All categories

Related News

16

2025

-

09

Automated Car Parts Painting Line Solutions for OEM Suppliers

Author:

Chuangzhi Coating

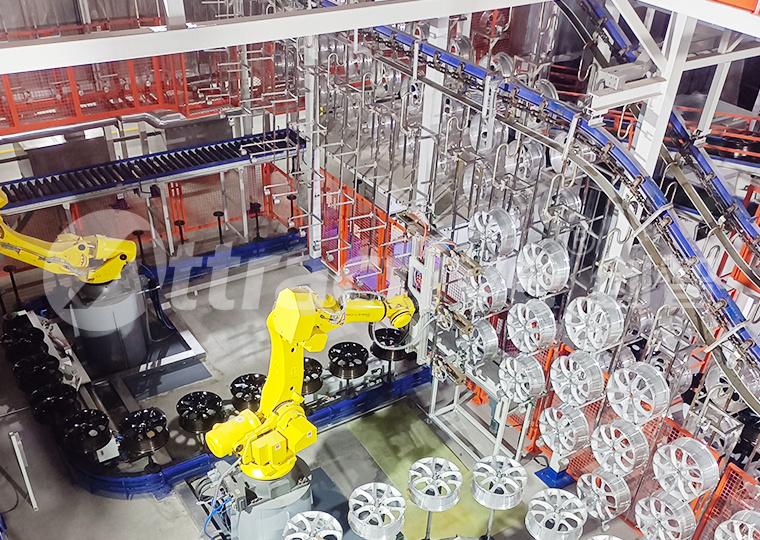

In the automotive manufacturing industry, as core component providers, OEM suppliers' product coating quality directly affects the overall vehicle appearance, durability, and user experience. With the continuous improvement of the automotive industry's requirements for coating precision, production efficiency, and environmental compliance, traditional manual or semi-automated painting lines can no longer meet the large-scale, high-standard production needs of OEM suppliers. As a manufacturer deeply engaged in the coating equipment field, we address the core pain points of OEM suppliers and create a full-process automated painting line solution for automotive parts, covering coating scenarios for various components such as automotive wheels, bumpers, fuel tanks, logos, and interior parts, accurately adapting to the process characteristics of different components.

1. Precision Spraying System to Adapt to Coating Needs of Multiple Component Types

OEM suppliers have significantly different coating requirements for different components: wheels need to balance scratch resistance and appearance gloss (coating thickness deviation ≤ 5μm), interior parts must meet low VOCs and smooth touch standards, and logos have extremely high requirements for color reproduction (color difference ΔE ≤ 0.5). Our automated painting line is equipped with high-precision spraying robots, laser thickness measurement sensors, and color difference detectors, which can real-time match the coating parameters of different components: for the curved surface of wheels, it automatically adjusts the spray gun angle to achieve 360° all-round spraying; for small logo parts, it adopts micro-flow spraying technology to accurately control paint consumption and avoid paint overflow at the edges; for interior parts (such as instrument panel panels), it switches to soft mist spraying mode to ensure a smooth surface touch.

At the same time, the painting line adopts 3D visual positioning technology, which scans the shape of components through cameras—whether it is the complex structure of multi-spoke wheels, the curved arc of fuel tanks, or the uneven texture of bumpers, it can generate exclusive spraying paths, avoiding missing or re-spraying caused by differences in component shapes, and ensuring that the coating consistency of different types of components in the same batch reaches over 99.5%.

2. Efficient Production Process to Cope with Mixed Production of Multiple Components

OEM suppliers often need to handle coating orders for multiple types of components such as wheels, bumpers, and interior parts at the same time. Traditional painting lines have long changeover times and low capacity utilization. Our automated painting line realizes rapid changeover through modular design: for wheels, it is equipped with adjustable hangers to adapt to different sizes from 15 to 22 inches; for bumpers, it uses exclusive clamping devices to avoid deformation during spraying; for fuel tanks and interior parts, it switches to small-part conveying tracks to flexibly adjust the production rhythm. The paint supply system is equipped with multi-color storage tanks and quick-cleaning pipelines, and the changeover time from spraying black wheels to beige interior parts is shortened to less than 30 minutes, which is 50% more efficient than traditional equipment.

In addition, the painting line integrates an intelligent scheduling system that can connect to the OEM supplier's ERP system and automatically schedule production according to order priority: it gives priority to urgent logo part orders, while arranging batch coating of wheels and bumpers, and rationally allocates the capacity of each workstation; it optimizes the baking temperature and time through data analysis (e.g., wheels require 180℃ curing for 30 minutes, while interior parts only need 80℃ curing for 15 minutes), increasing the comprehensive capacity utilization rate of the painting line to over 85% and reducing the coating cost per component by 15%-20%.

3. Compliant Environmental Design to Meet Coating Standards of Multiple Components

Different components have different focuses on coating environmental protection requirements: interior parts must meet the in-vehicle air quality standard (VOCs emission ≤ 100mg/m³), wheels and bumpers need to meet outdoor weather resistance and corrosion resistance requirements, and fuel tanks have strict regulations on coating sealing. Our automated painting line controls environmental protection and performance from the source: it adopts a high-solid-content coating compatible system, supporting the spraying of coatings with a solid content of more than 80%, and the VOCs emission of interior part coating is reduced by 60% compared with traditional solvent-based coatings; it is equipped with an RTO regenerative thermal oxidation device and an activated carbon adsorption system, with a waste gas treatment efficiency of 99%, complying with domestic and foreign environmental standards.

For the needs of special components, the painting line adds exclusive process modules: the fuel tank coating adds a coating sealing detection link to ensure no leakage through air pressure testing; the logo parts use ultraviolet curing technology after spraying to improve color fastness; the wheels add a phosphating pretreatment module to enhance the adhesion between the coating and the metal surface, and the salt spray resistance test can reach more than 1000 hours. At the same time, the drying room adopts heat pump heating technology, with a waste heat recovery rate of 70%, and the overall energy consumption is 25% lower than that of traditional painting lines, helping OEM suppliers achieve green production.

Conclusion

For OEM suppliers, an automated painting line that adapts to multiple types of components and is stable and efficient is the key to ensuring supply chain competitiveness. Our solution, through precise spraying, efficient processes, and compliant design, can not only meet the differentiated coating needs of wheels, bumpers, fuel tanks, logos, and interior parts but also help OEM suppliers reduce costs, improve efficiency, and enhance product quality, enabling them to gain an advantage in the automotive supply chain. In the future, we will continue to focus on technological innovation and provide OEM suppliers with more customized coating solutions that are in line with the development trend of the industry.

Next Page