Related News

06

2024

-

12

Is the powder coating line much cheaper than the liquid coating line?

Author:

Chuangzhi Coating

In the field of industrial coating, powder coating and liquid coating are two mainstream coating technologies, each with its own unique advantages and applicable scenarios. For many manufacturers, the choice of coating method is often based on a variety of factors, among which cost is a key point that cannot be ignored. So, is the powder coating line really more economical than the liquid coating line? This article will explain from multiple dimensions, in order to provide readers with a comprehensive and objective answer.

Ⅰ. Comparison of initial investment costs

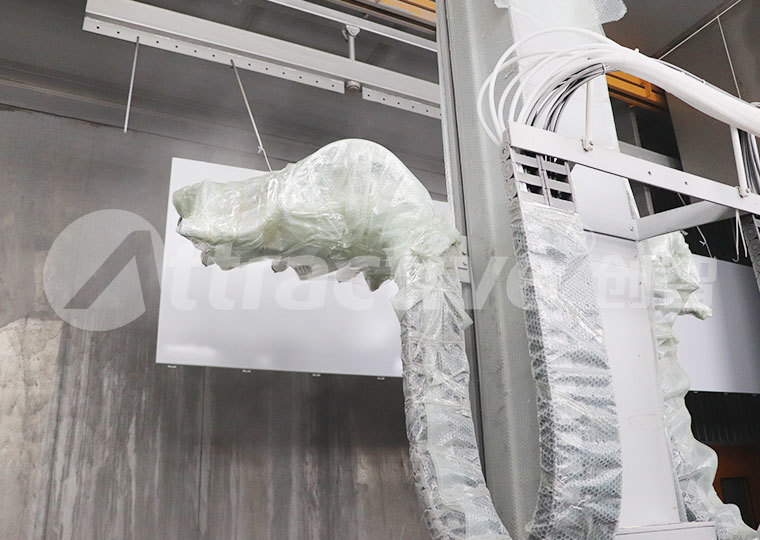

First of all, from the perspective of initial investment, the cost difference between powder coating line and liquid coating line is quite obvious. Powder coating lines usually need to be equipped with professional powder spraying rooms, recovery systems, electrostatic generators, powder screening and supply devices, etc., and the purchase and installation costs of these equipment are relatively high. In contrast, the equipment configuration of liquid coating lines is relatively simple, mainly including spray booths, paint supply systems, pumps and spray guns, etc., and the initial investment cost is relatively low.

However, it is worth noting that with the continuous advancement of technology and the intensification of market competition, the price of powder coating equipment has gradually declined in recent years, and its high efficiency and environmental protection characteristics have made more and more companies willing to invest in it. In addition, the material utilization rate of powder coating is high, which reduces waste and helps to reduce overall costs in the long run.

Ⅱ

In terms of operating costs, powder coating and liquid coating have their own advantages. The material cost of powder coating is usually lower than that of liquid coating, because powder coating has a high solid content, does not need to be diluted, and can be recycled, which greatly reduces material consumption. At the same time, less waste is generated during the powder coating process, and the processing cost is relatively low.

However, liquid coating also has cost advantages in some aspects. For example, for small batch and multi-variety production, liquid coating is more flexible and can quickly change the color and type of coating without the need for complex cleaning and color change operations like powder coating. In addition, the equipment maintenance cost of liquid coating is relatively low because its equipment structure is relatively simple and it is more convenient to repair.

Ⅲ

Production efficiency and quality control are important indicators for measuring the economic benefits of coating lines. Powder coating lines are usually able to achieve automated production, greatly improving production efficiency. At the same time, the coating thickness of powder coating is uniform, the adhesion is strong, and the corrosion resistance is good, which can meet the coating requirements of high-quality products. These advantages make powder coating lines increasingly widely used in industries such as automotive parts, home appliances, and furniture.

In contrast, although liquid coating can also achieve a certain production efficiency, it may face more challenges in coating quality control. For example, liquid coatings are easily affected by factors such as environmental humidity and temperature, resulting in unstable coating quality. In addition, the volatile substances generated during the liquid coating process pose a potential threat to the environment and the health of operators, and additional protective measures need to be taken.

IV. Environmental protection and sustainability considerations

In today's society, environmental protection and sustainability have become important factors that companies must consider when choosing a coating method. Powder coating has excellent environmental protection performance with its low volatile organic compound (VOC) emissions, high material utilization rate, and easy recycling. This not only helps companies reduce environmental pollution, but also reduces the additional costs incurred by environmental regulations.

Although liquid coating is also constantly improving to reduce its impact on the environment, it still has certain challenges in VOC emissions and material waste. Therefore, for enterprises pursuing green production, powder coating line may be a more ideal choice.

To sum up, the comparison between powder coating line and liquid coating line in terms of cost-effectiveness is not generalized. In terms of initial investment cost, liquid coating line is relatively low; but in terms of operating cost, production efficiency, quality control, environmental protection and sustainability, powder coating line shows obvious advantages. Therefore, for manufacturers, the choice of coating method should take into account product type, production scale, market demand, project budget and other factors. If you have sufficient project budget, you can establish two coating lines, powder and liquid, to better meet market demand.

In the end, both powder coating and liquid coating have their unique value and applicable scenarios. The key is how to choose the most suitable coating method according to their actual situation to maximize cost-effectiveness. To learn more, consult Guangdong Chuangzhi!