30 Years Experience Coating Line Turnkey System Integrator

Tel: +86 13580616025

10

2019

-

09

Automatic slag system for spray paint room slag treatment system

Author:

Chuangzhi Coating

In the coating industry, the paint slag treatment in the spray booth has always been a headache, because it is related to the recycling efficiency of the paint in the spray booth, the clean and tidy environment, the life of the spray booth, and whether the environmental discharge is up to standard. Therefore, a good paint residue treatment system is particularly important. Today, I will introduce to you the automatic slag system from the spray booth of Attractivechina, so that the treatment of paint residue is no longer a problem!

1. Introduction to automatic slag system

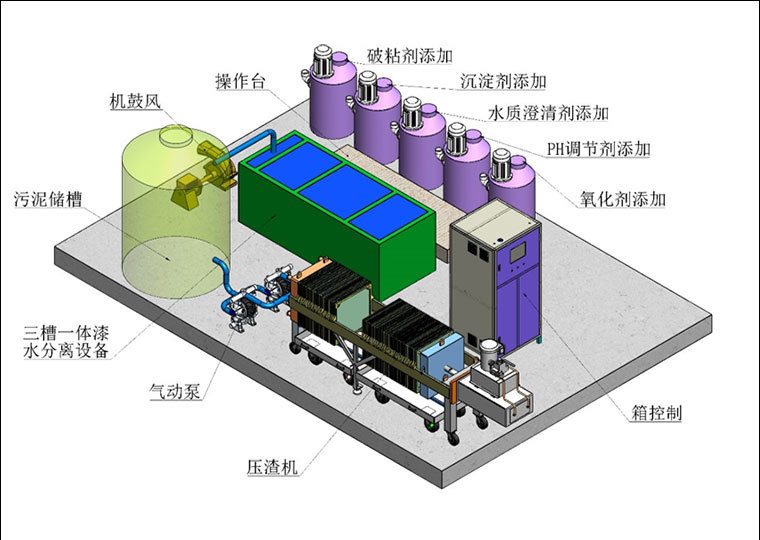

The automatic slag removal system is a device that uses a combination of chemical treatment, physical filtration, and phosgene composite reaction to treat wastewater, and can automatically discharge slag and clean the waste residue through a backwash pump. The main components include the operation console, blower, sludge storage tank, Sancha integrated paint water separation equipment, pneumatic pump, slag crusher, control box, chemical agent addition and so on.

2. Automatic slag system process

(1.) The spray booth is used as an overflow tank to collect the paint water separately. A stirring system is added in the tank to avoid the deposition of paint residue, and the paint water is pumped to the circulating water collection tank.

(2.) Add a stirring system to the collection tank to avoid paint residue deposition.

(3.) Collecting pool circulating water is pumped to the paint water separator. After the drug reaction, the treated water is adjusted to the alkaline range (pH 7~9), the rubber feather is not sticky and the water quality is clear. After precipitation The clean treated water overflows into the clear water area of the collection pool.

(4.) The paint slag sludge in the clean water separation tank is controlled by a pneumatic valve and sent to the paint slag collection tank by means of a pneumatic butterfly valve.

(5.) The paint slag sludge in the paint slag collection tank is pumped to the plate and frame type dewatering machine by pneumatic diaphragm pump, and the slag cake after the pressure filtration is sent to waste treatment; the pressure filtrate overflows into the relay tank, and the pump is used. Pu hits the collection tank.

(6.) In order to ensure the treatment of water quality without odor and microbial growth, an oxidizing agent is added at the outlet of the clear water separation tank every week or when the water is foul-smelling to eliminate odor and decompose some organic substances and sterilize.

(7.) If the recycled water cannot meet the on-site use in the circulating water system, it will be replenished with tap water.

(8.) The main system of the system adopts automatic control, but it is necessary to pay attention to the liquid level of the liquid medicine. The timely replenishment and dehydration machine need to manually open the plate to discharge the paint residue cake.

(9.) Circulating water needs to be treated every day. When the water quality is abnormal, it needs to be strengthened immediately.

(10.) Water quality management should be done on weekdays to avoid the corrosion of the primer residue and the deterioration of water quality, thus shortening the service life of the circulating water.

(11.) This equipment can be used for a long time in the treatment of circulating water, such as water quality.

(12.) The system starts the timer setting, the switch time can be set by the timer; manual operation can be taken when the net is clean.

(13.) Add sewage collection canals on the site, collect the ground sewage and send it to the collection tank to prevent secondary pollution.

3. The effect of the automatic slag system is as follows:

(1.) Improve the cleanliness of the spray booth and reduce the product defect rate;

(2.) The circulating water can be used for a long time without discharge, and the pool has no sinking slag;

(3.) Reducing the manual removal of paint slag and reducing the maintenance period and maintenance time of the spray booth;

(4.) After 3 months, the water content is less than 20%, the water seepage degree is >10cm, and the water quality and paint residue have no pungent odor;

The above is the relevant content of [automatic slag removal system of spray paint room slag treatment system], more information about spray production line, welcome to pay attention to us to get updated information! Watch more videos

automatic slag system

Related News

undefined