Related News

05

2026

-

02

Alloy Wheel Painting Line: Comprehensive Analysis and FAQs

Author:

Chuangzhi Coating

Alloy Wheel Painting Line FAQs

Q1: What is an alloy wheel painting line, and what is its core composition?

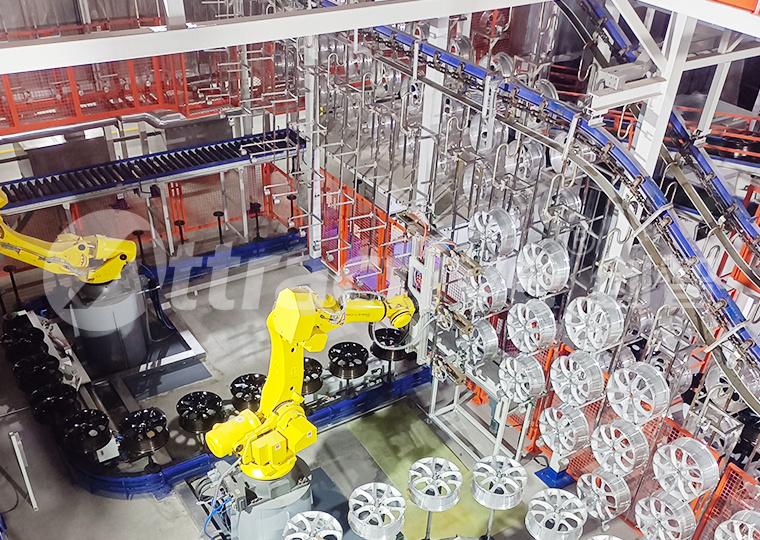

A: An alloy wheel painting line is a complete automated production system specifically designed for the surface treatment of aluminum alloy wheels. It is more than just simple spraying equipment; it is an integrated system solution encompassing pre-treatment, spraying, curing, inspection, and material handling.

An advanced alloy wheel painting line typically includes the following core modules:

Automated Pre-treatment System: Includes processes like degreasing, etching, and conversion coating (e.g., chrome-free zirconium-based) to create a solid foundation for coating adhesion.

Intelligent Spraying Unit: Multi-axis robots equipped with high-performance rotary bells, paired with precise paint supply and color-change systems, achieve highly uniform application.

High-Efficiency Curing Oven: Utilizes multi-zone temperature control technology to ensure perfect curing of powder or liquid coatings.

Quality Inspection and Data Traceability System: Integrates online inspection for film thickness, gloss, etc., and links with MES systems.

Environmental Treatment Equipment: Such as RTO (Regenerative Thermal Oxidizer) systems, ensuring production complies with environmental regulations.

This customized coating solution aims to balance high output, superior quality, and low VOC emissions.

Q2: What are the main advantages of an automated alloy wheel painting line compared to traditional manual spraying?

A: Automated painting lines bring revolutionary improvements, primarily reflected in:

Ultimate Quality Consistency: Robotic spraying offers extremely high repeatability, ensuring identical film thickness, color difference, and gloss for every single wheel, meeting the stringent standards of top-tier OEMs. This is unattainable with manual operation.

Significantly Improved Production Efficiency: A modern automated painting line can operate continuously and stably 24/7, with precise cycle times. Annual capacity can reach hundreds of thousands or even millions of units, forming the cornerstone of large-scale production.

Substantial Reduction in Total Cost:

Material Cost: Electrostatic spraying combined with closed-loop recovery systems can increase paint utilization to over 90%.

Labor Cost: Reduces reliance on skilled painters and lowers training and management costs.

Quality Cost: Extremely low defect and rework rates save significant hidden costs.

Exceptional Environmental and Safety Performance: Enclosed automated spray booths and efficient end-of-pipe treatment systems effectively capture and treat VOCs, protect employee health, and easily pass environmental audits.

Strong Production Flexibility: By quickly switching robot programs, the line can flexibly adapt to multi-variety, small-batch orders, supporting rapid iteration of wheel designs.

Q3: What capabilities of a supplier should be prioritized when selecting an alloy wheel painting line?

A: Selecting a painting line is a strategic investment. Focus on evaluating the supplier's following "turnkey" capabilities:

Process Understanding and Customization Ability: Whether the supplier has a deep understanding of the special requirements of wheel coating (e.g., high-gloss silver, matte black, two-tone effects) and can provide a customized coating solution, rather than simply assembling standard equipment.

Maturity of Core Technology and Equipment: Pay close attention to the practical application cases and performance data of their core technologies, such as robot path optimization algorithms, spray booth airflow design, and thermal energy recovery efficiency.

Level of Automation and Intelligence Integration: Whether the production line possesses genuine intelligent features, such as adaptive adjustment of process parameters, predictive maintenance, and full-process quality data traceability.

Localized Service and Support System: Evaluate the professionalism of their installation/commissioning team, spare parts inventory response speed, and long-term process support capability, which directly impact the stable operation of the line.

Success Cases and Industry Reputation: Conduct on-site visits to their successful projects with similar scale and requirements, which is the most reliable reference.

Q4: Environmental requirements for wheel coating are increasingly strict. How does a production line comply?

A: Meeting environmental requirements is the "entry ticket" for modern painting lines. Advanced industrial painting lines primarily achieve green production through the following methods:

Source Substitution: Promote the use of waterborne coatings, high-solid coatings, or powder coatings to fundamentally reduce VOC generation.

Process Control: Employ high-efficiency electrostatic spraying technology and overspray recovery systems (e.g., limestone powder or Venturi wet scrubbers) to minimize paint loss and emissions.

End-of-Pipe Treatment: Configure efficient exhaust gas treatment equipment, such as RTO (Regenerative Thermal Oxidizer), which thermally decomposes collected organic gases at high temperatures, achieving purification efficiency of over 99%.

Resource Recycling: Integrate heat recovery systems to use waste heat from curing ovens for pre-treatment drying or workshop heating, significantly reducing overall energy consumption.

An excellent painting line should incorporate environmental design throughout, achieving a unity of economic and environmental benefits.

Q5: How to evaluate the Return on Investment (ROI) of an alloy wheel painting line?

A: ROI assessment should go beyond the equipment itself and involve a total lifecycle cost analysis:

Direct Cost Savings: Calculate the annual savings from increased paint utilization, reduced labor, and lower defect rates.

Capacity and Value Enhancement: Assess the growth in customer orders and premium pricing ability resulting from stable quality and on-time delivery.

Environmental Compliance Risk Avoidance: Quantify the value of avoiding fines, production stoppage risks, and enhanced brand image due to compliant emissions.

Flexible Production Value: Evaluate the opportunity value brought by the line's ability to adapt to market changes and quickly respond to new products.

Typically, a well-designed, highly automated painting line can have an investment payback period of 2 to 4 years and is a key asset for enhancing a company's core competitiveness in the long run.

Q6: What are the future trends in alloy wheel coating technology?

A: Future trends will focus on "Smarter, Greener, More Personal":

Digital Twin and Artificial Intelligence: By creating a digital twin of the production line for process simulation and optimization in the virtual world, and using AI algorithms to optimize spraying parameters in real-time, enabling "self-learning" production.

Sustainable Coating Materials: New materials like bio-based coatings and low-temperature cure powders will be widely adopted, further reducing the carbon footprint.

Personalized and Customized Coating: Supporting flexible custom coating for orders as small as a single wheel, meeting personalized needs in the aftermarket, which places higher demands on the flexibility of customized coating solutions.

Integrated Smart Factory: The painting line will be deeply integrated with processes like casting, machining, and inspection, becoming a key data-interconnected node within the smart factory.

Previous