Related News

13

2025

-

10

Analysis of Powder Coating Production Line Applications in the Automotive Manufacturing Industry

Author:

Chuangzhi Coating

With the continuous development of the automotive industry, vehicle manufacturing demands increasingly stringent requirements for exterior quality, corrosion resistance, and environmental performance. While traditional liquid spray painting processes are mature, they suffer from issues such as high energy consumption, significant pollution, and low efficiency. Powder coating production lines, with their high efficiency, energy conservation, and environmental friendliness, are gradually becoming a key choice for surface treatment in the automotive industry, driving the entire industry towards greener and more intelligent development.

Powder coating processes offer significant environmental advantages. Compared to traditional spray painting, powder coatings are solvent-free and produce virtually no volatile organic compounds (VOCs), fundamentally addressing the issues of air pollution and wastewater treatment during the spraying process. Powder coating of automotive parts not only creates a smooth and uniform surface, but also a dense, highly adhesive paint film, significantly enhancing weather resistance and corrosion resistance. Many automotive manufacturers have adopted powder coating production lines to achieve cleaner and more environmentally friendly production processes, aligning with the global automotive industry's trend towards low-carbon manufacturing.

Powder coating production lines are widely used in automotive parts protection. In vehicle manufacturing, components such as chassis, wheels, bumpers, engine mounts, inner door frames, and seat brackets require rust and corrosion protection. Powder coating can create a sufficiently thick coating in a single application, eliminating the complex and time-consuming process of multiple layers of painting. Electrostatic spraying allows the powder to evenly adhere to the metal surface, achieving excellent coverage even for complexly shaped parts, thereby ensuring consistent and long-lasting coating.

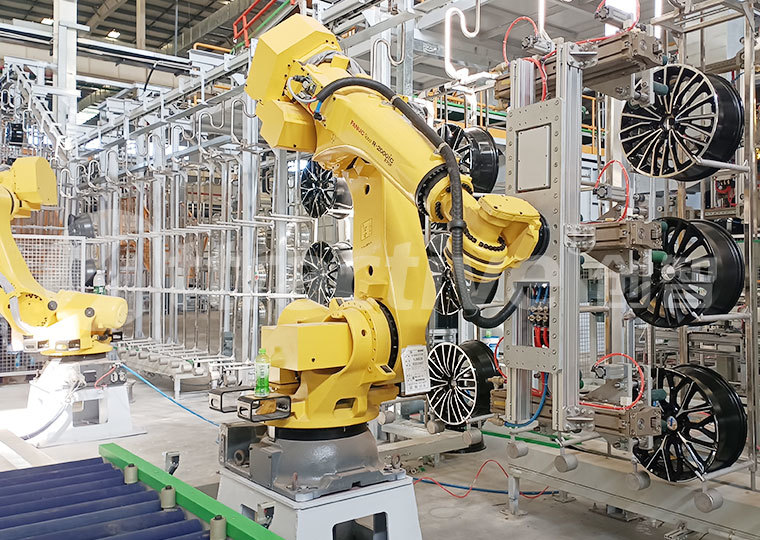

The introduction of automation and intelligent technologies has made powder coating production lines more competitive. Modern automakers often use automated spray robots, conveyor systems, and integrated curing ovens to automate the entire process, from loading, spraying, curing, and unloading. This not only reduces labor costs but also allows for real-time adjustment of spray volume and temperature through data monitoring systems to ensure consistent coating quality. Some high-end production lines also utilize intelligent recognition and adaptive spraying technologies, enabling precise coating of parts of varying sizes and shapes, improving overall production efficiency and consistency.

Powder coating production lines also offer excellent economic benefits. Powder coating boasts a high utilization rate exceeding 95%. Unabsorbed powder can be reused through a recycling system, significantly reducing material waste. Compared to liquid coating, powder coating offers shorter baking times, lower energy consumption, and lower equipment maintenance costs, significantly reducing overall operating expenses. This is undoubtedly a cost-effective option for automotive manufacturers striving for efficiency and cost control.

In the automotive industry, powder coating production lines not only improve product appearance and protective performance but also promote green transformation of the manufacturing process. With its high efficiency, low pollution, and low energy consumption, it has become a crucial process in modern automotive manufacturing. In the future, with the advancement of materials technology and intelligent manufacturing, powder coating technology will continue to be optimized and upgraded, bringing higher quality and more sustainable development to the automotive industry.