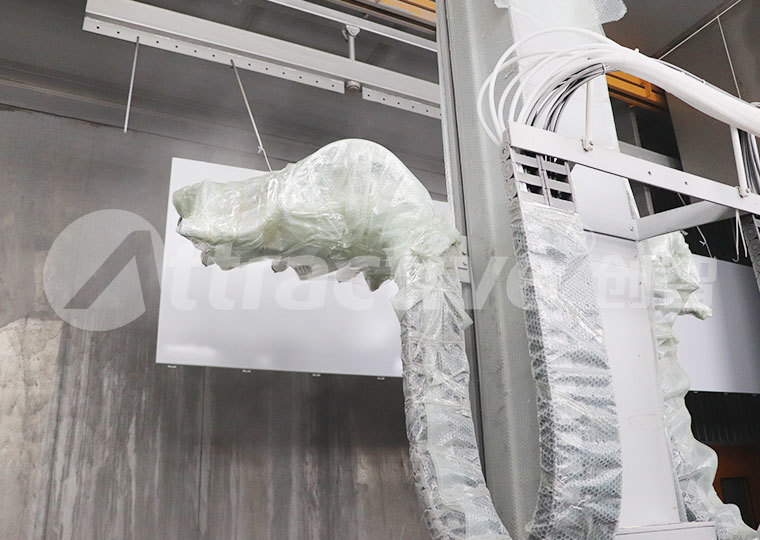

Powder coatings achieve 95-99% material utilization via electrostatic spraying, with minimal waste. Even advanced liquid coating techniques only reach 60-70% utilization, with traditional spraying as low as 30-50%. Per unit area, liquid coatings consume 2-3 times more material-related energy.

3. Curing Energy

Though requiring higher temperatures (180-200°C), powder coatings achieve full coverage in one cure, with modern ovens exceeding 60% thermal efficiency. Liquid coatings cure at lower temperatures (120-160°C) but require multiple applications and VOC venting, resulting in 20-30% higher overall energy use.

Ⅲ. Impacts and Recommendations

Energy differences create economic benefits. A factory coating 1 million m² annually could save 150,000-250,000 RMB (~$21,000-35,000) with powder coatings. While equipment costs are higher, the difference is recoverable within 2-3 years.

Environmentally, powder coatings emit just 40-50% of the CO2 per ton versus liquid coatings. A 500-ton/year facility switching to powder could reduce emissions by 800-1,200 tons while eliminating VOC treatment energy entirely.

Enterprises should evaluate coatings from a lifecycle perspective, prioritizing powder technology for new projects. Government support can accelerate industry greening. With advancing technology, powder coatings' energy advantages will expand further, cementing their position as the leading surface treatment choice.