Related News

10

2025

-

06

How much efficiency can robot spraying improve compared to manual labor?

Author:

Chuangzhi Coating

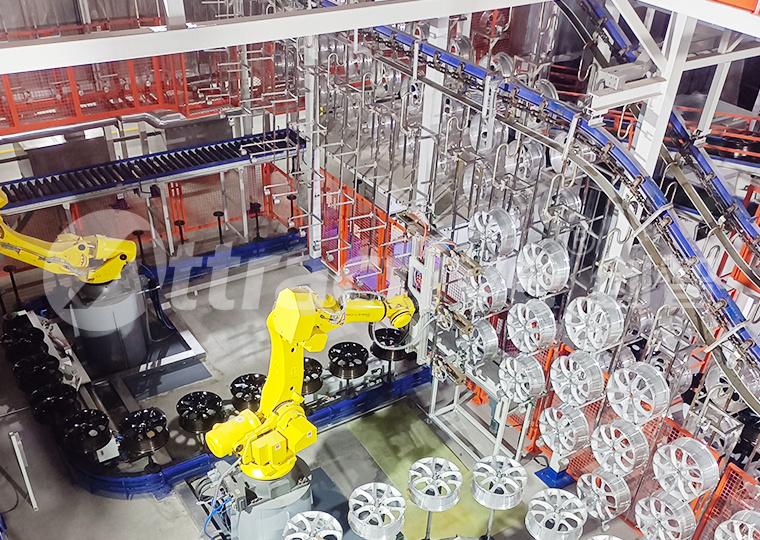

In the field of modern industrial manufacturing, the coating line, as a crucial aspect of product appearance quality, directly relates to a company's production costs and market competitiveness. With the rapid development of technology, robotic spraying technology, with its advantages of high efficiency, precision, and environmental friendliness, is gradually replacing traditional manual spraying and becoming a new frontier for coating line equipment manufacturers to compete for. As a professional coating line equipment manufacturer, we deeply understand the revolutionary efficiency improvements brought about by robotic spraying technology and how it is leading the industry towards a more intelligent and automated future.

I. Robotic Spraying: A Revolutionary Increase in Efficiency

Compared to traditional manual spraying, the increase in efficiency brought about by robotic spraying is evident. Traditional manual spraying is not only time-consuming and labor-intensive but also affected by human factors, making it difficult to guarantee spraying quality. Robotic spraying, with its high speed and precision, significantly improves production efficiency. In the case of locomotive manufacturing, traditional manual spraying of a single carriage often requires eight hours, while robotic spraying can complete the task in just four hours, doubling production efficiency. This means that within the same production time, companies can produce more products, effectively reducing the cost per unit and enhancing market competitiveness.

The high efficiency of robotic spraying is not only reflected in production speed but also in the substantial increase in paint utilization and yield rates. The robotic spraying system integrates an advanced Integrated Painting System (IPS), enabling precise control over spray flow and thickness, ensuring even paint distribution and reducing wasted paint. At the same time, the high precision of robotic spraying improves the film quality and consistency of the product surface, reducing the need for repairs and further boosting production efficiency.

II. Robotic Spraying: The Future Trend of Intelligence

Robotic spraying not only enhances production efficiency but also drives the coating line towards intelligence and automation. Modern robotic spraying equipment often adopts a multi-joint structure and full servo control, providing flexible and reliable operation capable of easily handling various complex-shaped workpiece spraying needs. Additionally, robotic spraying offers strong programmability and flexibility, enabling rapid adjustments and optimizations according to different product types and spraying requirements for flexible production.

Intelligence is another highlight of robotic spraying technology. By integrating advanced sensors and artificial intelligence algorithms, robotic spraying equipment can monitor various parameters in real-time during the spraying process, such as spray speed, thickness, and paint utilization, and make intelligent adjustments based on real-time data to ensure the stability and consistency of spray quality. This intelligent production method not only improves production efficiency but also significantly reduces the impact of human factors on spray quality.

III. Robotic Spraying: A Win-Win for Environmental Protection and Economics

In today's increasingly environmentally conscious world, robotic spraying technology has gained widespread attention for its environmental friendliness and energy-saving features. Compared to traditional manual spraying, robotic spraying can more precisely control paint usage, reducing paint waste and Volatile Organic Compounds (VOCs) emissions and lowering environmental pollution. Meanwhile, the high efficiency of robotic spraying means that companies can reduce the number and size of spraying workshops, further lowering energy consumption and operational costs.

From an economic perspective, although the initial investment cost for robotic spraying equipment is higher, considering its multiple advantages of high efficiency, precision, and environmental friendliness, as well as the cost-saving effects in long-term operation, robotic spraying is undoubtedly a more economical choice. With continuous technological advancements and gradual cost reductions, robotic spraying technology will be widely applied and promoted in more fields.

Conclusion

In summary, robotic spraying technology, with its multiple advantages of high efficiency, precision, and environmental friendliness, is gradually becoming the preferred choice for coating line equipment manufacturers and businesses. As a professional coating line equipment manufacturer, we will continue to dedicate ourselves to the research and innovation of robotic spraying technology, providing customers with more efficient, intelligent, and environmentally friendly coating line solutions. We believe that in the near future, robotic spraying technology will lead the coating industry towards a more intelligent and automated future.